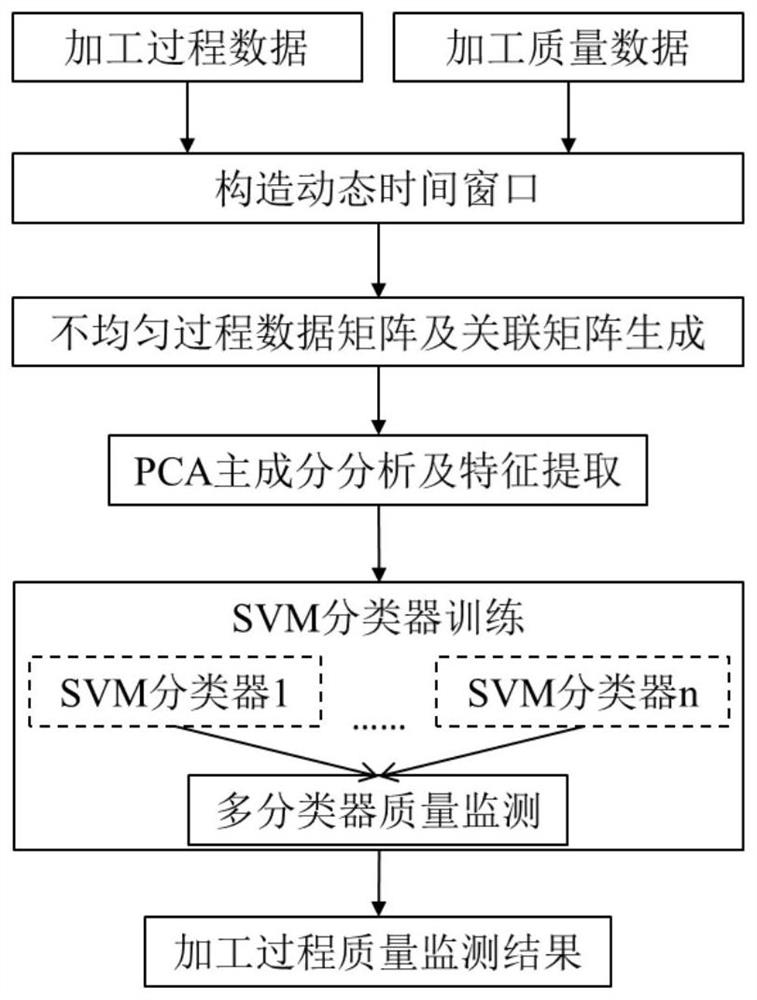

Processing quality monitoring method based on dynamic PCA-SVM

A PCA-SVM and processing quality technology, applied in the field of mechanical processing, can solve the problems of poor quality analysis and monitoring accuracy, low efficiency, and difficulty in extracting time-series dynamic relationships in complex dynamic processing processes, so as to improve accuracy and calculation efficiency, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] In order to overcome the problem of poor accuracy and low efficiency of the existing processing quality monitoring method for complex product processing quality monitoring with dynamic and time-series correlations, the present invention proposes a method suitable for irregular sampling of processing data and processing quality data in the processing process. , and a process quality monitoring method with time series correlation.

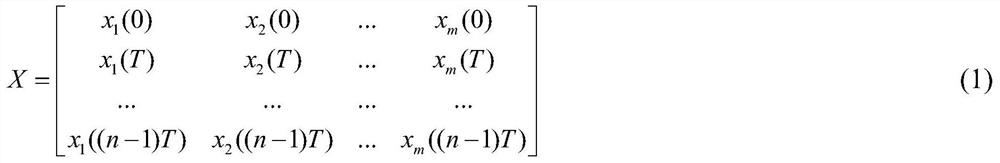

[0034] Step 1: Express the processing data and uneven quality data as follows:

[0035]

[0036]

[0037] where X∈R n×m Represents n sample processing data matrix containing m processing variables, Y un ∈R n ×p Indicates a non-uniform quality data matrix containing p processing quality variables, n y Indicates the number of samples of quality variables; T indicates the sampling period of processing data;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com