CO2 monitoring system for suffocation case

A monitoring system, CO2 technology, applied in general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problems of intelligence, low degree of automation, unstable concentration of suffocation pit, etc. To ensure the quality of meat and improve the efficiency of slaughtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

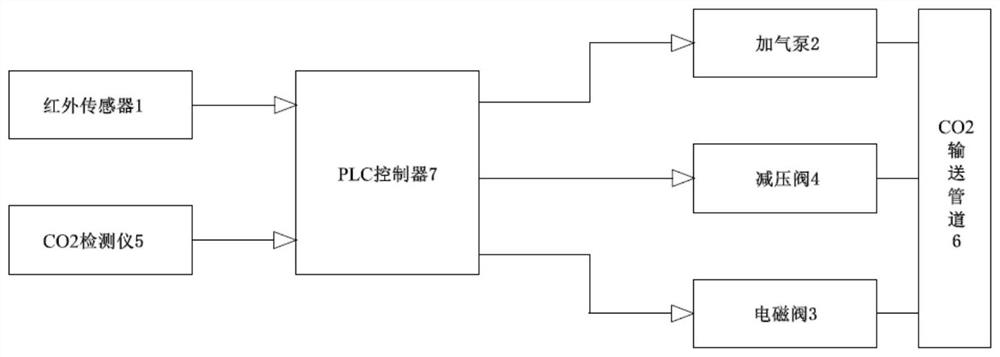

[0025] Implementation mode 1: if figure 1 As shown, the CO2 monitoring system of the stun case includes an infrared sensor 1, an air pump 2, a solenoid valve 3, a pressure reducing valve 4, a CO 2 Detector 5, CO 2 Delivery pipeline 6, PLC controller 7, the infrared sensor 1, air pump 2, solenoid valve 3, pressure reducing valve 4, CO 2 Detector 5, CO 2 The conveying pipelines 6 are all electrically connected to the PLC controller 7, wherein the infrared sensor 1 is arranged in the suffocation pit for detecting CO in the suffocation pit. 2 concentration; the gas pump 2 is set at CO 2 The inlet end of the delivery pipeline 6 is used to supply CO 2 Delivery pipeline 6 is pumped into CO for asphyxiation 2 ; The solenoid valve 3 is set at CO 2 The gas outlet end of the delivery pipeline 6 is used to convert CO 2 CO for asphyxiation in delivery pipeline 6 2 into the suffocation pit; the pressure relief valve 4 is arranged on the CO at the upstream end of the electromagnetic ...

Embodiment approach 2

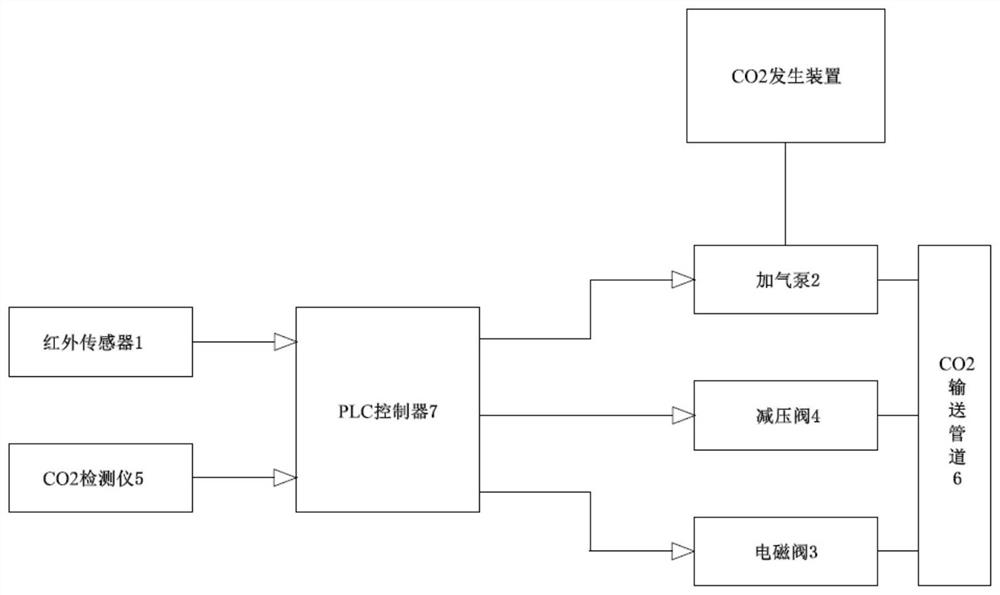

[0026] Implementation mode 2: if figure 2 shown, to achieve CO 2 Occurrence supply, this stun chassis CO 2 The air pump 2 in the monitoring system is externally connected to a CO 2 generating device. In order to realize the supply into CO 2 The concentration adjustment of the conveying pipeline, the CO 2 monitoring system for the CO 2 The generating device is connected with the output end of the PLC controller 7 . The rest of the structures and components are the same as those in Embodiment 1 and will not be described again.

Embodiment approach 3

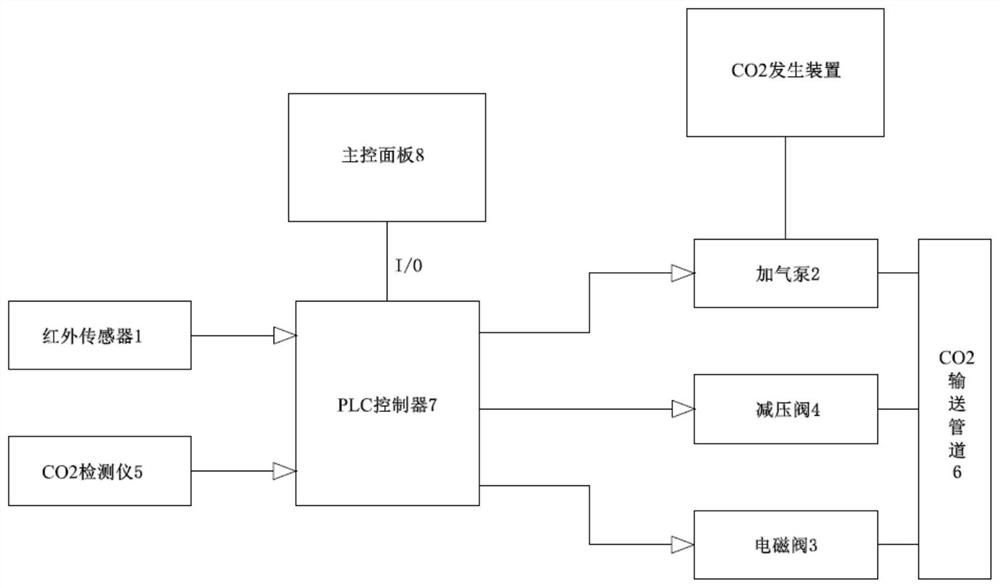

[0027] Implementation mode 3: if image 3 As shown, in order to realize the external asphyxiation pit, CO 2 CO in the pipeline 2 Concentration monitoring data display, manual intervention control, and modification of PLC prefabricated programs, the CO 2The PLC controller 7 of the monitoring system is connected to a main control panel 8 through an I / O interface, and the main control panel 8 includes a display screen, control buttons and an editing keyboard. The rest of the structures and components are the same as those in Embodiment 1 and will not be described again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com