Method for stripping purple phosphorus nanosheet by laser

A laser lift-off and nanosheet technology, applied in chemical instruments and methods, phosphorus, phosphorus compounds, etc., can solve the problems of difficult removal of organic solvents, low yield and small size, and achieve safe preparation process, large output, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

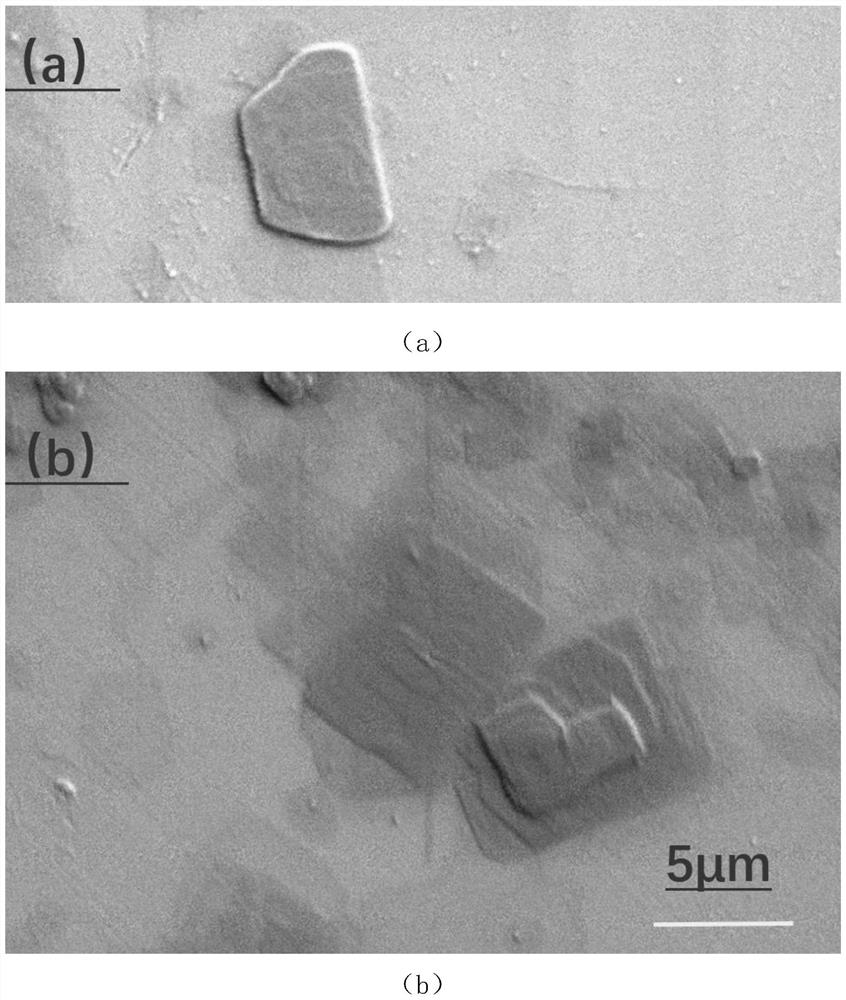

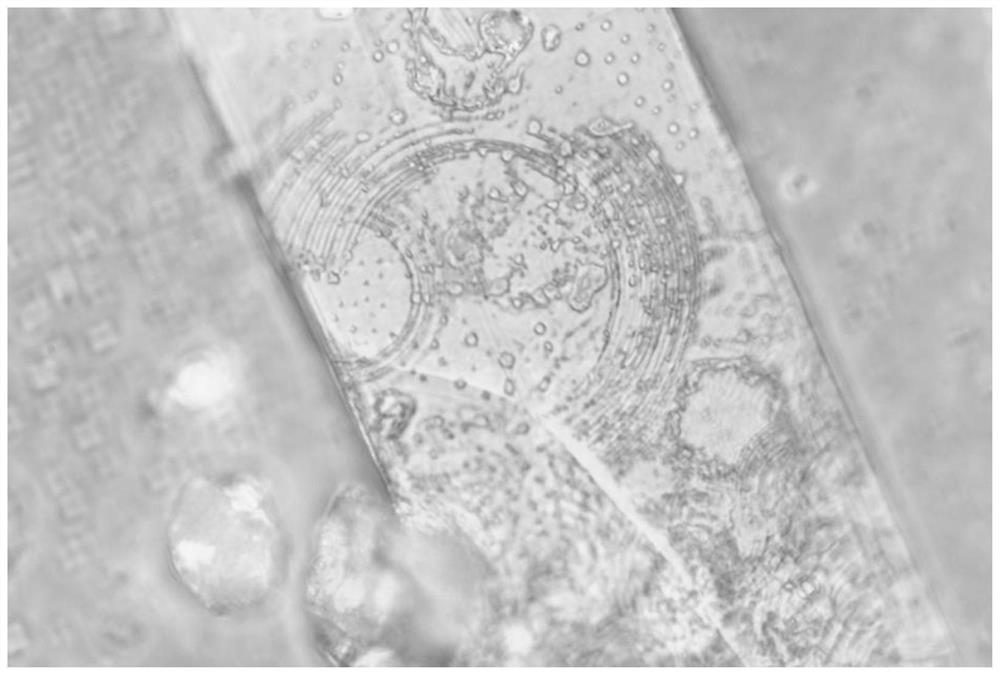

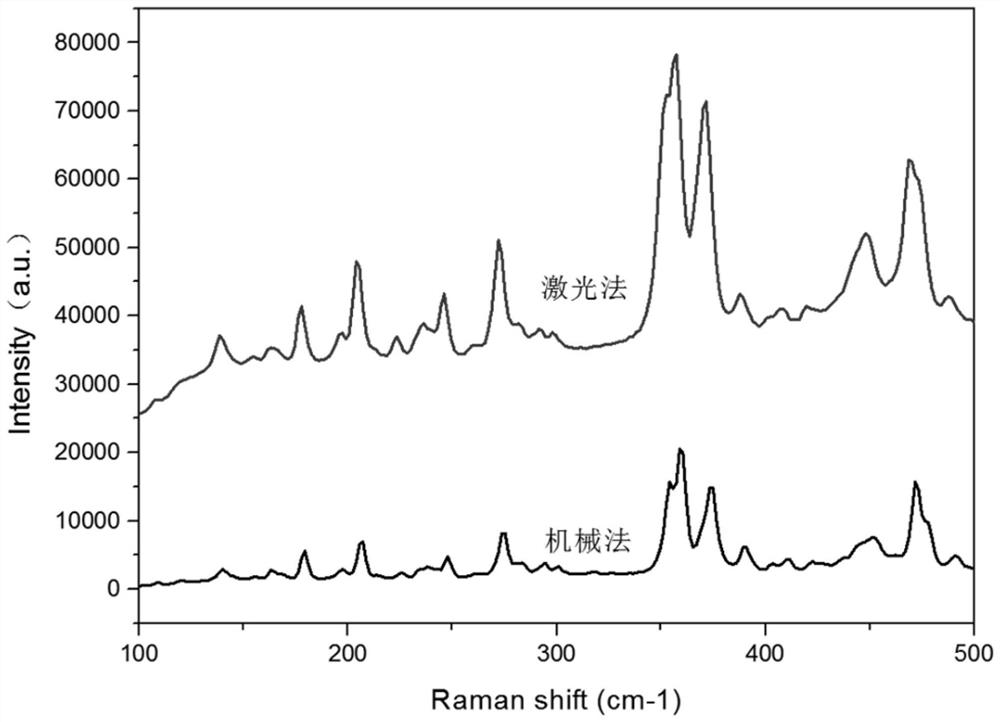

Image

Examples

Embodiment 1

[0057] Using 1070nm infrared continuous laser to strip purple phosphorus, the specific preparation steps are as follows:

[0058] (1) Preliminary preparation

[0059] Put purple phosphorus in a glass tube and add 1ml of isopropanol solution with a concentration of 13.5mol / L.

[0060] (2) Purple phosphorus stripping

[0061] Draw the laser irradiation area and movement path, the parameters are as follows: scanning speed 100mm / s, repetition times 1 time, laser power 8000W. Place the glass tube containing the sample in the operating platform for laser irradiation.

[0062] In an argon atmosphere at normal temperature and pressure, the temperature was controlled at 40°C and dried for 12 hours. After laser irradiation, the color of the solution changed from colorless to slightly yellow, which proved that the laser bombarded the surface of purple phosphorus to prepare small-sized purple phosphorus.

Embodiment 2

[0064] Using 1080nm infrared continuous laser to strip purple phosphorus, the specific preparation steps are as follows:

[0065] (1) Preliminary preparation

[0066] Put purple phosphorus in a glass tube and add 50ml of propanol solution with a concentration of 8mol / L.

[0067] (2) Purple phosphorus stripping

[0068] Draw the laser irradiation area and movement path, the parameters are as follows: scanning speed 10mm / s, repetition times 30 times, laser power 2000W. Place the glass tube containing the sample in the operating platform for laser irradiation.

[0069] In an argon atmosphere at normal temperature and pressure, the temperature was controlled at 60°C and dried for 8 hours. After laser irradiation, the color of the solution changed from colorless to slightly yellow, which proved that the laser bombarded the surface of purple phosphorus to prepare small-sized purple phosphorus.

Embodiment 3

[0071] Violet phosphorus was stripped by 1070nm infrared continuous laser. Concrete preparation steps are as follows:

[0072] (1) Preliminary preparation

[0073] Put purple phosphorus in a glass tube, add 100ml deionized water.

[0074] (2) Purple phosphorus stripping

[0075] Draw the laser irradiation area and movement path, the parameters are as follows: scanning speed 3mm / s, repetition times 20 times, laser power 3000W. Place the glass tube containing the sample in the operating platform for laser irradiation.

[0076] In an argon atmosphere at normal temperature and pressure, the temperature was controlled at 80°C and dried for 4 hours. After laser irradiation, small particles precipitated at the bottom of the solution, which proved that the laser bombarded the surface of purple phosphorus to prepare small-sized purple phosphorus but easy to agglomerate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com