Refractive index sensor based on high quality factor all-dielectric super surface and application

A refractive index sensor and high quality factor technology, applied in the field of optical sensing, can solve the problems of metal biotoxicity, low degree of control freedom, unfavorable metal structure, etc., and achieve the effect of short action distance and no ohmic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings: the case of this embodiment is based on a refractive index sensor system based on a high-quality factor all-dielectric metasurface proposed by the present invention, but the scope of protection of the present invention is not limited to The following implementation modes and cases.

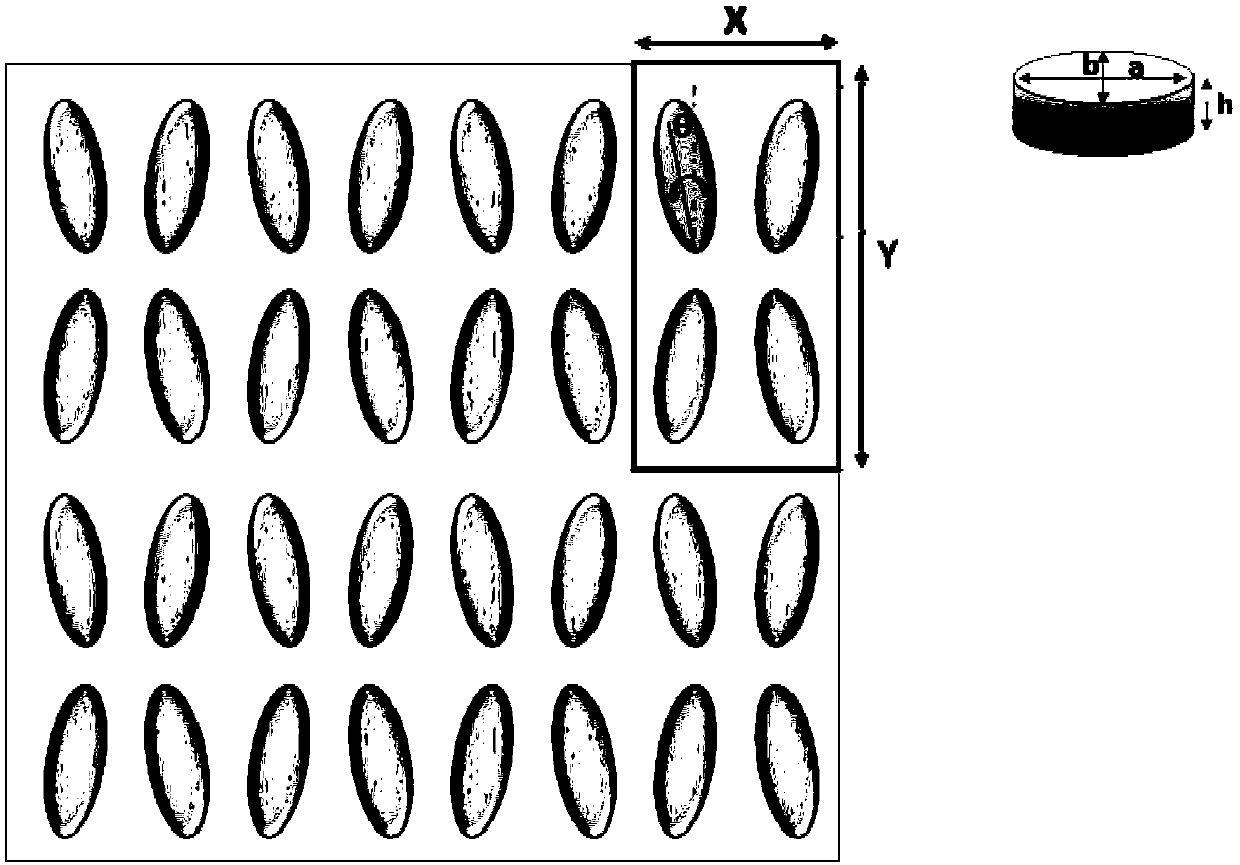

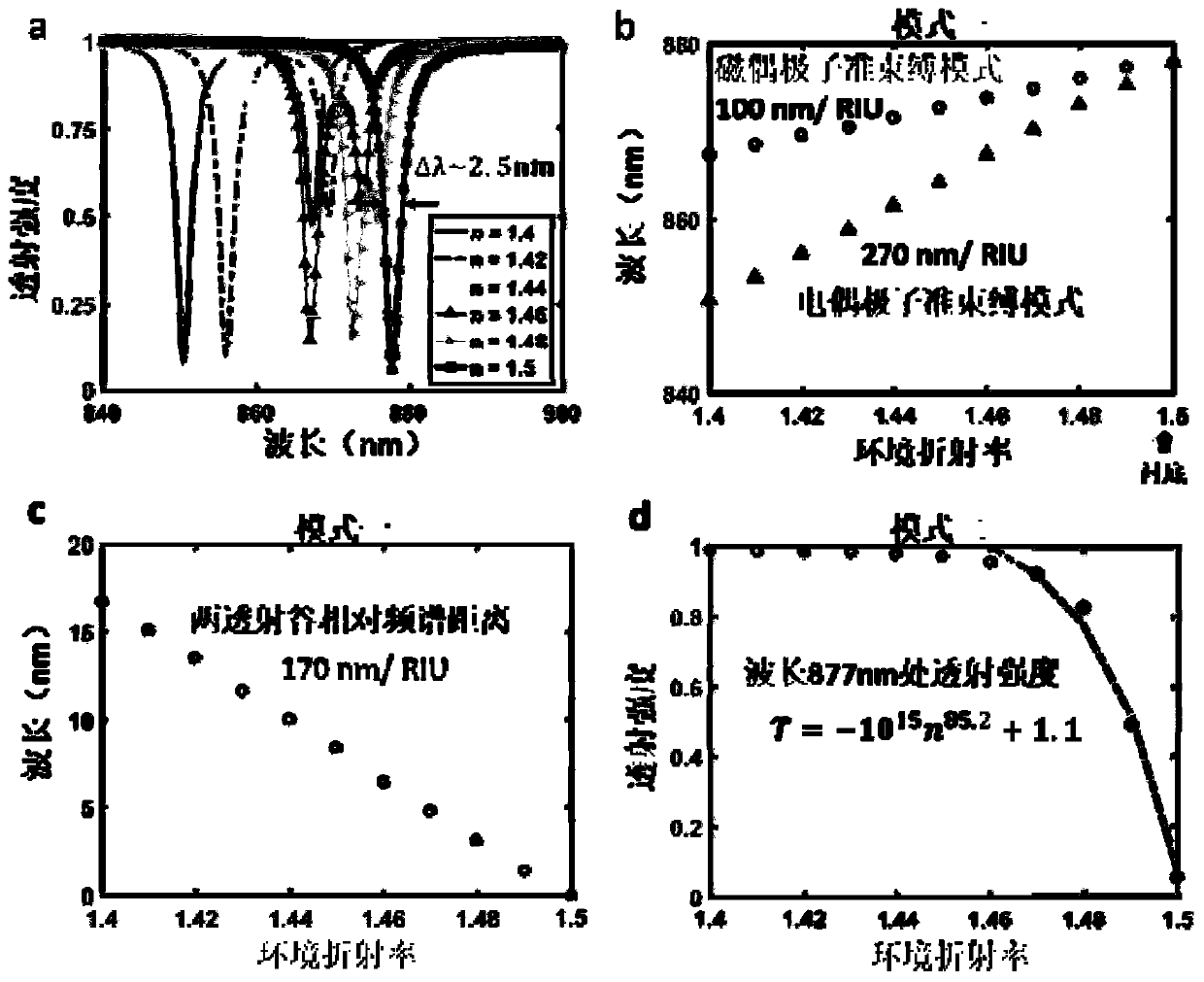

[0028] Such as figure 1 As shown, a refractive index sensor system based on a high-quality factor all-dielectric metasurface includes an optical device with a metasurface structure and a transparent substrate. The two-dimensional elliptical disc array is located on a transparent substrate, the material is crystalline silicon, and the Y-direction period is 720nm, the X-direction period is 620nm, the major axis diameter of the elliptical disc structure is a=300nm, the minor axis diameter is b=110nm, and the height It is h=180nm, the major axis is along the Y a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Major axis diameter | aaaaa | aaaaa |

| Minor axis diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com