Tamping device for foundation engineering construction

A technology for tamping devices and basic engineering, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of difficult to ensure the level of laying floor tiles, affecting the construction process, and insufficient power supply of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

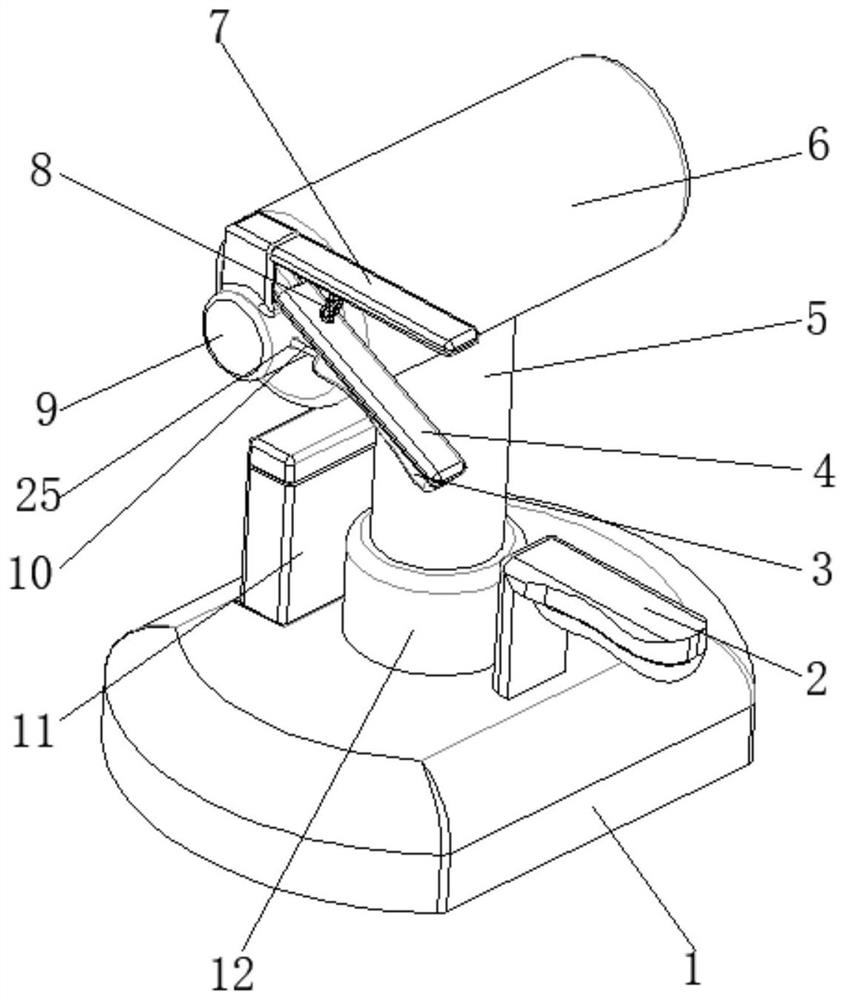

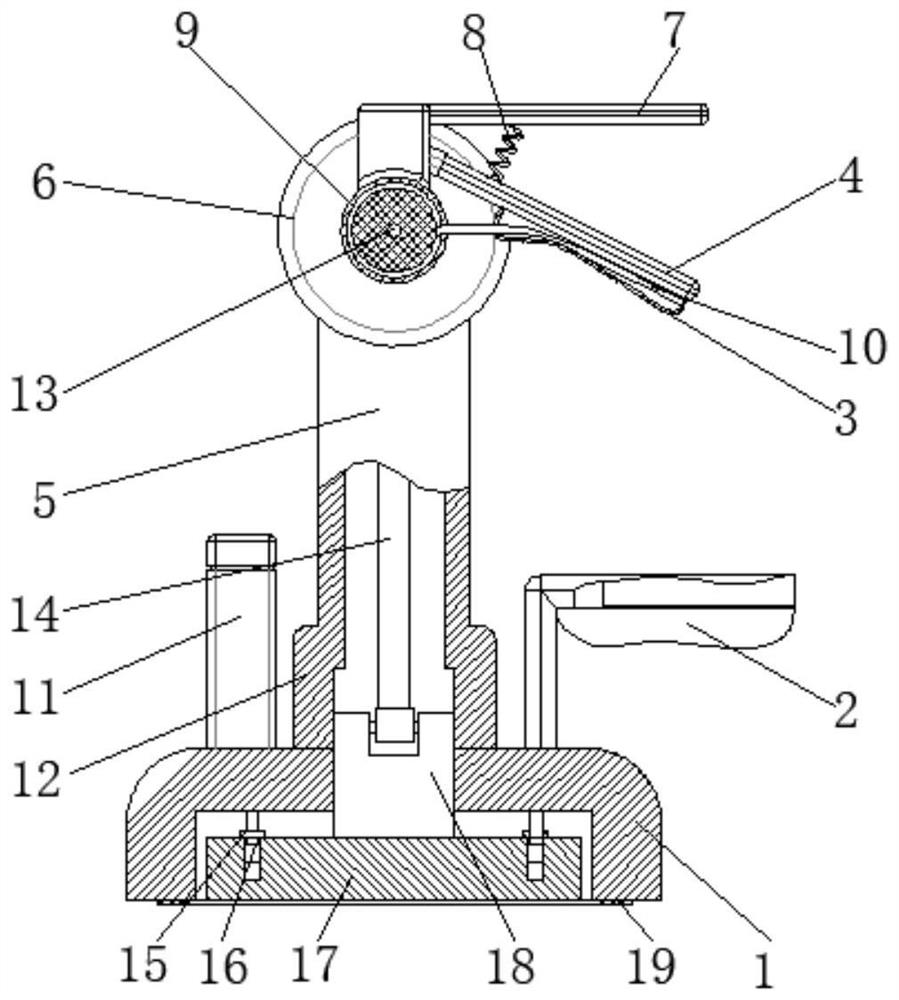

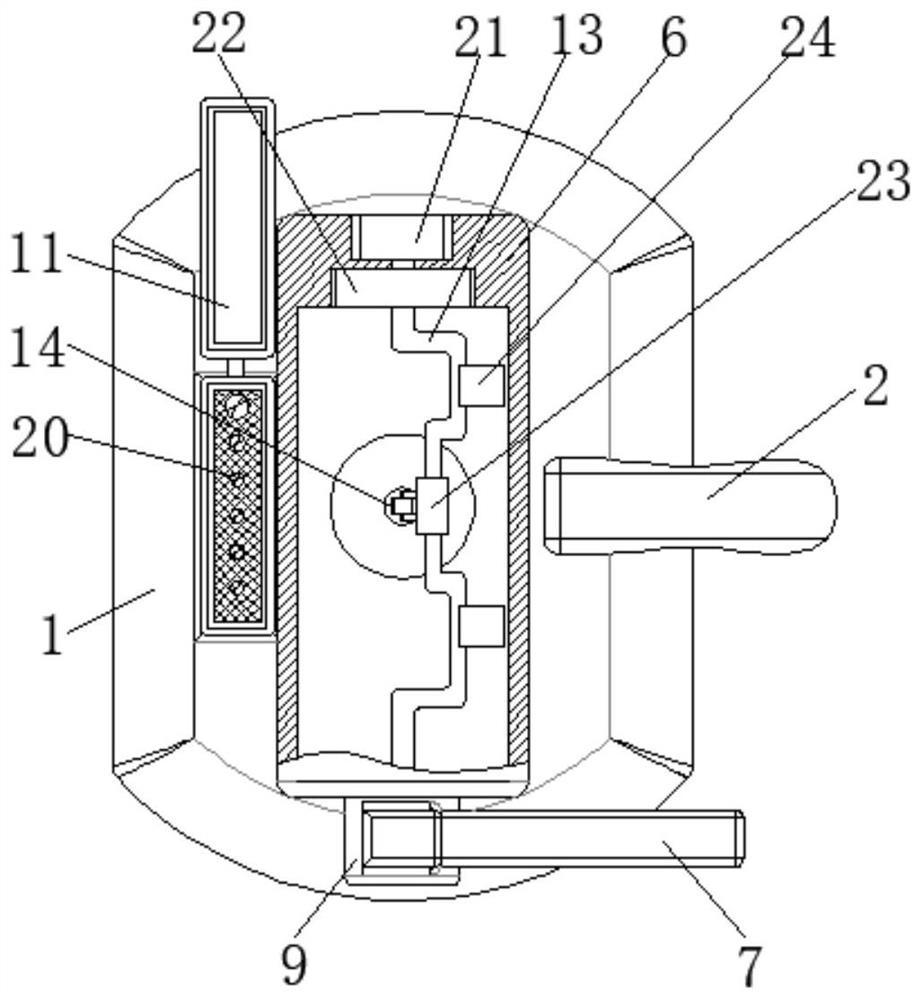

[0033] Such as Figure 1-6 As shown, the embodiment of the present invention provides a kind of tamping device for basic engineering construction, comprising a base 1, the upper surface of the base 1 is provided with a horizontal bubble 26, by observing the position of the bubble in the horizontal bubble 26, it can be known whether the base 1 is in a horizontal state, The middle part of the upper surface of the base 1 is fixedly connected with a guide cylinder 12, which is used for the sliding of the weight 18 and plays a guiding role. The upper surface of the guide cylinder 12 is fixedly connected with a connecting column 5, and the upper end surface of the connecting column 5 is fixedly connected with a connecting cylinder. 6;

[0034] A crankshaft 13 is rotatably connected between the left and right side walls of the connecting cylinder 6, and its connection and driving function. The right side end of the crankshaft 13 is fixedly connected with a drill joint 21, which will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com