Multi-oil-cavity dynamic and static pressure sliding bearing oil film characteristic simulation method based on high-order isogeometry

A technology of sliding bearings and simulation methods, which is applied in the field of dynamic and static pressure bearings, can solve problems such as high calculation costs, difficult solution methods, and non-optimal solutions, and achieve the effects of efficient and accurate solution process, improved calculation efficiency, and improved calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

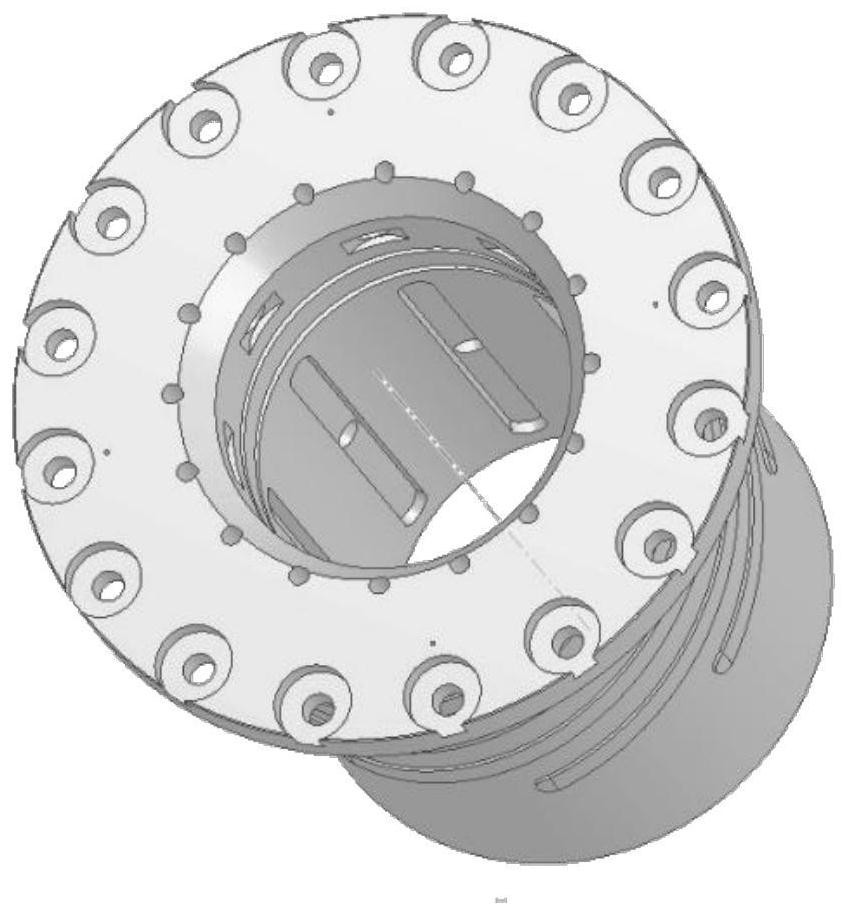

[0072] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The method of the present invention can be used to solve the oil film pressure distribution of various internal feedback dynamic and static pressure sliding bearings with complex structures. This embodiment adopts a certain type of high-power fast reactor radial internal feedback dynamic and static pressure bearings, such as figure 1 As shown, this type of fast reactor radial inner feedback dynamic and static pressure bearing has a diameter of 450mm, a total width of 750mm, a unilateral gap of 0.3mm, a feedback cavity wrap angle of 20°, a feedback cavity width of 40mm, a working cavity wrap angle of 11.5°, and a working cavity width of 253mm, rotational speed 10000rpm, eccentricity 0.7, lubricant viscosity 0.01Pa·s.

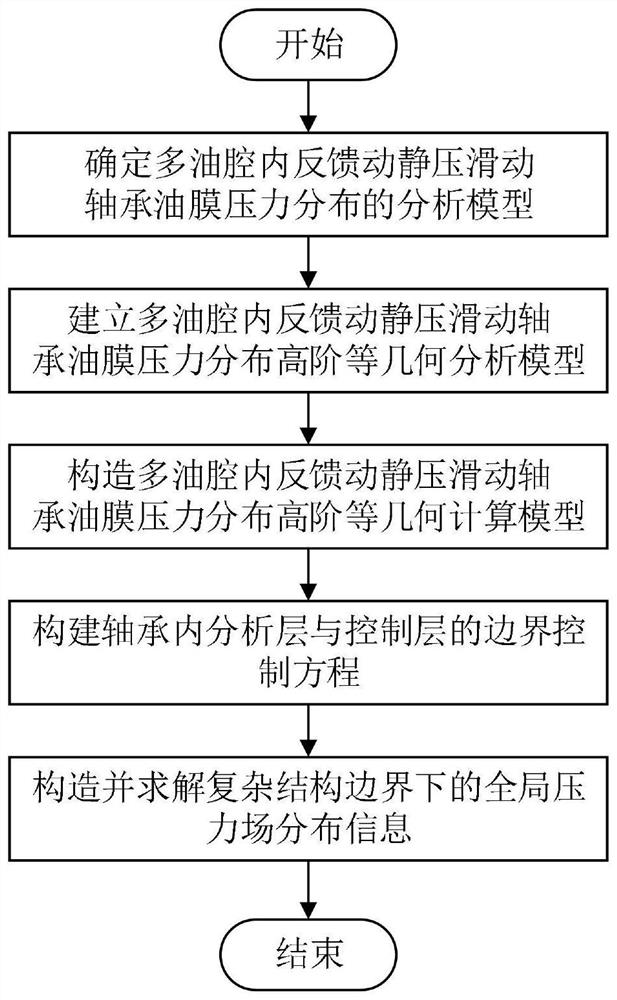

[0073] refer to figure 2 , a simulation method for the oil film characteristics of multi-cavity hydrostatic and hydrostatic sliding bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com