Drill jumbo telescopic arm limit working condition calculation method

A technology of rock drilling rig and calculation method, which is applied in calculation, calculation model, design optimization/simulation and other directions, can solve the problem that the optimal design result of the telescopic boom cannot meet the actual engineering needs, etc., so as to solve the lack of adaptability and improve the adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

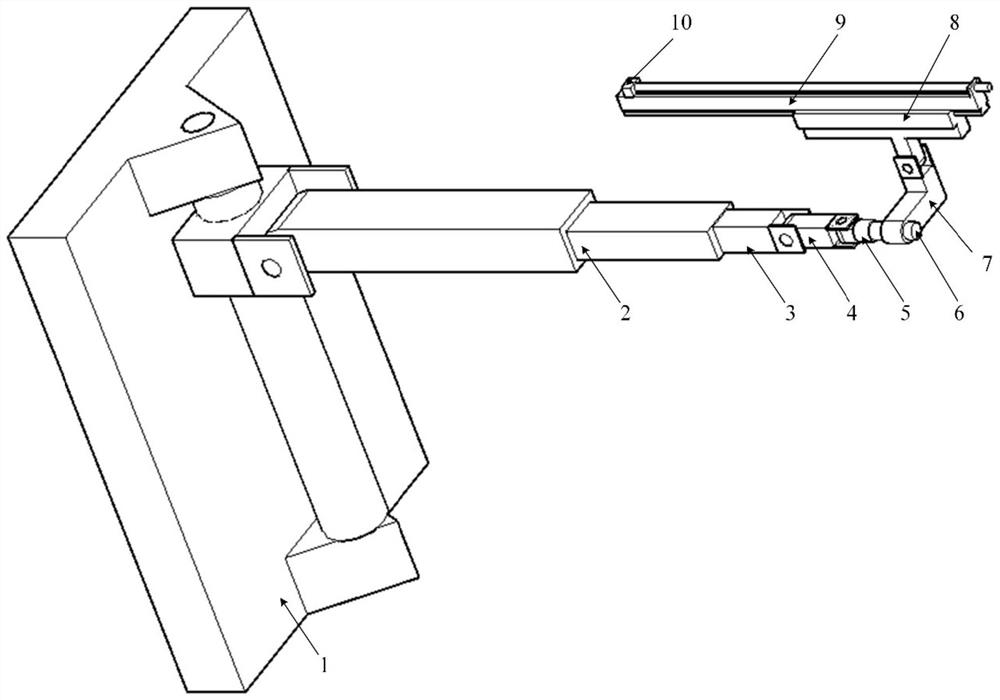

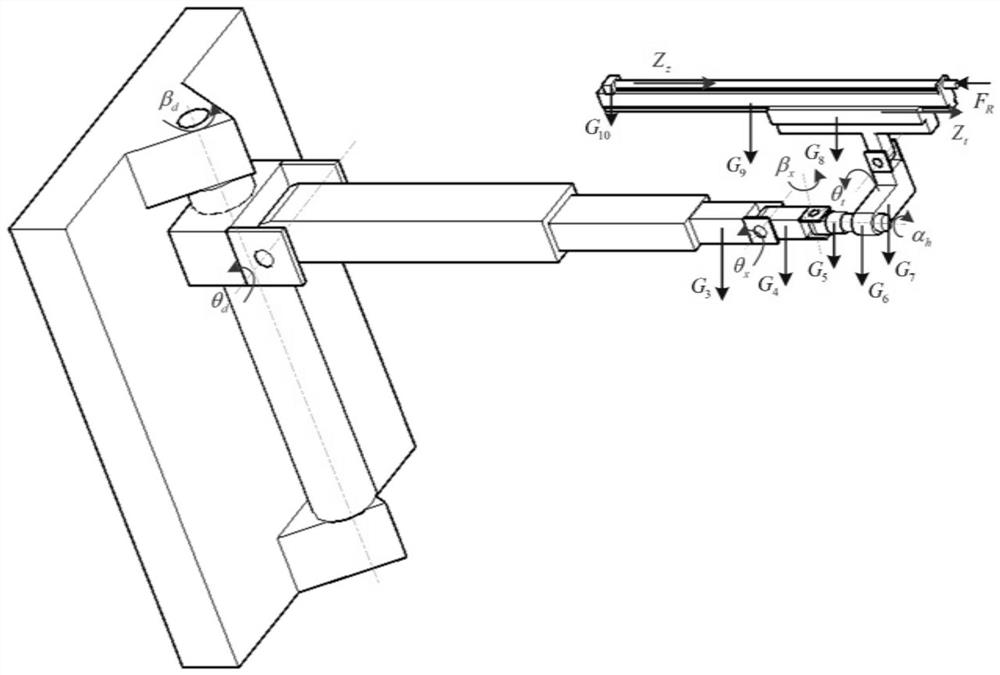

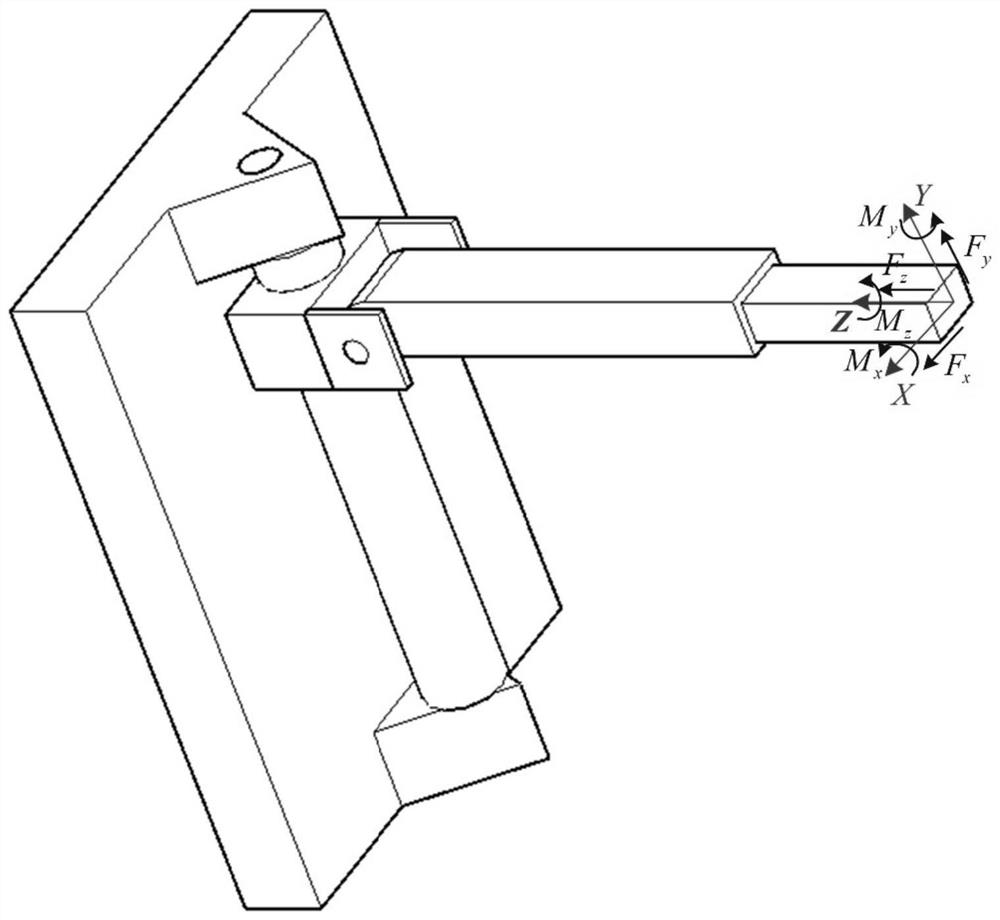

[0064] Specific implementation mode 1. Combination Figure 1 to Figure 7 As shown, the present invention provides a method for calculating the limit working conditions of the telescopic arm of the rock drilling rig, including:

[0065] Step 1: Calculate and obtain the gravity and center of gravity of each component in the telescopic boom structure of the rock drilling rig through computer-aided design software, and determine the rock recoil load and the respective freedom of the boom structure according to the assembly and connection relationship of each component. degree of variation range;

[0066] Step 2: According to the translation and simplification theorem of the pose transformation matrix and the space force system, the gravity of each component and the rock recoil load received are simplified to the top of the telescopic boom to obtain a load calculation model at the top of the telescopic boom;

[0067] Step 3: Use the degrees of freedom of the jib structure as the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com