Method for monitoring carrier concentration of SiGe structure

A technology of carrier concentration and concentration, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effects of improving monitoring frequency, high-frequency production line stability monitoring, and efficient monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

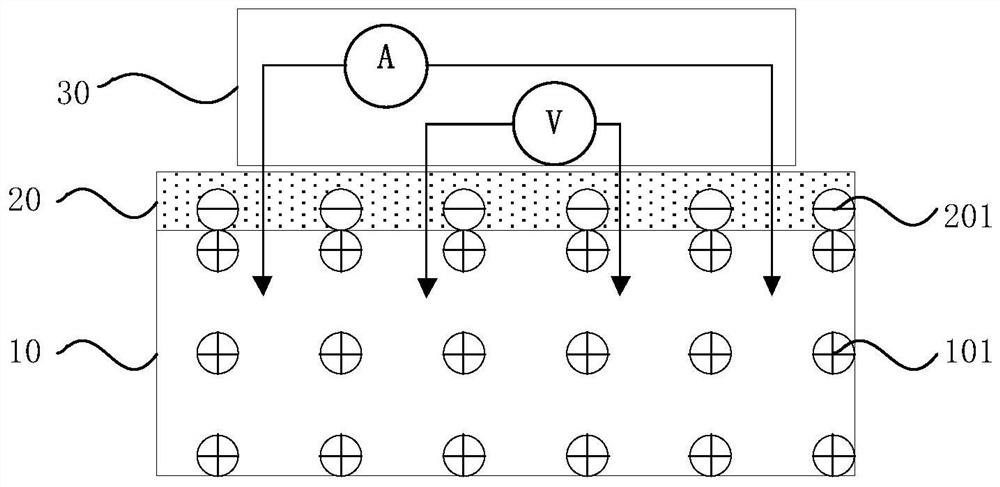

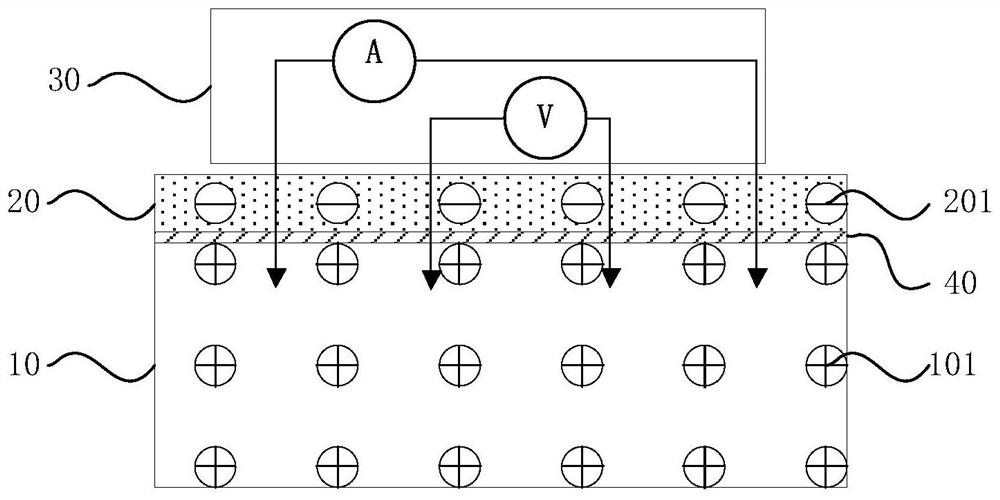

[0036] figure 1 Four Probe is a schematic diagram of a prior art SiGe structures. like figure 1 Shown, when using four-point probe tester 30 'of SiGe structures 10' of the resistivity testing, test results unstable, and there is a trend (latency) increased gradually with prolonged Q-time. And the inventors have found that instability results from the test wafer after removal of the monitoring machine growth, and gradually exposed to natural oxidation caused by air and the surface silicon atoms after the contact. Specifically, i.e. native oxide layer is SiGe 10 'hole carrier surface 101' formed on its surface structure 20 'dangling bonds charge 201' formed complex trapped charge, leading to increased resistivity, conductivity drops .

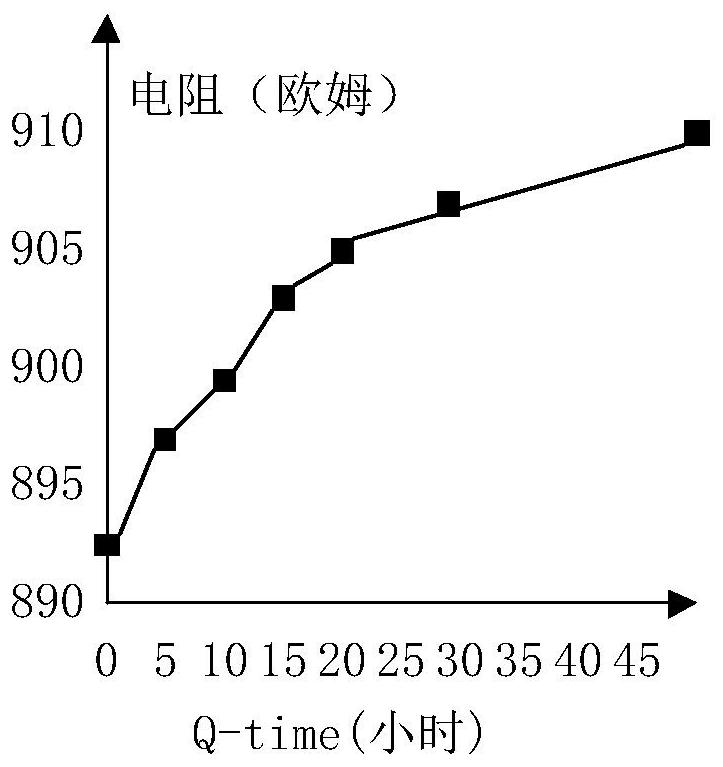

[0037] Meanwhile, data from the study of the inventors (e.g. figure 2 ) Found that a natural oxide 'has a very serious negative impact resistance test, SiGe structures 10' of the electrical resistivity SiGe structures 10 to almost linearly increased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com