Press-fit type positioning resistance welding machine and using method thereof

A resistance welding and welding machine technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unfavorable use, inability to weld objects in feeding or unloading operations, and inability to adjust the welding seat of the welding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

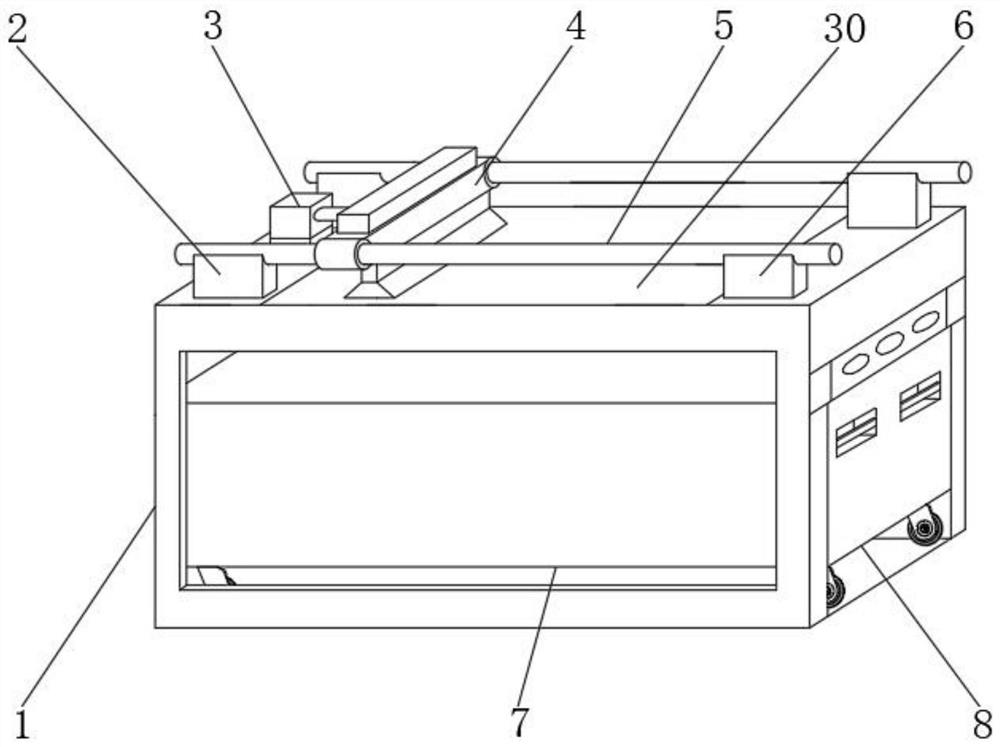

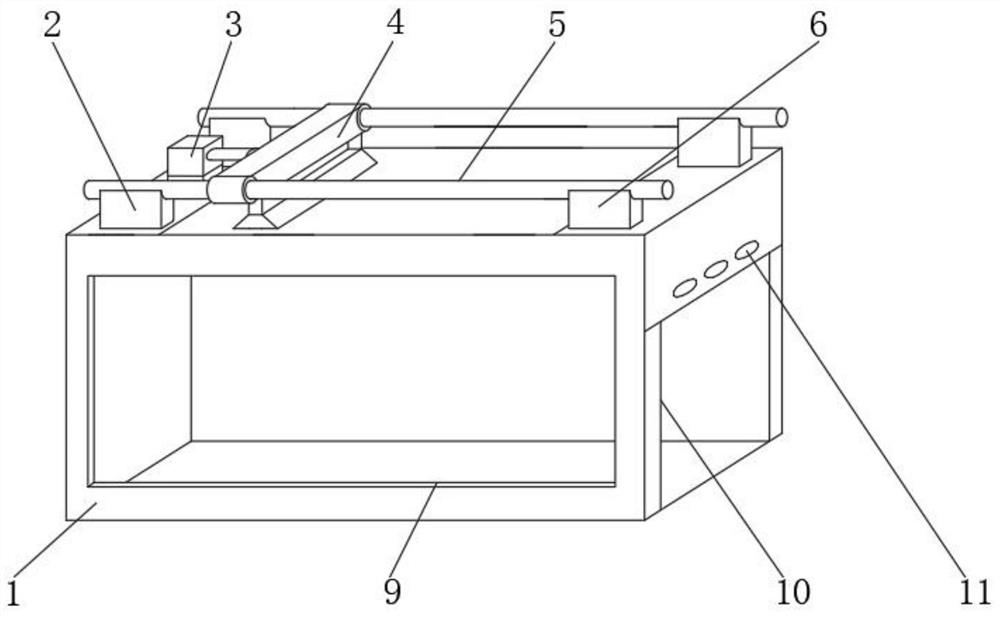

[0032] Such as Figure 1-4 As shown, a press-fit positioning resistance welding machine includes a welding machine main box 1 and a welding mobile car 7, a welding station 30 is provided in the middle of the welding machine main box 1, and a No. 1 positioning block is installed on the upper end of the welding machine main box 1 2. The No. 2 positioning block 6 and the positioning connection seat 23, the positioning rod 5 is installed between the No. 1 positioning block 2 and the No. 2 positioning block 6, and the front end of the welding machine main box 1 is equipped with an observation window 9, and the welding machine main box 1 The inside of the welding machine is provided with a dolly positioning box 10, and a No. magnetic adsorption block 11 is installed on one side of the main box 1 of the welding machine.

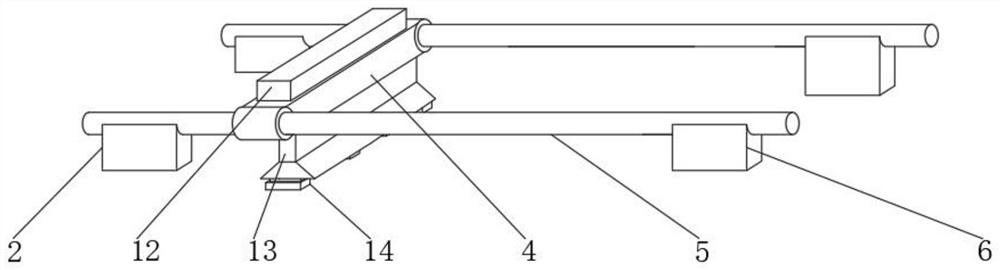

[0033] The outer wall of positioning bar 5 is provided with movable shaft 15, movable frame 4 is installed on the inboard of movable shaft 15, and driving seat 12 i...

Embodiment 2

[0041] On the basis of Example 1, as figure 1 , 5 As shown, a press-fit positioning resistance welding machine includes a welding machine main box 1 and a welding mobile car 7, a welding station 30 is provided in the middle of the welding machine main box 1, and a No. 1 positioning block is installed on the upper end of the welding machine main box 1 2. The No. 2 positioning block 6 and the positioning connection seat 23, the positioning rod 5 is installed between the No. 1 positioning block 2 and the No. 2 positioning block 6, and the front end of the welding machine main box 1 is equipped with an observation window 9, and the welding machine main box 1 The inside of the welding machine is provided with a dolly positioning box 10, and a No. magnetic adsorption block 11 is installed on one side of the main box 1 of the welding machine.

[0042] Both sides of the welding mobile car 7 are provided with slide rails 18, the upper end of the welding mobile car 7 is equipped with a...

Embodiment 3

[0050] On the basis of Example 2, such as figure 1 , 6 As shown, a press-fit positioning resistance welding machine includes a welding machine main box 1 and a welding mobile car 7, a welding station 30 is provided in the middle of the welding machine main box 1, and a No. 1 positioning block is installed on the upper end of the welding machine main box 1 2. The No. 2 positioning block 6 and the positioning connection seat 23, the positioning rod 5 is installed between the No. 1 positioning block 2 and the No. 2 positioning block 6, and the front end of the welding machine main box 1 is equipped with an observation window 9, and the welding machine main box 1 The inside of the welding machine is provided with a dolly positioning box 10, and a No. magnetic adsorption block 11 is installed on one side of the main box 1 of the welding machine.

[0051] The upper end of positioning connection seat 23 is equipped with driving mechanism 3, and a side of driving mechanism 3 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com