Pneumatic servo positioning device for filling box in anti-explosion environment

A technology of servo positioning and filling boxes, which is applied in the direction of electrical program control, program control in sequence/logic controller, program control, etc., can solve the problems of low automation, harsh environment, and many dangerous workers, and achieve improvement The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

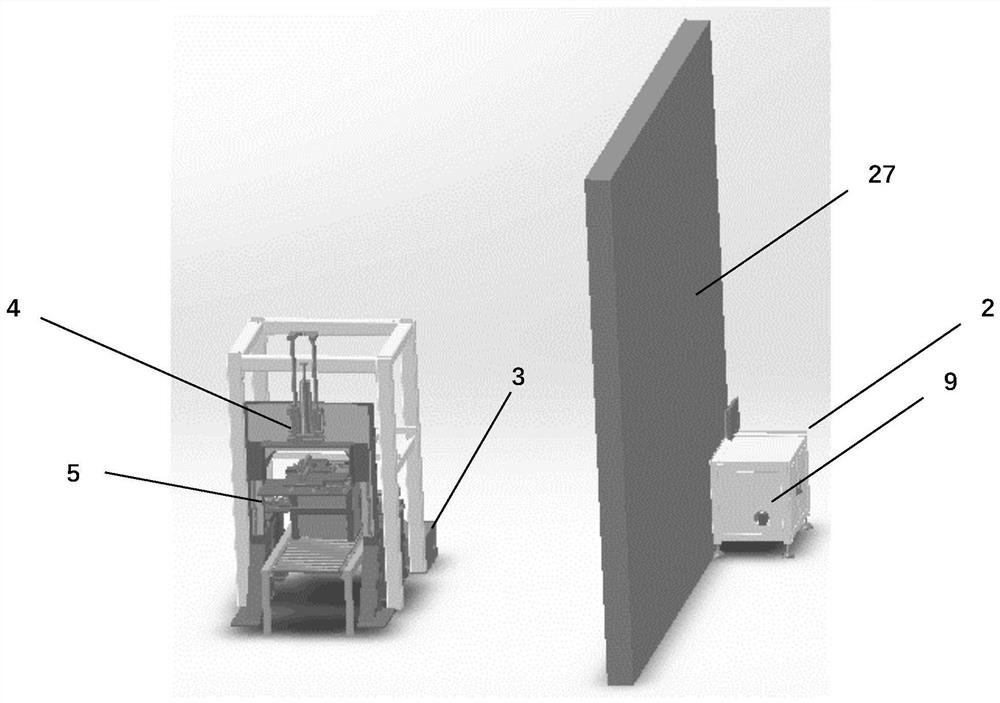

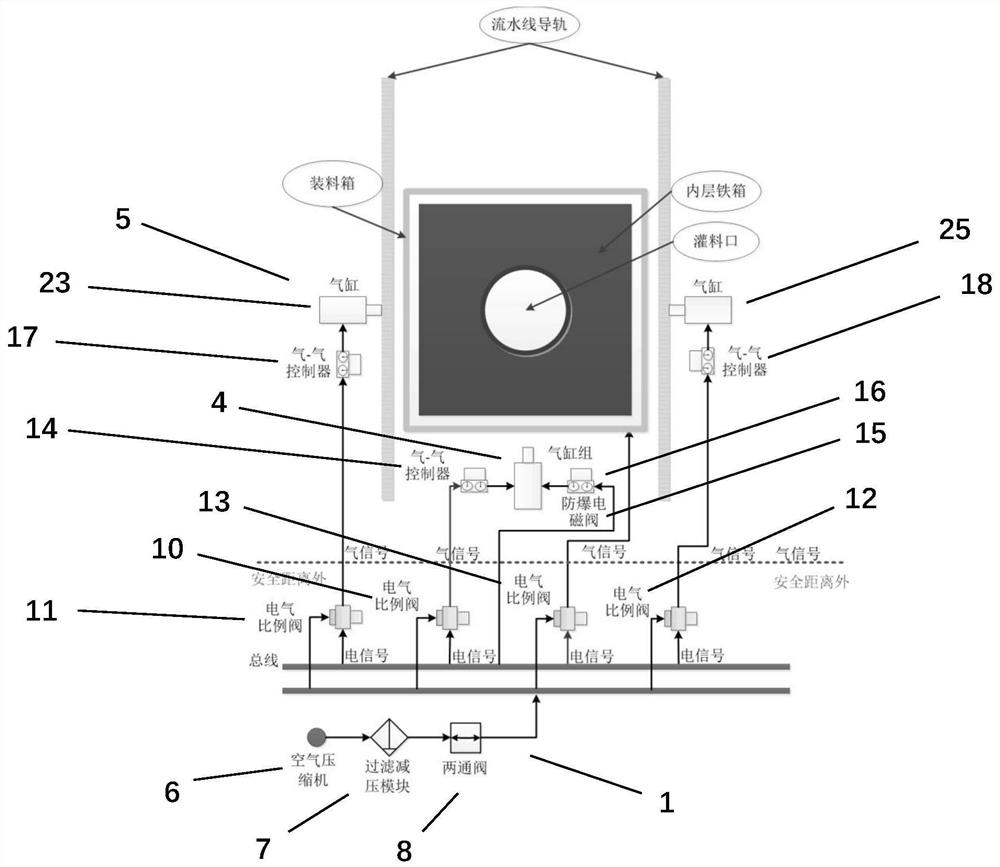

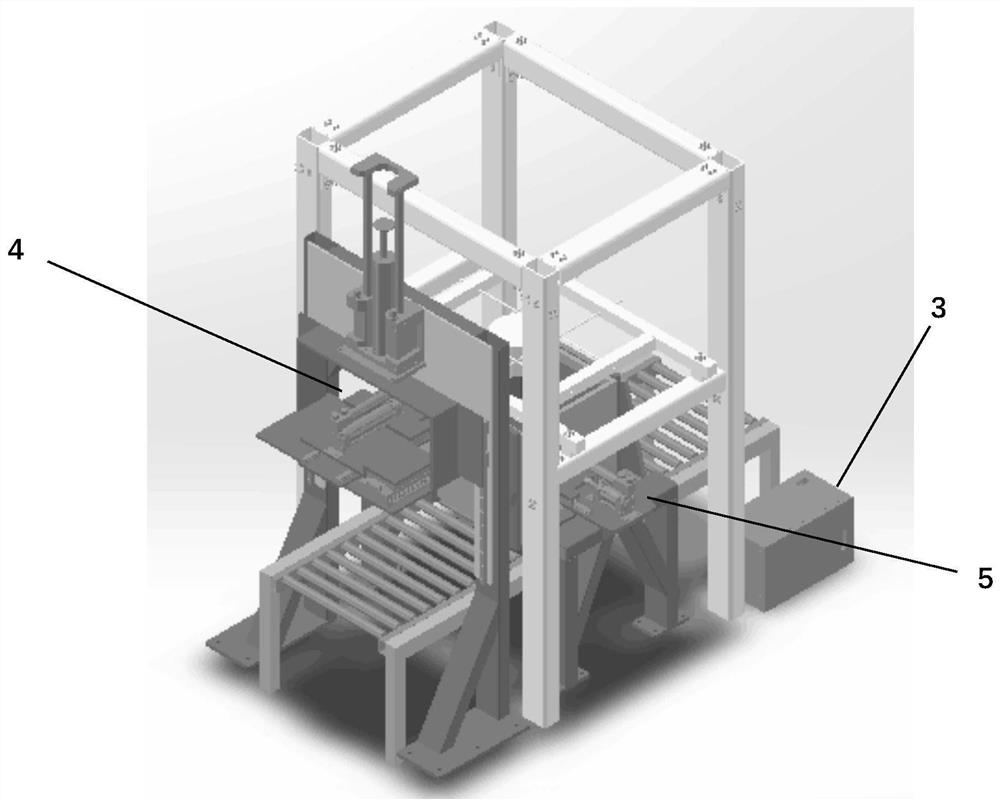

[0023] Such as figure 1 , 2 As shown, the filling box pneumatic servo positioning device provided by the present invention includes an air source module 1, a PLC control cabinet 2, an explosion-proof control cabinet 3, an X direction cylinder group 4 and a Y direction cylinder group 5; the gas source module 1 and the PLC control cabinet 2 is connected through 6mm ventilation pipe and placed outside the factory building; PCL control cabinet 2 is connected with explosion-proof control cabinet 3 in the factory building through CAN serial bus and 6mm ventilation pipe; explosion-proof control cabinet 3 is connected with X direction cylinder group 4 and Y direction cylinder group 5 are connected through explosion-proof relays and explosion-proof connectors; the PLC control cabinet 2 is isolated from the internal devices of the plant through an explosion-proo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com