Elastic filler demolding treatment method and water treatment demolding equipment

An elastic filler and water treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem of decreased nitrification reaction efficiency in filters, easy agglomeration of fillers, and deterioration of effluent water quality Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

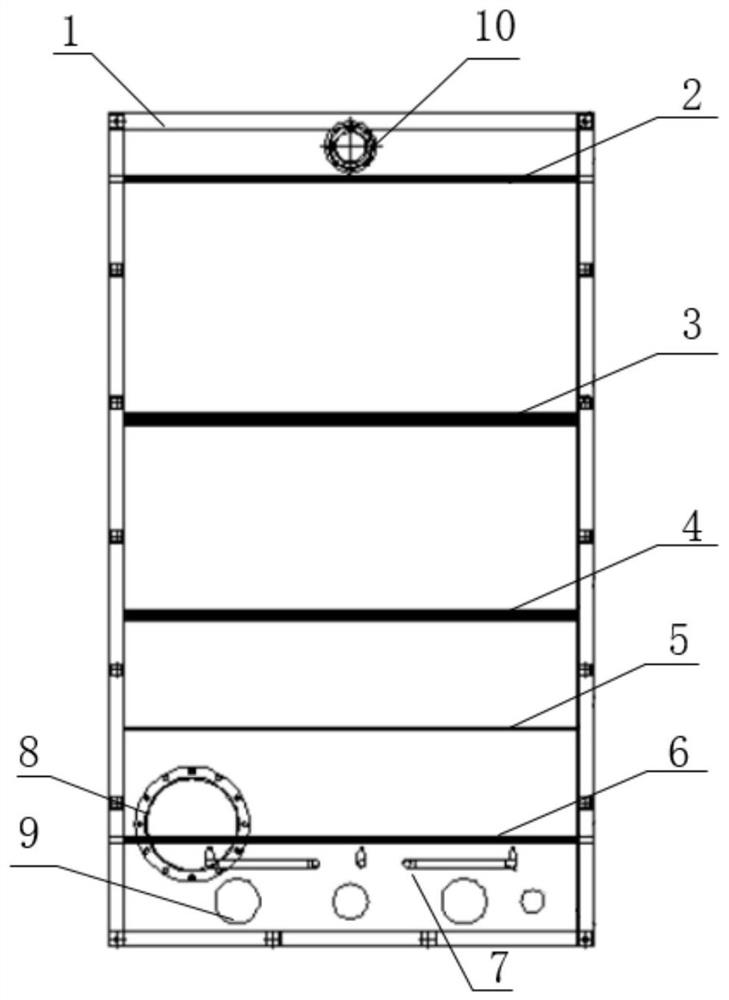

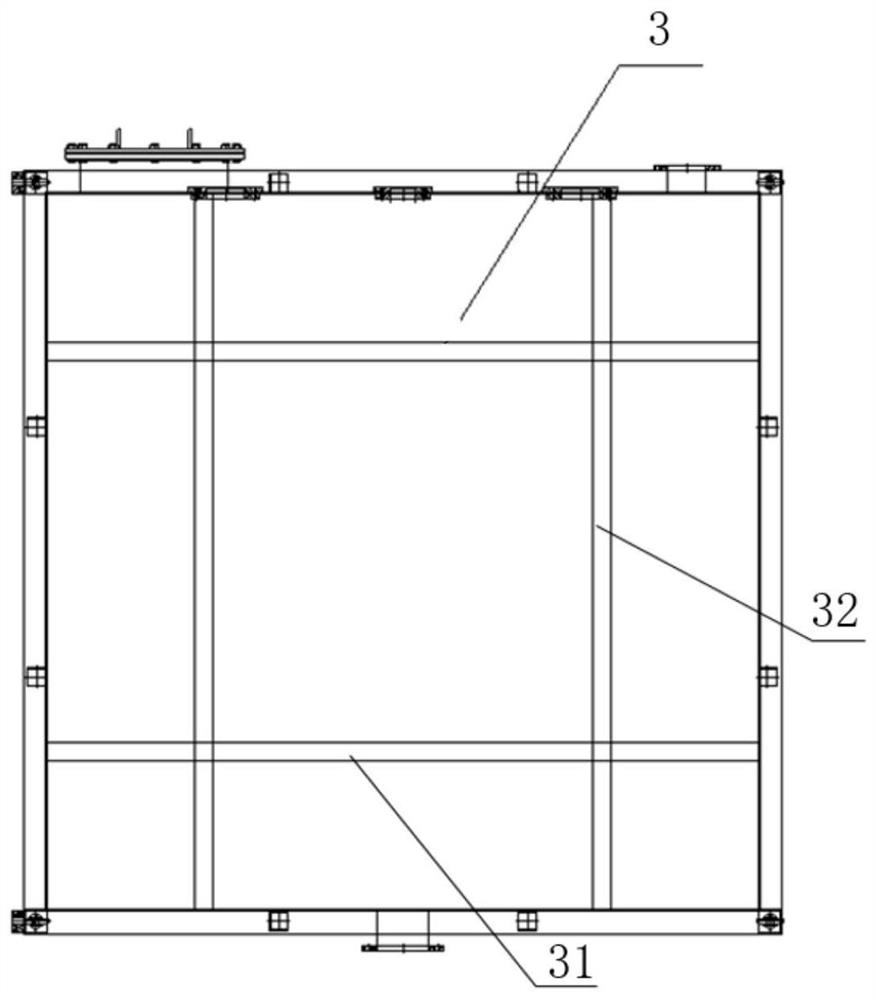

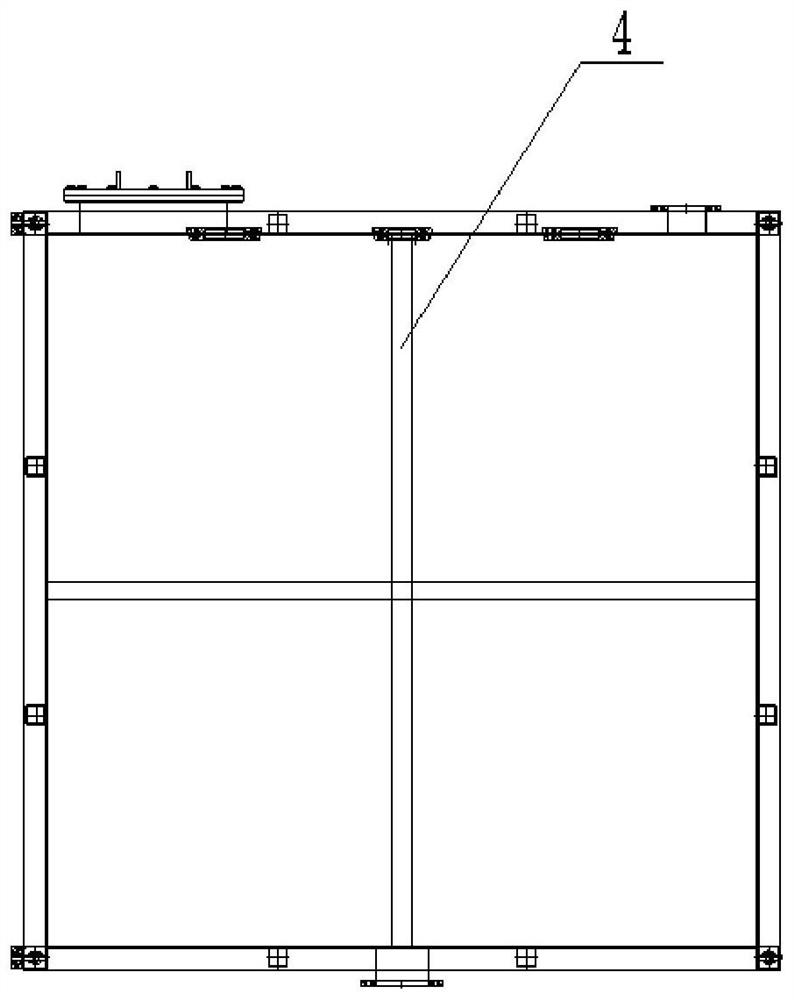

[0060] Embodiments of the present disclosure provide, on the one hand, a water treatment and defilming device, so as to solve or at least partly solve the above-mentioned problem of filler compaction. will now refer to Figure 1-5 Some example embodiments will be described. Note that in the following description, "river black and odorous water body" may be used as an example of treatment. However, the scope of the present disclosure is not limited thereto, and any water treatment and defilming equipment described here can be used within the scope of the present disclosure.

[0061] Such as figure 1 and Figure 5 As shown, generally, the water treatment stripping equipment according to the embodiment of the present disclosure includes a box body 1 and a cutting bracket.

[0062] The top of the box body 1 is open, and there is a storage space inside, which is mainly used to carry the cutting bracket and the filler floating in the middle and upper part of the box body 1; in t...

Embodiment 2

[0079] Such as Figure 6-7 As shown, the embodiments of the present disclosure provide a method for stripping elastic fillers, which is used in the above-mentioned water treatment stripping equipment. The method includes: performing stripping treatment on the elastic fillers during the nitrification process of sewage, The film-removing treatment step includes: the elastic filler is cut and scattered by a plurality of sets of shearing brackets arranged on the moving path of the elastic filler as the water level drops or rises. It can effectively solve the problem of filler compaction, realize effective stripping of filler, increase water permeability and air permeability of filler, thereby improving sewage treatment efficiency and restoring effluent water quality.

[0080] The type of sewage to be treated in this embodiment is river black and odorous water body, the inflow of the river sewage is 1000m3 / d, the influent ammonia nitrogen≤30mg / L, COD≤100mg / L, total phosphorus≤1mg / L...

Embodiment 3

[0095]The difference between embodiment 3 and embodiment 2 is that: in the initial emptying extrusion stage, the volume of the elastic packing is deformed to 55% of the original stacked volume; the remaining sludge in the packing is discharged through the first deformation extrusion, which is convenient Extrusion and stripping of the elastic packing in the later stage; the compaction of the packing can be effectively relieved; if the direct aeration backwashing is not performed for the first extrusion, the amount of sludge in the system is too large, which will cause incomplete stripping; the second emptying and extrusion The pressing stage includes: deforming the volume of the elastic filler to 75% of the original stacked volume, squeezing out the dirt in the elastic filler again, and completing the film removal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap