Multi-parameter inversion method and device for heterogeneous materials based on automatic image partitioning

An automatic partitioning and heterogeneous technology, applied in the field of multi-parameter inversion of heterogeneous materials, can solve the problems of manual partitioning, insufficient material parameters, complex experimental process, etc., and achieve the effect of improving accuracy and simplifying the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

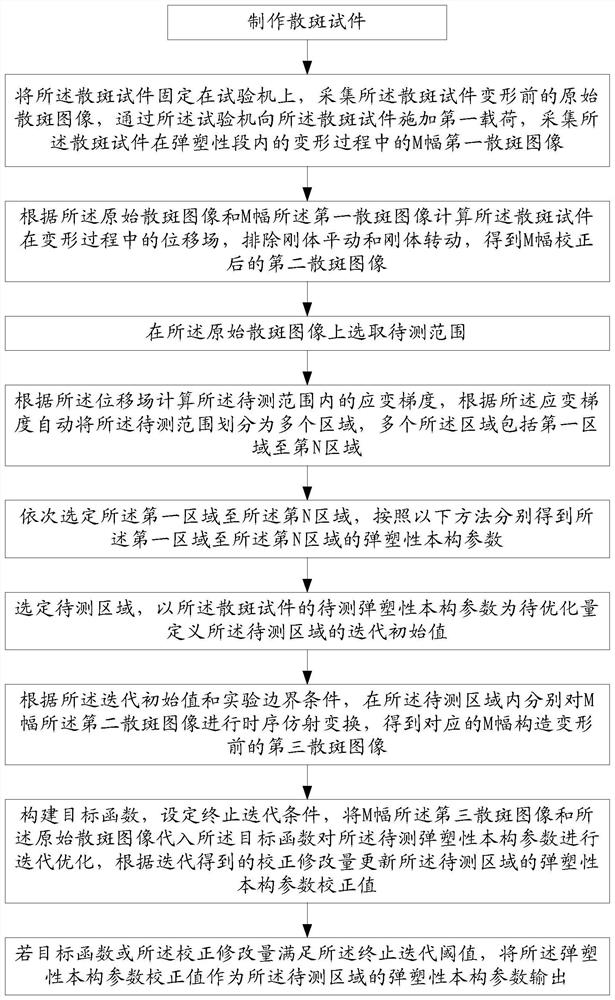

[0078] Combine the following figure 1 A specific embodiment of the multi-parameter inversion method for heterogeneous materials based on automatic image partitioning described in the present invention is described, including:

[0079] S11: making a speckle test piece, where the speckle test piece includes speckle marking points;

[0080] S12: Fix the speckle specimen on the testing machine, collect the original speckle image of the speckle specimen before deformation, apply the first load to the speckle specimen through the testing machine, and collect the deformation of the speckle specimen in the elastic-plastic section M first speckle images in the process, the elastic-plastic segment includes an elastic phase and a plastic phase, and M is a positive integer;

[0081]When the external force is less than the elastic limit load, after the external force causing the deformation is removed, the specimen can completely restore its original shape. This recoverable deformation is...

Embodiment 2

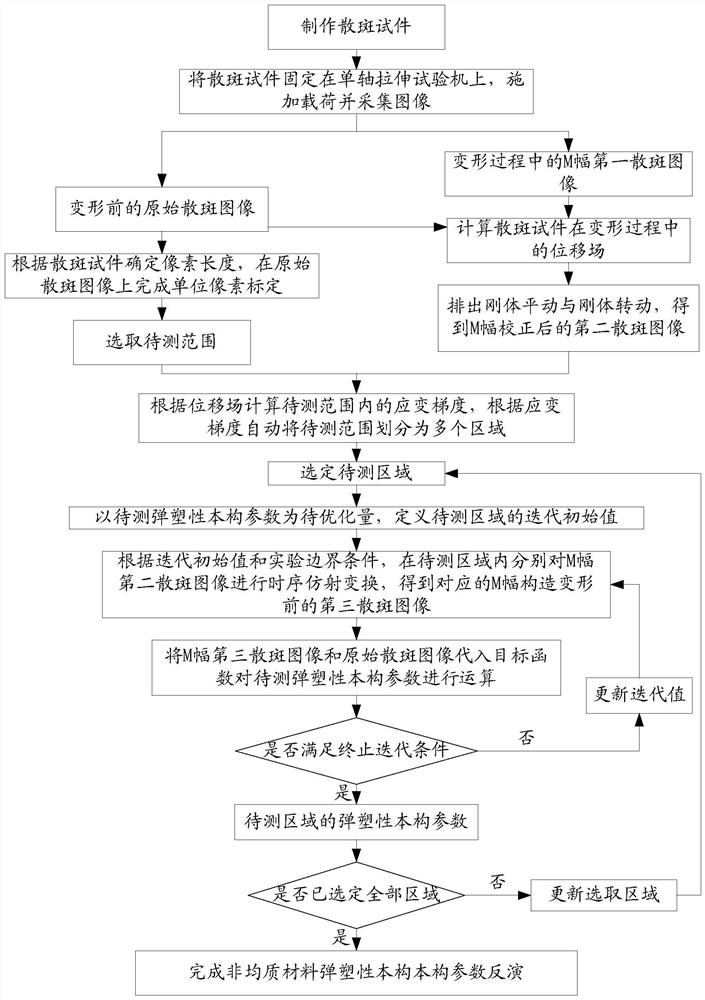

[0097] The following combination figure 2 Another specific embodiment of the multi-parameter inversion method for heterogeneous materials based on automatic image partitioning described in the present invention is described, including:

[0098] S21: making a speckle test piece, where the speckle test piece includes speckle marking points;

[0099] In step S21, the speckle specimen is made in the following manner:

[0100] Spray white paint evenly on the piece to be tested as a white base, wait for the white paint to dry and form a film, and use black paint to evenly spray black speckles on the white base.

[0101] S22: Fix the speckle test piece on the testing machine, collect the original speckle image of the speckle test piece before deformation, apply the first load to the speckle test piece through the testing machine, and collect the deformation of the speckle test piece in the elastic-plastic section M first speckle images in the process, the elastic-plastic segment i...

Embodiment 3

[0178] This is a specific embodiment of the heterogeneous material multi-parameter inversion device based on automatic image partitioning described in the present invention, including:

[0179] The image acquisition module 301, the image acquisition module 301 is coupled with the displacement field calculation module 302, and is used to acquire the original speckle image of the speckle specimen before deformation and to acquire M images of the speckle specimen during the deformation process in the elastic-plastic section The first speckle image is transmitted to the displacement field calculation module 302, where M is a positive integer;

[0180] The displacement field calculation module 302 is coupled to the image acquisition module 301 and the range selection module 303 respectively, and is used to calculate the displacement field of the speckle specimen during the deformation process according to the original speckle image and the M first speckle images, Eliminate rigid bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com