Method and system for reducing vessel fuel consumption

A fuel consumption, ship technology, applied in waterborne ship navigation equipment, hull design, transportation and packaging, etc., can solve problems such as slowing down the speed of the ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

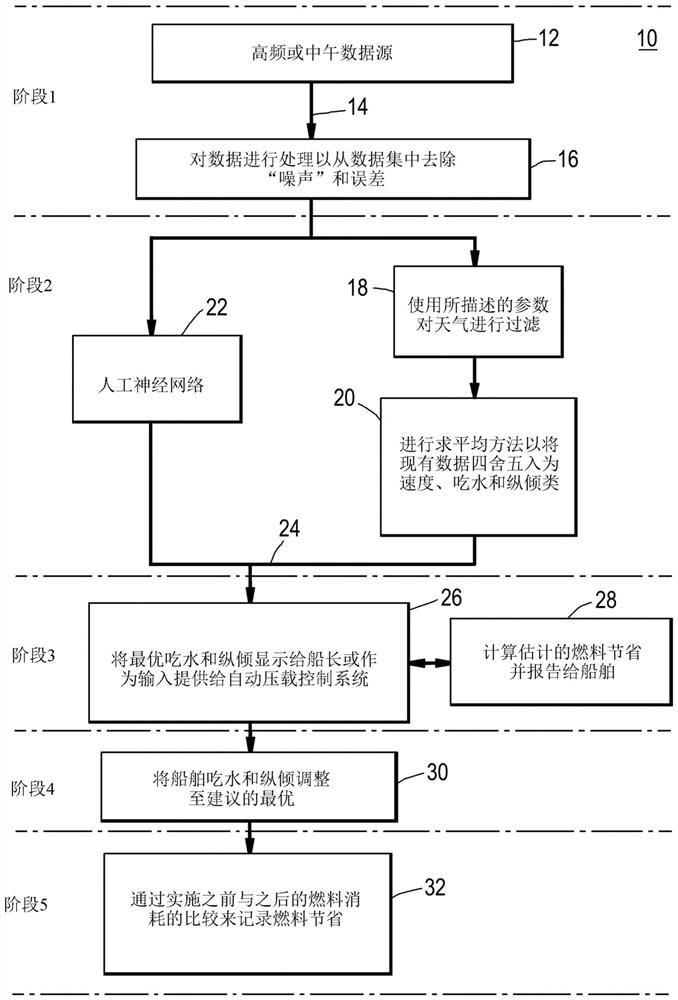

Embodiment Construction

[0040] Certain terms used herein are defined as follows:

[0041] "LNG" means liquefied natural gas, which is generally cooled to at least a temperature at which the gas can assume a liquid phase at a pressure of about 1 bar; for liquefied methane, this temperature is about minus 162°C;

[0042] "Draft" may refer to the depth of water required to float a vessel; the depth below the waterline to the bottom of the hull of the vessel; and the depth of water drawn by the vessel. In this disclosure, "draft" may specifically refer to the depth below the waterline to the bottom of the hull of a vessel; and

[0043] "Trim" refers to the position of the ship relative to the horizontal; in other words, "trim" refers to the difference between the draft at the fore end of the ship and the draft at the aft end.

[0044] Whenever a ship is sailing at a given speed, whether carrying cargo or under ballast, the optimum trim and draft conditions for said ship exist. For ships in service, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com