Outer ring distributor and manufacturing process thereof

A technology of manufacturing process and fire distributor, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of low melting point, high cost, and non-environmental protection in the manufacturing process, and achieve high combustion energy efficiency, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

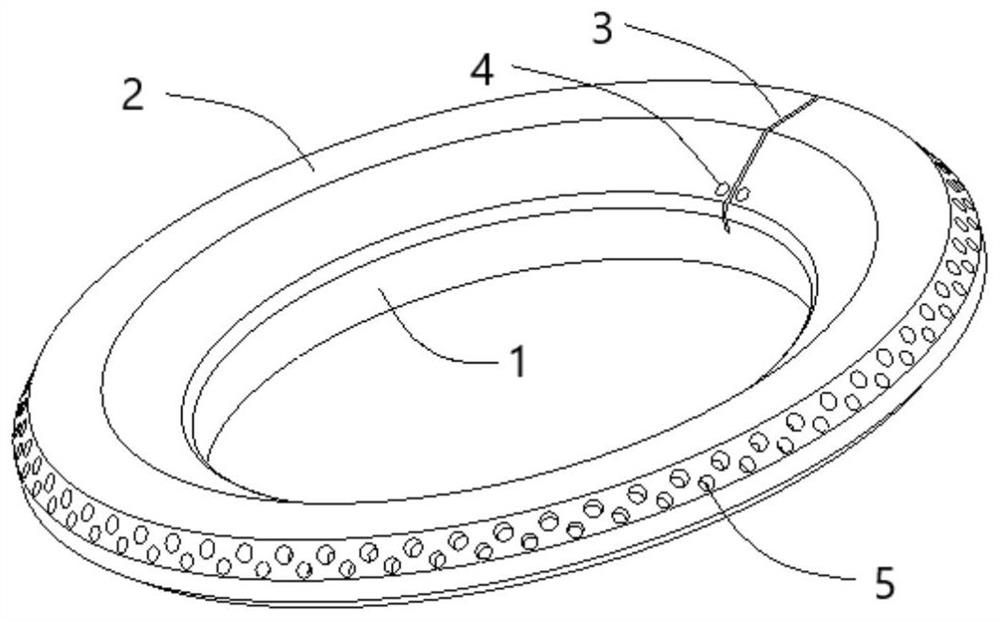

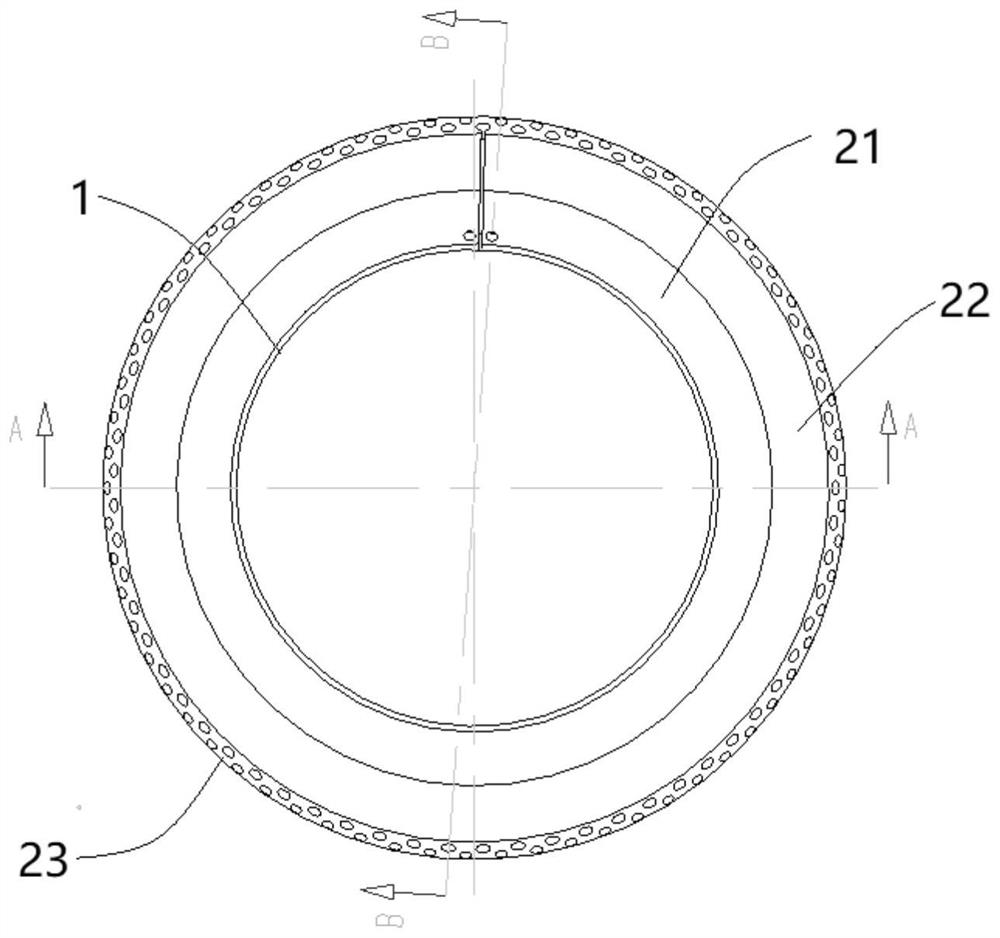

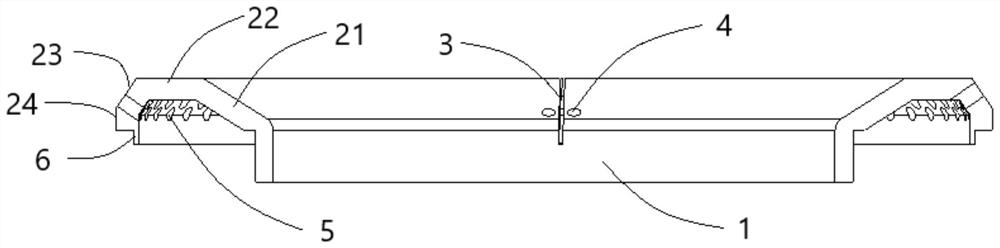

[0027] The outer ring fire distributor provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Such as Figure 1-4 As shown, this embodiment mainly includes an inner side wall 1 and an upper cover 2 having a ring structure, and the upper cover 2 is provided with a fire ignition groove 3, an ignition hole 4 and a fire outlet 5, and the inner side wall 1 and the upper cover 2 The inner wall 1 is formed integrally with stainless steel material, and the inner wall 1 is configured as a ring structure extending in the vertical direction. The upper cover 2 includes an inner slope 21 extending outward from the top of the inner wall 1 obliquely upward. , a top plane 22 extending horizontally outward from the top of the inner slope 21, an outer slope 23 extending obliquely downward from the outside of the top plane 22, and a vertical downward extension from the bottom of the outer slope 23 Outer side wall 24, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com