Airbag tool fatigue ray nondestructive detection device and automatic detection method thereof

A non-destructive testing and ray technology, used in manufacturing tools, control of workpiece feed movement, metal processing equipment, etc., can solve problems such as fatigue plastic deformation, easy wear, and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

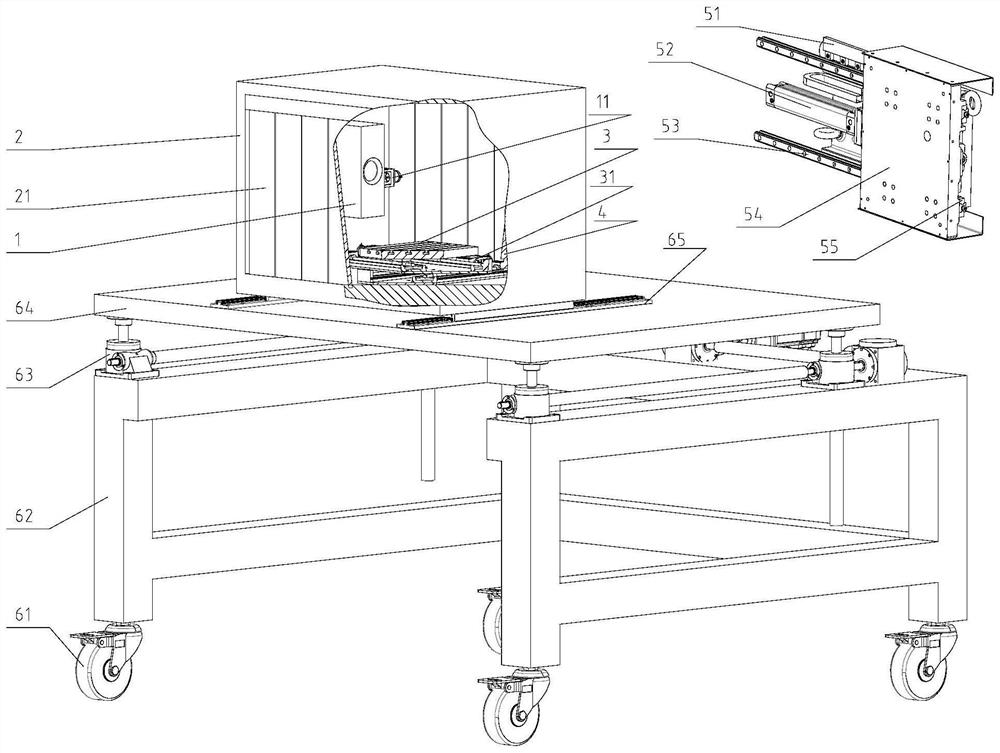

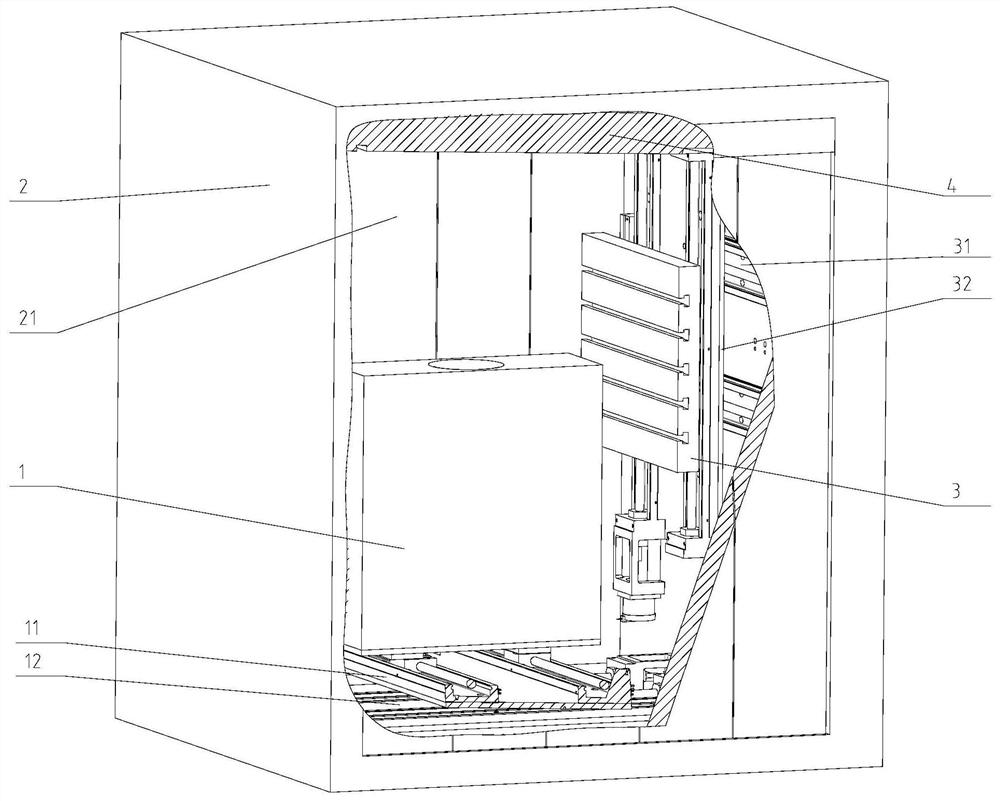

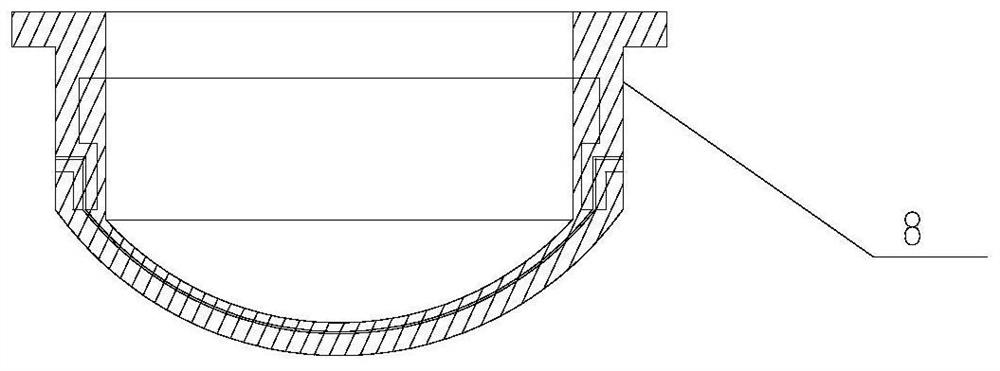

[0032] Such as Figure 1-8 As shown, this embodiment includes three parts: the ray nondestructive testing box, the in-position cylinder guide rail and the mobile lifting frame;

[0033] The ray nondestructive testing box is the core component to complete the detection of the fatigue state of the airbag tool. It can collect the image information of the internal situation of the airbag tool and save the visual image files for a long time. moving parts. The ray non-destructive testing box is connected with the in-position cylinder guide rail or the mobile lifting frame, so as to adjust the airbag tool in the ray range under the two working modes of non-detection or offline detection and obtain the state i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com