Boiler heating surface soot blowing control system and control method

A control system and control method technology, applied in the field of boilers, can solve problems such as wear and erosion of heating surface furnace tubes, consumption of high-temperature steam, and consumption of soot-blowing working fluid, so as to achieve accurate and visualized soot blowing, improve soot blowing effect, and slow down Effect of Thin Velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

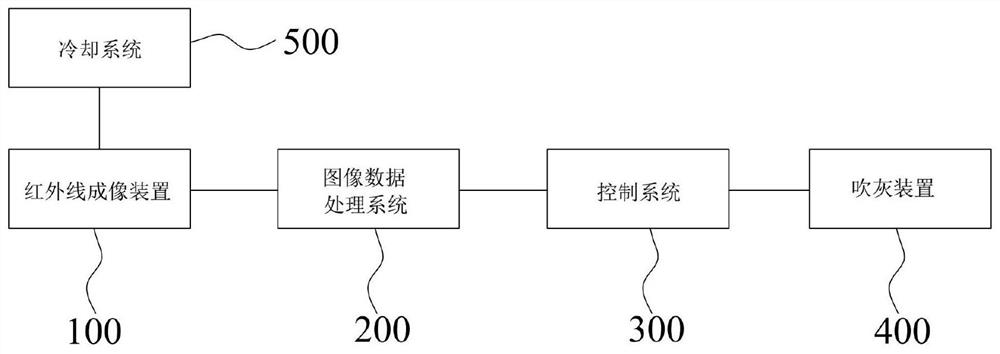

[0028] Such as figure 1 As shown, this embodiment provides a boiler heating surface soot blowing control system, including an infrared imaging device 100, an image data processing system 200, a control system 300 and a soot blowing device 400, wherein the infrared imaging device 100 can absorb the wavelength and output the thermal imaging of the heating surface, the image data processing system 200 is connected with the infrared imaging device 100, the control system 300 is connected with the image data processing system 200, the image data processing system 200 processes the signal sent by the infrared imaging device 100, and Send the processed temperature data of the heating surface to the control system 300, which is connected to the soot blowing device 400. When the temperature of the heating surface is higher than the first preset temperature, the control system 300 controls the soot blowing device 400 to blow soot.

[0029] The boiler heating surface soot blowing control...

Embodiment 2

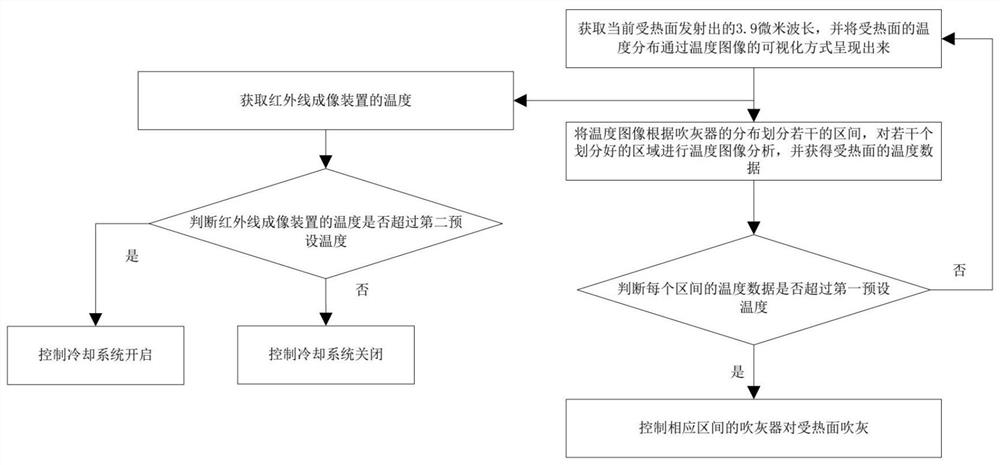

[0037] Such as figure 2 As shown, this embodiment provides a method for controlling soot blowing on the heating surface of a boiler, comprising the following steps:

[0038] Obtain the 3.9 micron wavelength emitted by the current heating surface, and present the temperature distribution of the heating surface through the visualization of temperature images;

[0039] Divide the temperature image into several intervals according to the distribution of the soot blowers, analyze the temperature image of several divided areas, and obtain the temperature data of the heating surface;

[0040] Determine whether the temperature data in each section exceeds the first preset temperature, if it exceeds the first preset temperature, control the sootblower in the corresponding section to blow soot on the heating surface; if it does not exceed the first preset temperature, repeat the above steps .

[0041] Among them, the infrared imaging device 100 can be used to obtain the wavelength; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com