Multi-fano resonance metasurface refractive index sensor based on rectangular ring hole

A technology of refractive index sensor and metasurface, which is applied in the direction of instruments, scientific instruments, phase influence characteristic measurement, etc., can solve the problems of low Q value of metal structure, strong radiation loss, etc., and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention is explained in detail below in conjunction with accompanying drawing: This implementation example is based on the premise of a kind of multi-fano resonance metasurface refractive index sensor based on rectangular ring holes proposed by the present invention. It should be known that the protection scope of the present invention includes but not only limited to this instance.

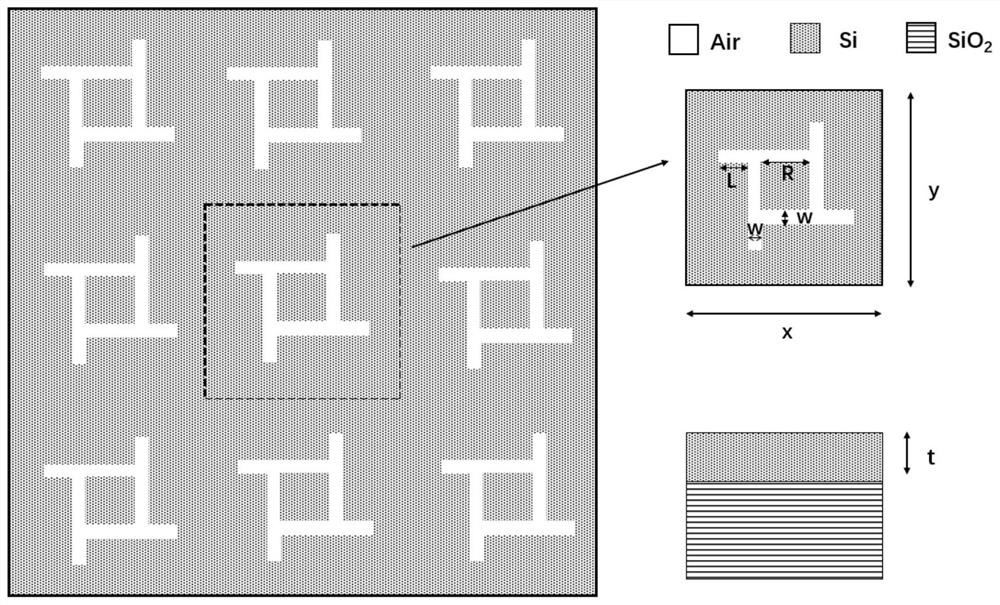

[0022] figure 1 An example of a multi-fano resonant metasurface refractive index sensor based on rectangular ring holes is listed, including metasurface structures and transparent silicon dioxide structure substrates. This example consists of several microstructure units, and a rectangular ring hole connecting rectangular short cavity holes is etched in each dielectric metasurface microunit. Among them, the inner side lengths of the rectangular rings are equal, R=250nm, which is a square ring structure, the ring width is w=60nm, the width of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com