Cutting force measuring device

A measuring device and cutting force technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of uncomfortable real-time online monitoring, inconvenient wire power supply, restricting popularization and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

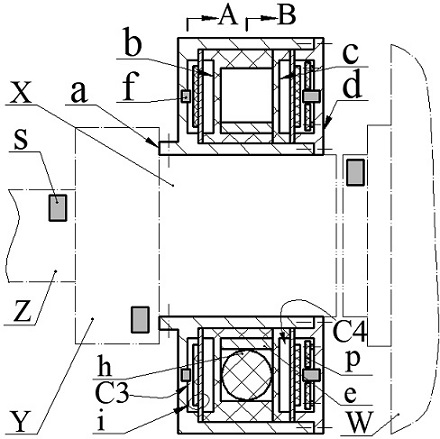

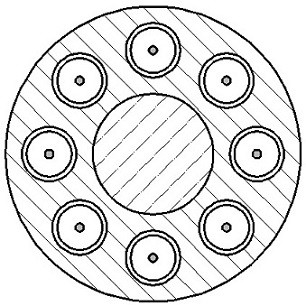

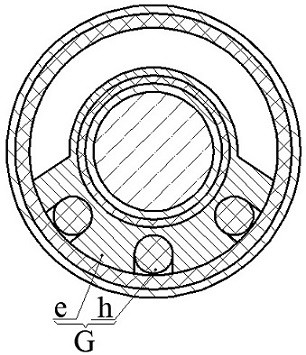

[0032]The present invention proposes a cutting force measuring device, the device is installed on the spindle X of the drilling machine through screws, the end of the spindle X is equipped with a drill bit Z through the fixture Y, and the cutting force measuring device is located between the bed W and the fixture Y; the proposed The cutting force measuring device is mainly composed of casing a, ring frame b, ring plate c, ring cover d, exciter G, limit block f, sensor s, circuit board p and transducer i, casing a, ring The frame b, the ring plate c and the ring cover d are all ring structures; the exciter G is a rolling body h, or is composed of a rolling body h and an inertial body e, and the material of the rolling body h is a magnetic material; the transducer i is composed of a coupling plate i1 and piezoelectric film i2 are bonded, the coupling film i1 is ring-shaped, and the piezoelectric film i2 is circular; the sensor s is installed on the drill bit Z, the fixture Y or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com