Hazardous chemical substance management cabinet and weighing method

A technology for hazardous chemicals and management cabinets, applied in cabinets, adjustable cabinets, household appliances, etc., can solve problems such as injuries, hazards of hazardous chemicals administrators, and differences in the data of hazardous chemicals in and out of the warehouse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

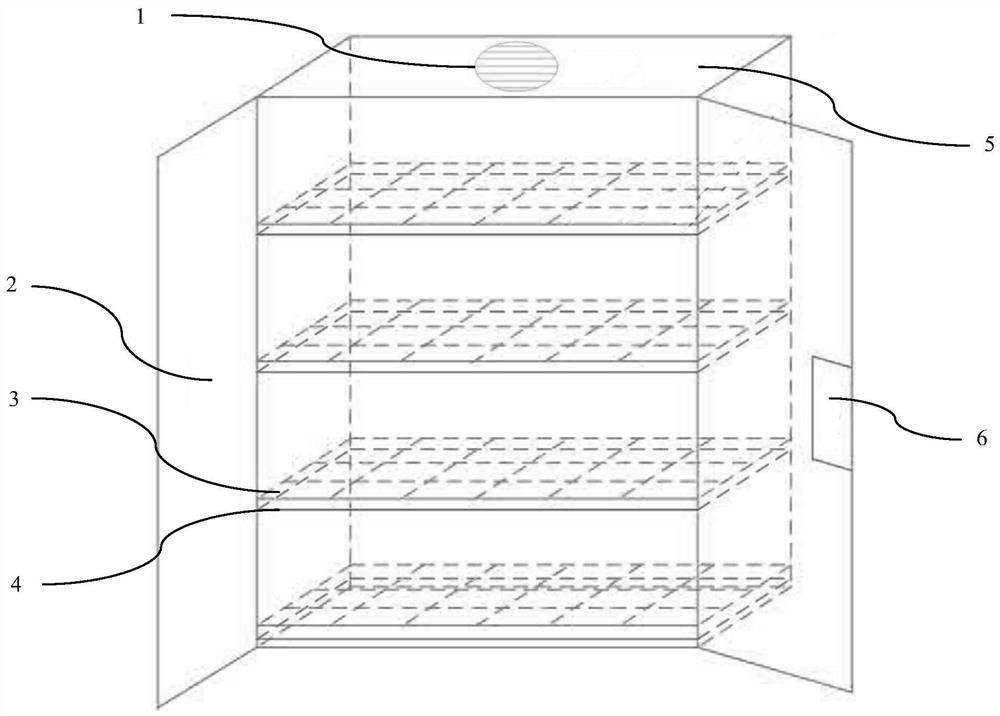

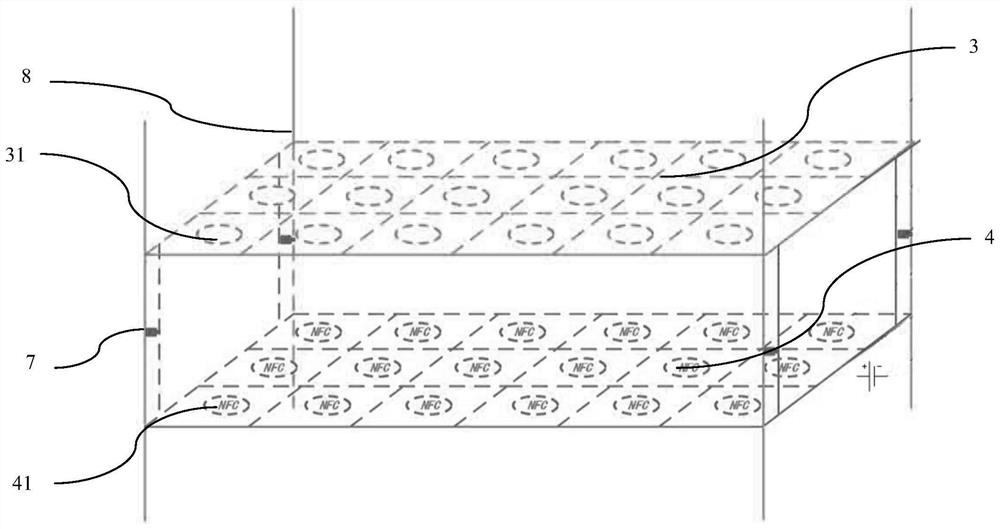

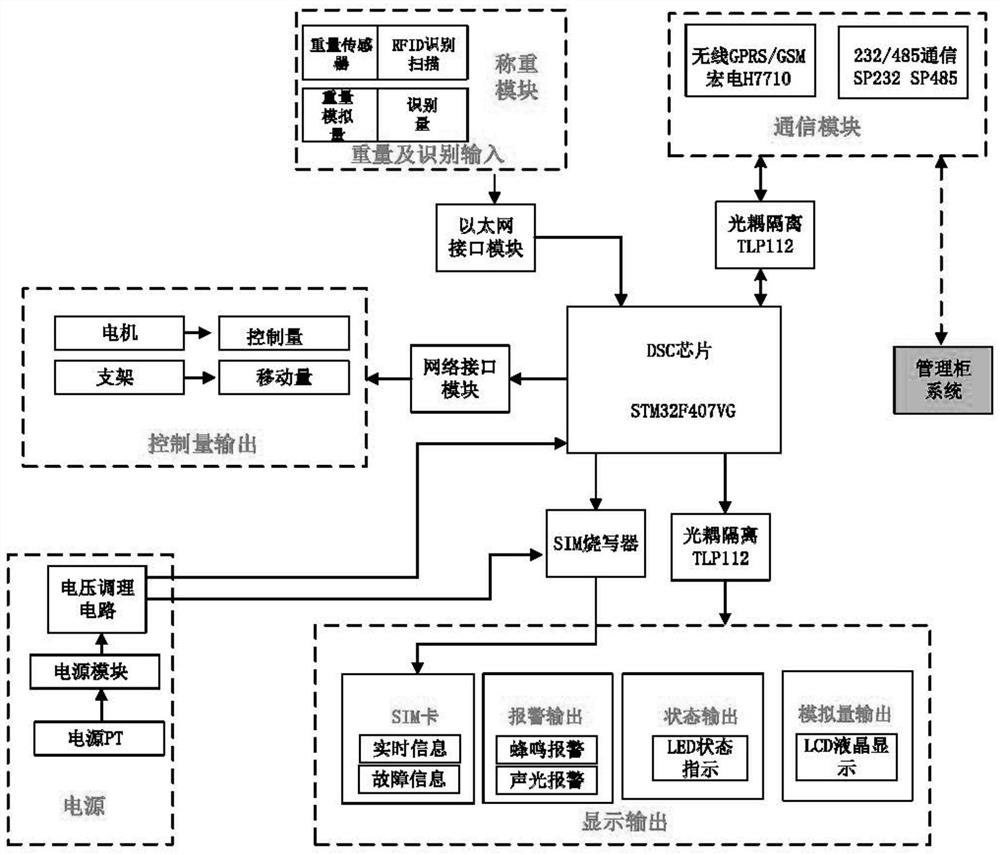

[0027] Such as figure 1 with figure 2 As shown, in this embodiment, the hazardous chemicals management cabinets are set independently, and no network management is performed. The cabinet body of the hazardous chemicals management cabinet is made of stainless steel, and the main body of the cabinet door is made of explosion-proof glass material with shielding function. A 14.1-inch monochrome LCD screen is installed on the upper part of the cabinet body, and an air exhaust port is opened on the top of the cabinet body. A console and its casing are arranged outside the bottom of the cabinet. A display driver module is installed in the console, and a synchronous motor driver chip and a memory card slot are also installed at the same time. The power supply line is led out from the lower corner of the cabinet, and connected to the 220V mains as the main power supply of the hazardous chemicals management cabinet, and a backup power supply is installed at the bottom of the cabinet....

Embodiment 2

[0039]In this embodiment, 8 hazardous chemical management cabinets form a network through RS485, and the upper computer of the 8 hazardous chemical management cabinets in the network is used as the central node to perform star connection. The hardware configuration of each hazardous chemical management cabinet is the same as that in Embodiment 1, and the operation process of entering and exiting the warehouse is the same. However, all the output and storage information of the 8 hazardous chemical management cabinets are uploaded to the host computer through the network, and after being counted and stored in the host computer, the host computer is transmitted to the monitor for display.

Embodiment 3

[0041] In this embodiment, one hazardous chemical management database and the same network of hazardous chemical management cabinets as in the second embodiment are included. After the hazardous chemicals are stored in the management cabinet, they are sent to the database by the RS485 network for storage and safekeeping. The rest of the operating modes are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com