Method for detecting liquid level position based on surface wave mode conversion

A mode conversion and surface wave technology, applied in measuring devices, liquid level indicators, engine lubrication, etc., can solve problems such as affecting economic benefits, unfavorable production applications, errors, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

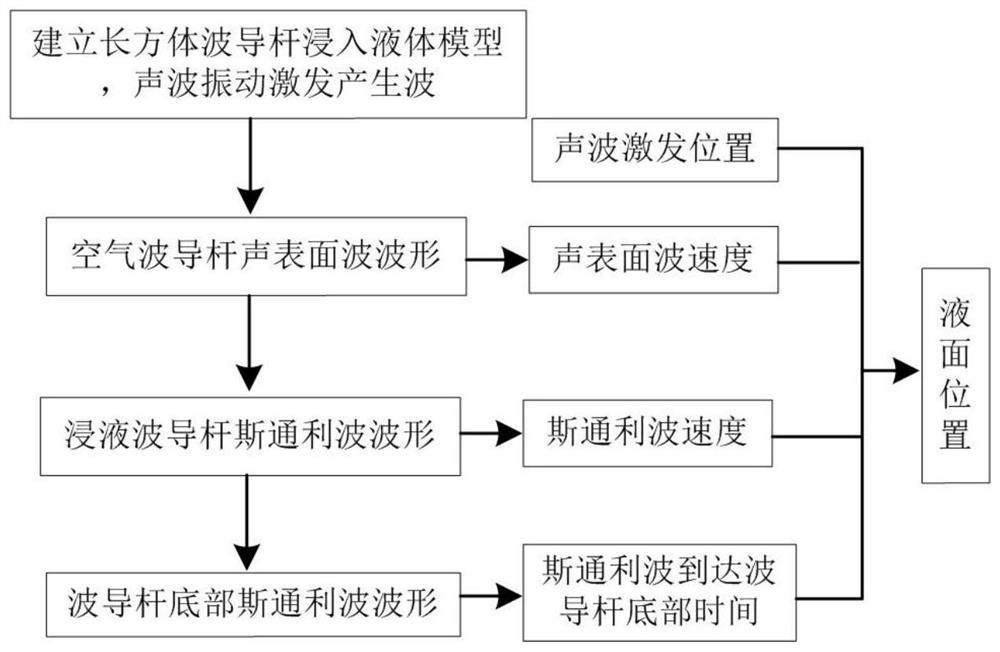

[0026] Such as figure 1 As shown, it is a schematic flow chart of an embodiment of using surface wave mode conversion to detect liquid level position provided by the present invention. A method for detecting liquid level position based on surface wave mode conversion includes the following steps:

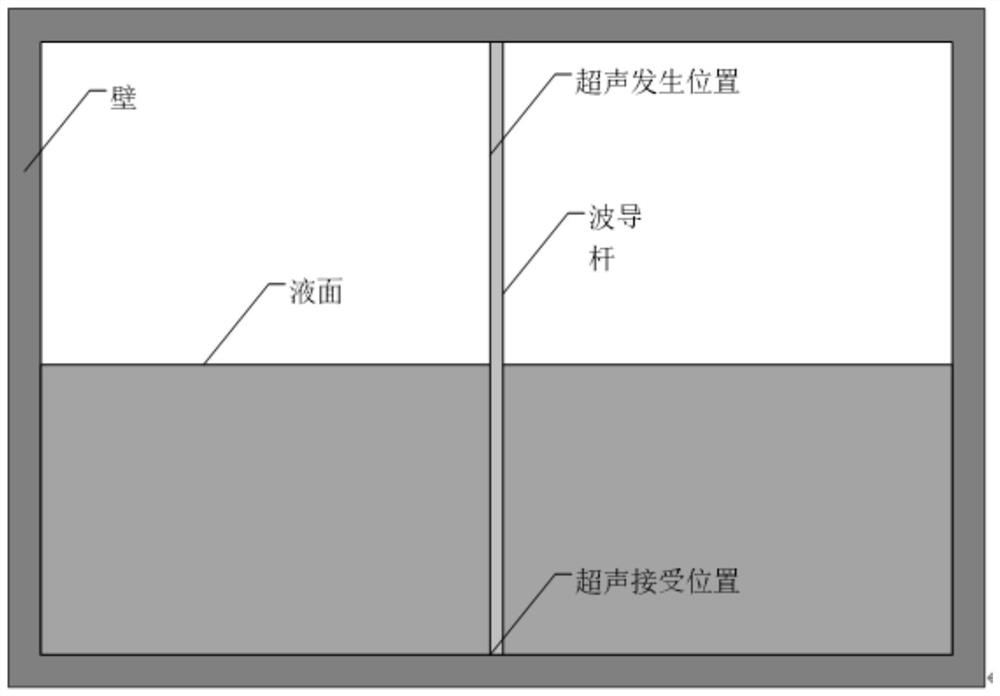

[0027] 1) Establish the waveguide rod model: the cuboid waveguide rod is vertically inserted into the bottom of the liquid, and the ultrasonic vibration is used to excite the surface wave on the surface of the waveguide rod; part of the waveguide rod is immersed in the liquid, and the acoustic wave excitation position is placed in the air.

[0028] 2) Receive the arriving surface acoustic wave on the air waveguide rod;

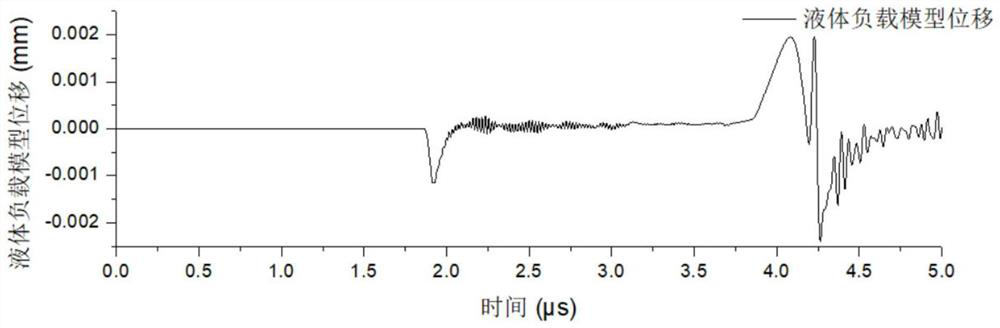

[0029] 3) According to the arrival time of the surface acoustic wave obtained in step 2), the propagation velocity of the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com