Organoid forming chip based on microfluidic technology, and working method of organ-like forming chip

A microfluidic technology and organoid technology, applied in the field of biological microfluidics, can solve the problems such as the inability to strictly guarantee the uniform size of the organoids and the uneven sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

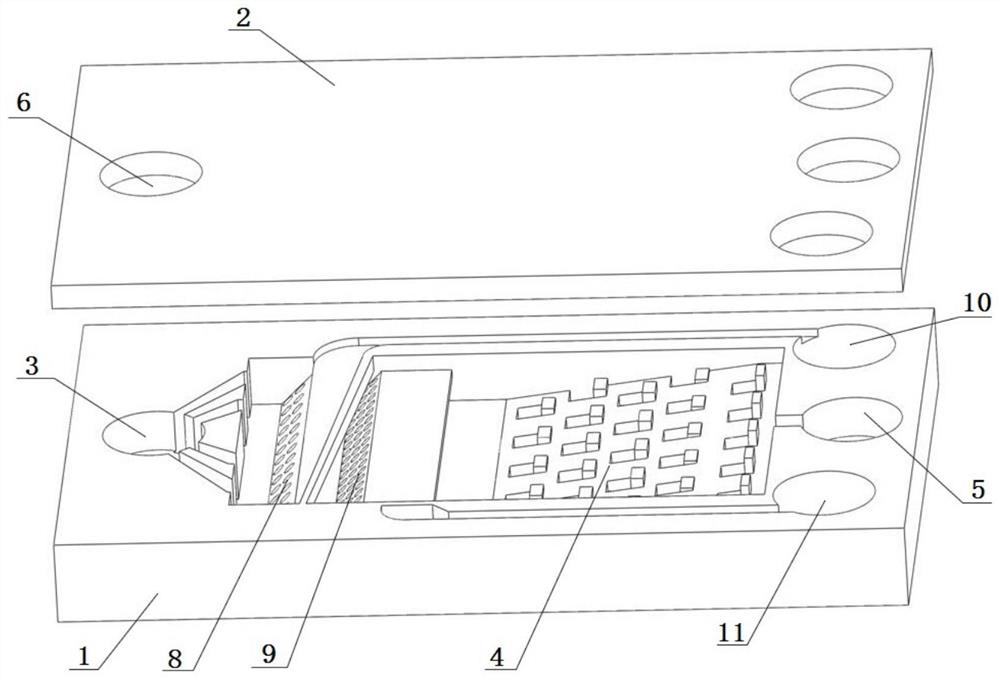

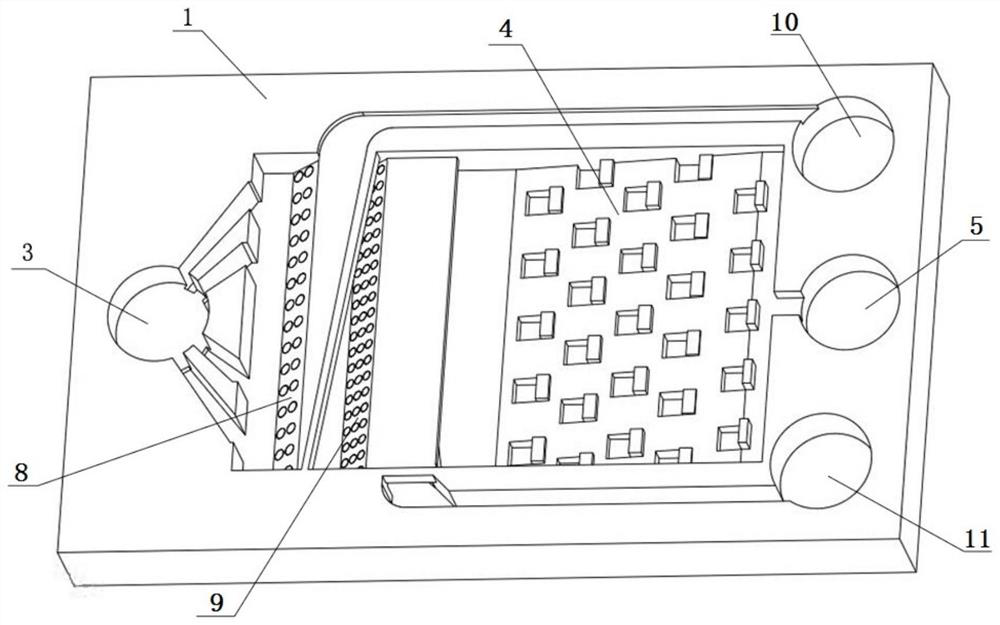

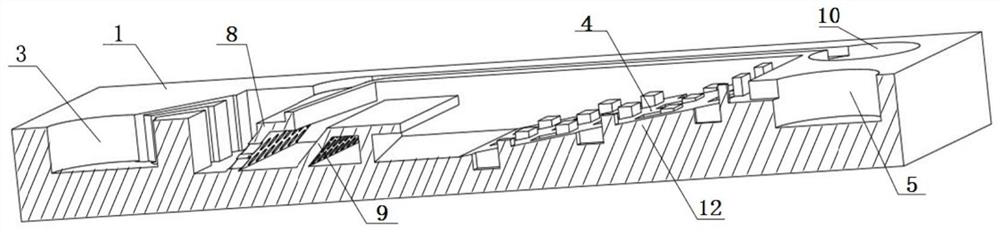

[0040] Such as Figure 1 to Figure 3 As shown, an organoid forming chip based on microfluidic technology, which includes a bottom flow channel 1 and a top cover plate 2 covered on the top of the bottom flow channel 1, and the bottom flow channel 1 is sequentially provided with A liquid flow inlet 3, a culture pool array 4 communicated with the liquid flow inlet 3, and a culture liquid outlet 5 for discharging the liquid flow passing through the culture pool array 4, the culture pool array 4 is connected to the bottom flow The bottom surface of the channel 1 is inclined at a certain angle, and the end of the culture pool array 4 close to the culture solution outlet 5 is higher than the end of the culture pool array 4 close to the liquid inflow inlet 3, and the culture pool array 4 is inclined. The micro-tissue blocks in the micro-tissue block suspension can be blocked from flowing along the flow direction of the micro-tissue block suspension to fill up each culture pool 41 in t...

Embodiment 2

[0052] A working method for forming an organoid chip based on microfluidic technology, which includes the following steps:

[0053] S1. After the primary tissue is cut and enzymatically treated in the laboratory, a suspension of microtissue blocks is formed;

[0054] S2. The injection liquid of the micro-tissue block suspension flows into the inlet 3, and then the micro-tissue block suspension passes through the primary screening structure 8 and the secondary screening structure 9 sequentially under the driving force, and moves to the culture pool array 4, wherein, the micro-tissue block suspension cannot pass through The microtissue fragments of the primary screening structure (8) are drained through the flow channel to the primary screening liquid outlet (10) for collection, and the microtissue fragments that can pass through the secondary screening structure (9) are drained through the flow channel to the secondary screening liquid outlet (11) to collect;

[0055] S3. When...

Embodiment 3

[0065] This embodiment is similar to Embodiment 2, and the difference is that the following steps are also included between the step S3 and the step S4:

[0066] S5. After digesting the oversized tissue collected at the outlet 10 of the primary screening fluid, mix it again with the suspension of the microtissue block collected at the outlet 5 of the culture fluid, and then mix it with the injection fluid inlet 3, and repeat steps S2 to S3, thus The process is repeated several times, so as to collect the same amount of microtissues in each culture pool 41 .

[0067] Other steps in this embodiment are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com