Multifunctional screening and dust removing device for modified plastic granulation

A dust removal device and multifunctional technology, which is applied in the field of screening and dust removal devices for multifunctional modified plastic granulation, can solve the problems of affecting the air environment and different particle sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

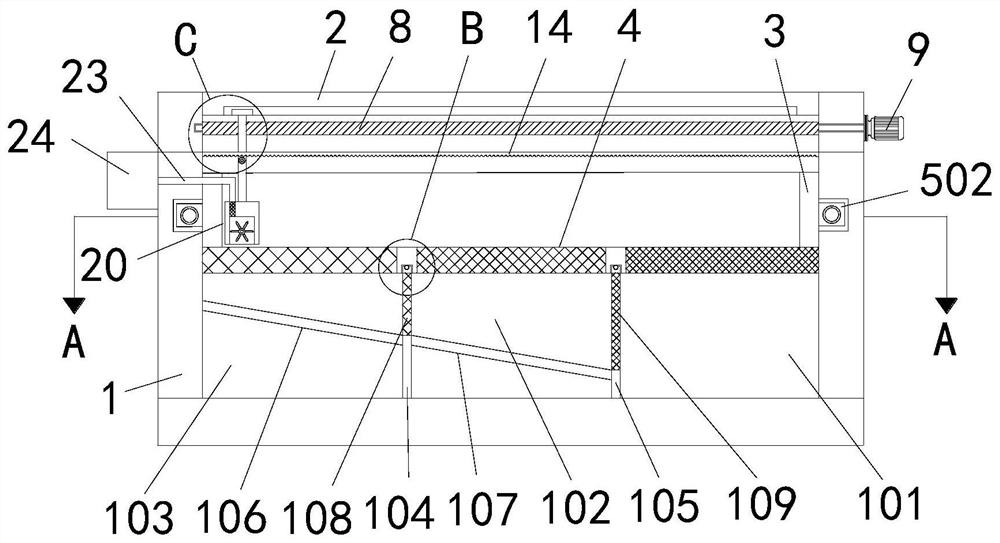

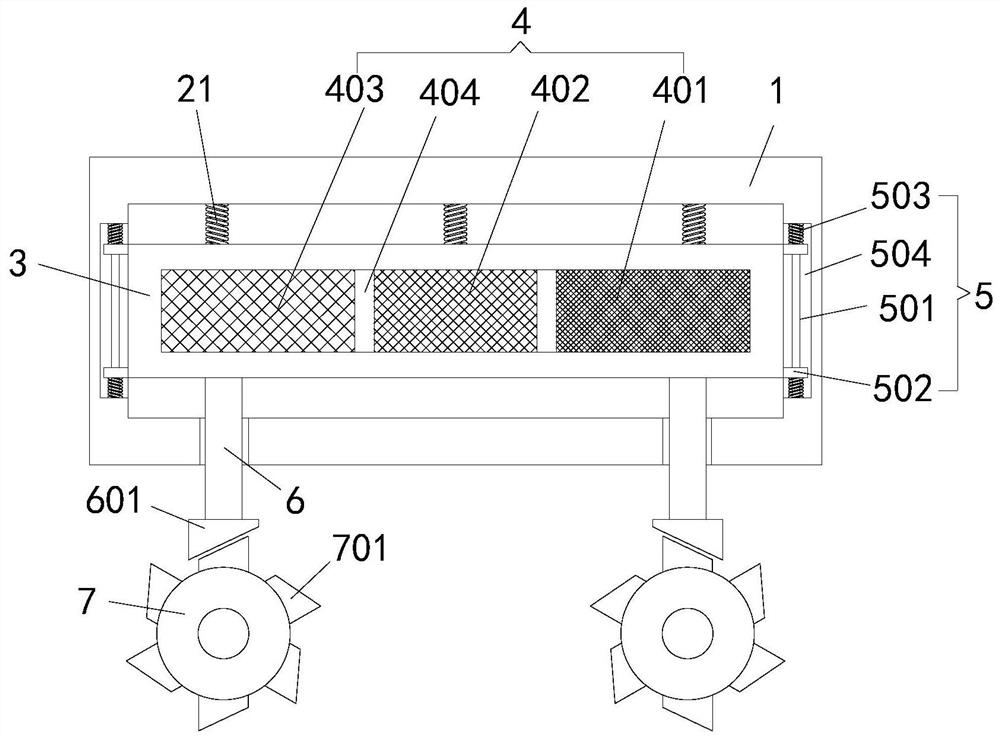

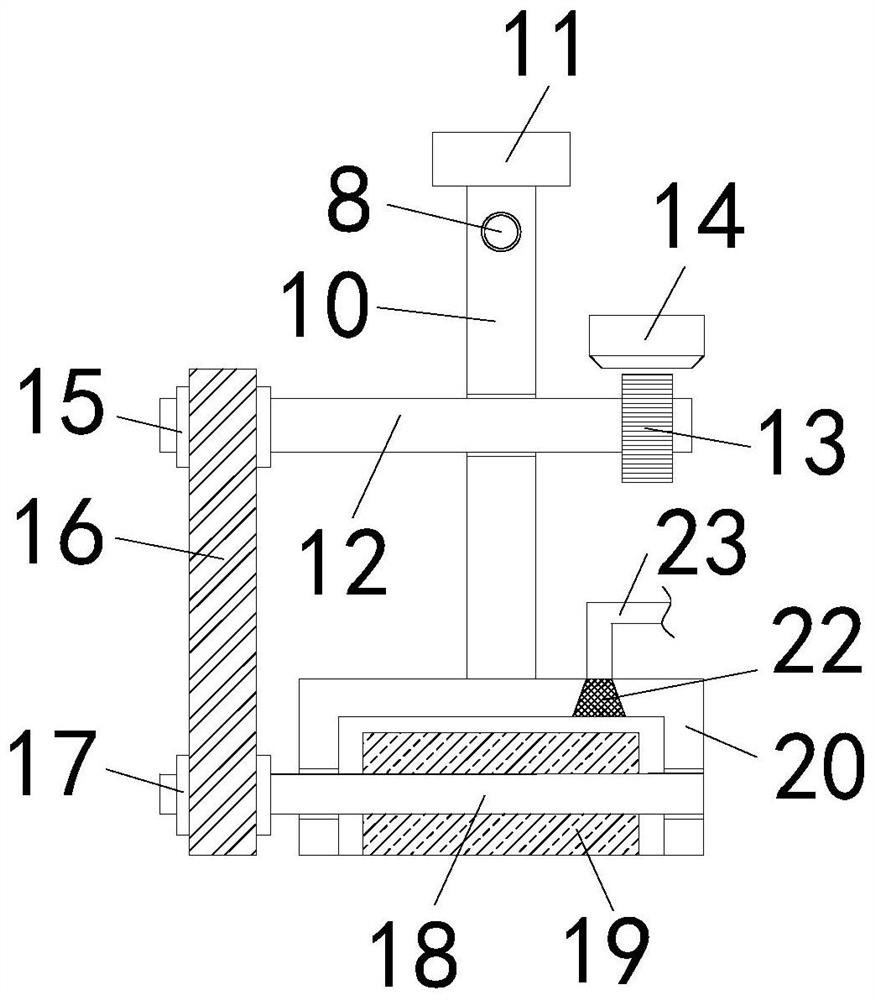

[0043] refer to Figure 1-6 , a screening and dedusting device for multifunctional modified plastic granulation, comprising a body shell 1, an upper end cover 2 and a screening frame 3, the upper end cover 2 is fixedly arranged on the upper end of the body shell 1, and on the top of the upper end cover 2 a There is a feed inlet on the side, and the feed inlet is located directly above the first screen 401, which is used for feeding and screening modified plastic particles. The screening frame 3 is arranged in the body shell 1, and the screening frame 3 The bottom is provided with a grading screen 4, and both sides of the outer wall of the grading sieve 4 are symmetrically provided with limiting parts 5. The limiting parts 5 provide limit support for the screening frame 3, thereby ensuring that the screening frame 3 can shake smoothly and horizontally. There are several groups of damping springs 21 connected between the component 5 and the inner side wall of the body shell 1, a...

Embodiment 2

[0054] refer to Figure 1-6 The difference between this embodiment and Embodiment 1 is that the body shell 1 is provided with a dust suction port relative to the other side wall of the vacuum cleaner 24, the dust suction port communicates with the side wall of the screening frame 3, and a metal suction port is arranged inside the dust suction port. The filter screen, the outward extension of the dust suction port is connected with a dust removal device, and the dust removal device is a pulse dust collector of the SCT4-550 type;

[0055] The two side walls of the bottom of the cleaning frame 20 are respectively provided with several groups of concave tooth grooves, which are used to evacuate and push the plastic particles, which is helpful for the removal of dust and impurities;

[0056] The side wall of the cleaning frame 20 is provided with a top plate 25 through the cavity 27, and the top side of the top plate 25 is provided with a wedge 26, and the wedge 26 extends inwardly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com