Method for predicting interlayer thermal stress distribution in selective laser melting process based on COMSOL

A technology of selective laser melting and thermal stress, which can be used in design optimization/simulation, process efficiency improvement, special data processing applications, etc., and can solve problems such as inability to accurately predict thermal stress distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

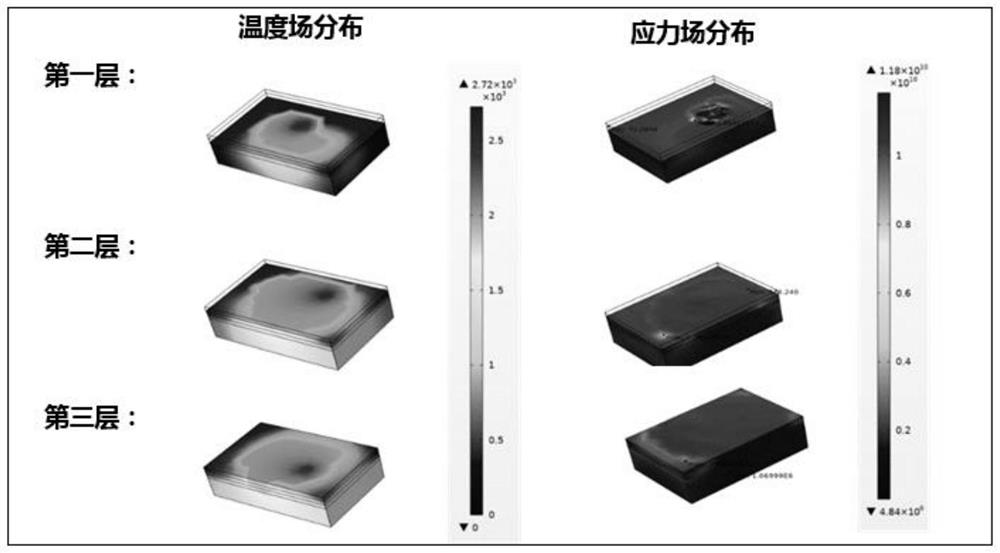

[0031] Below in conjunction with accompanying drawing, the present invention is further described:

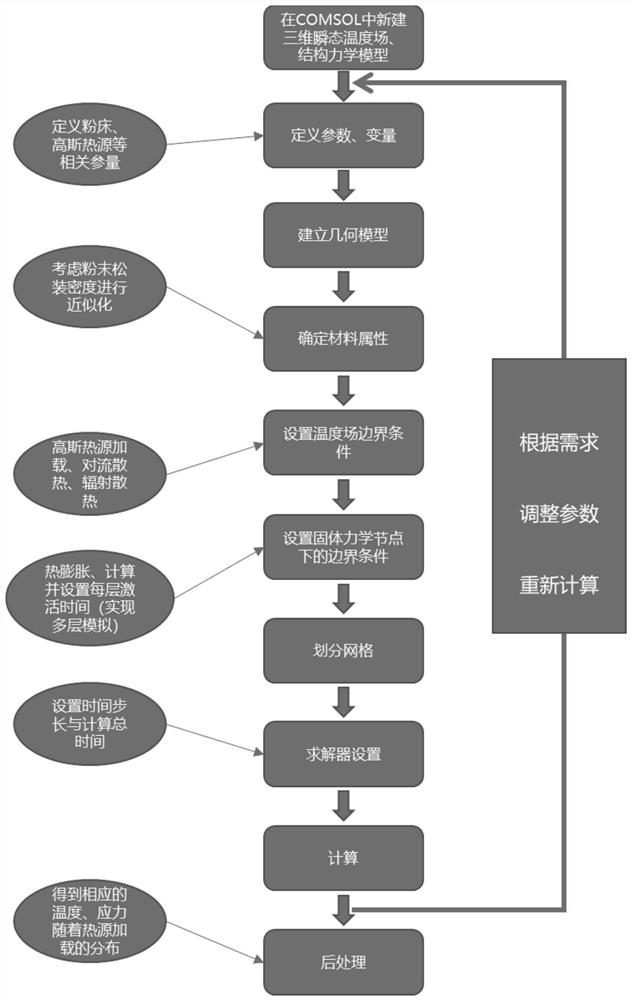

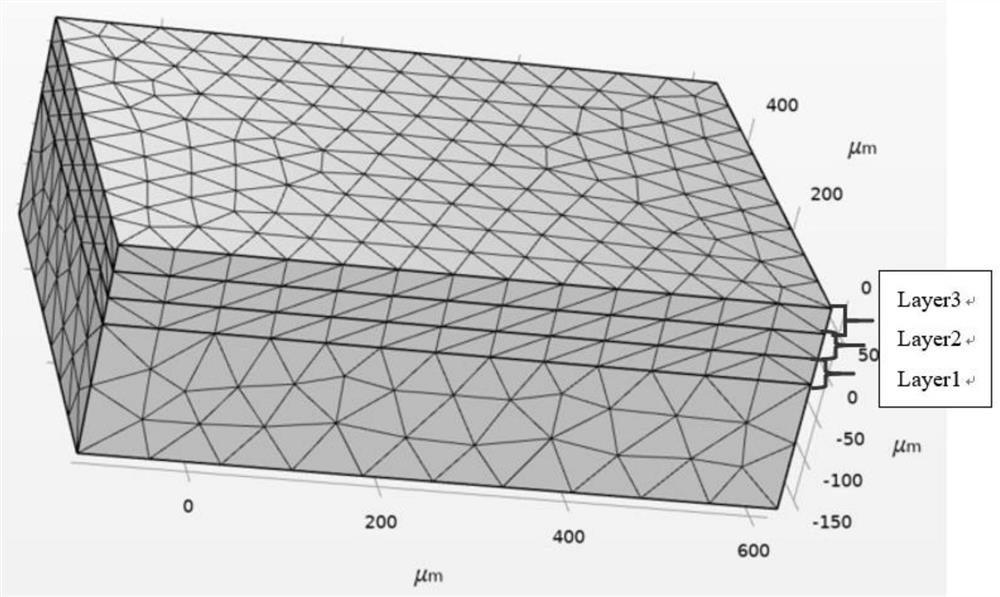

[0032] The present invention provides a method based on COMSOL to predict the interlayer thermal stress distribution in the selective laser melting process, characterized in that: the method includes the following steps: figure 1 as shown,

[0033] S1: Build a 3D solid heat transfer and structural mechanics transient model based on COMSOL;

[0034] S2: Determine the parameters in the simulation process, the parameters include scanning interval D_spot, laser scanning speed v_spot, laser power P_laser, laser radius r_spot, surface radiation rate A_Gass, powder accumulation rate w_powder and powder layer thickness;

[0035] S3: Determine the material properties of the powder to be melted, the material properties include thermal conductivity, specific heat capacity, material density, thermal expansion coefficient, Young's modulus and Poisson's ratio;

[0036] S4: Determine the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com