Prefabricated assembled pier and connecting method thereof

A prefabricated assembly and pier technology, which is applied in erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as unguaranteed grouting quality, decreased ductility, and project quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

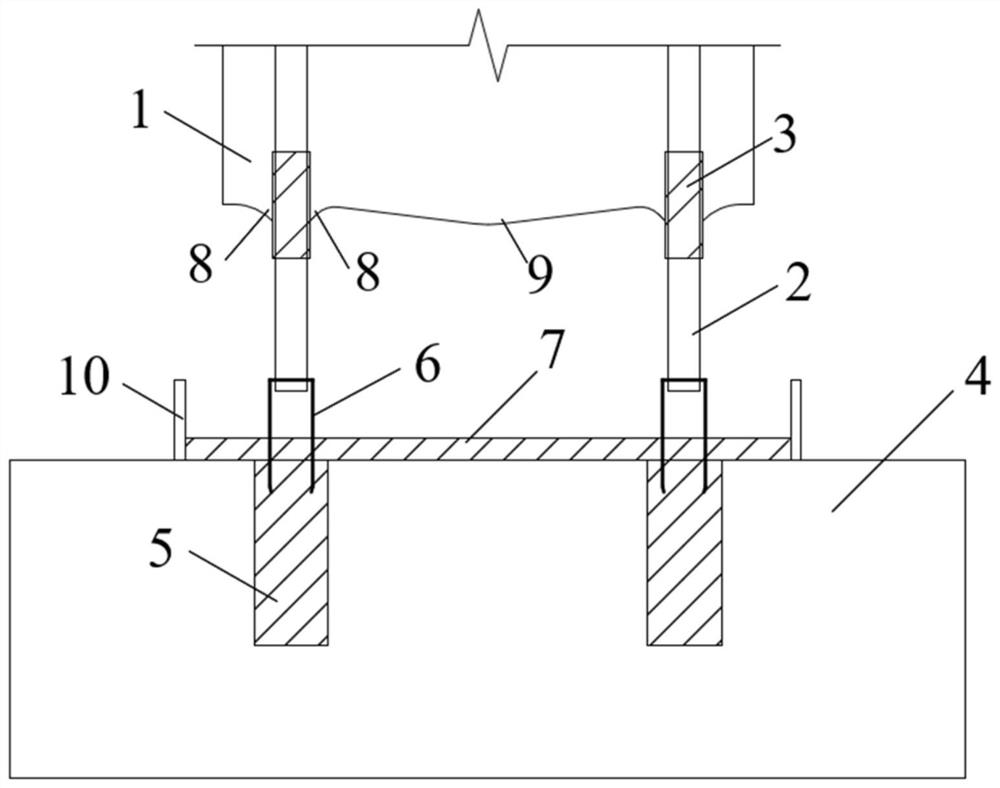

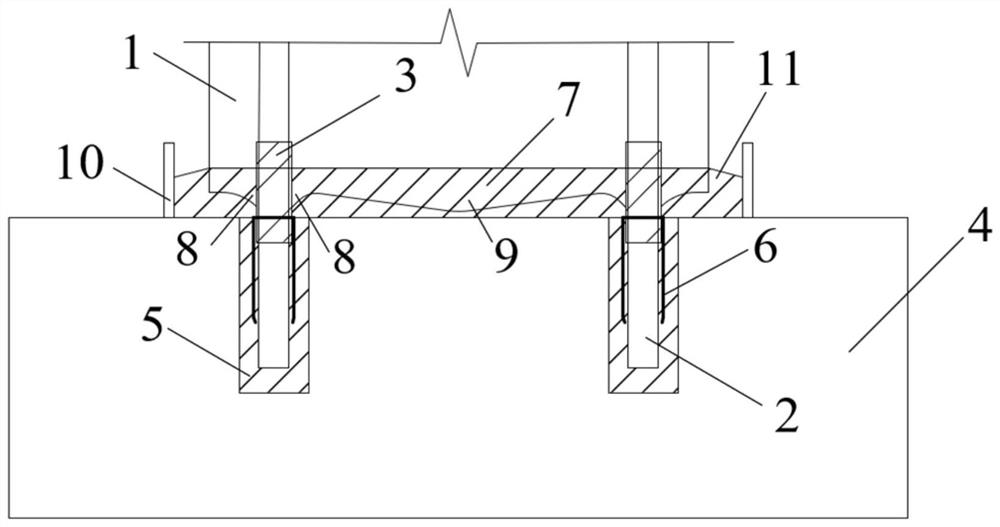

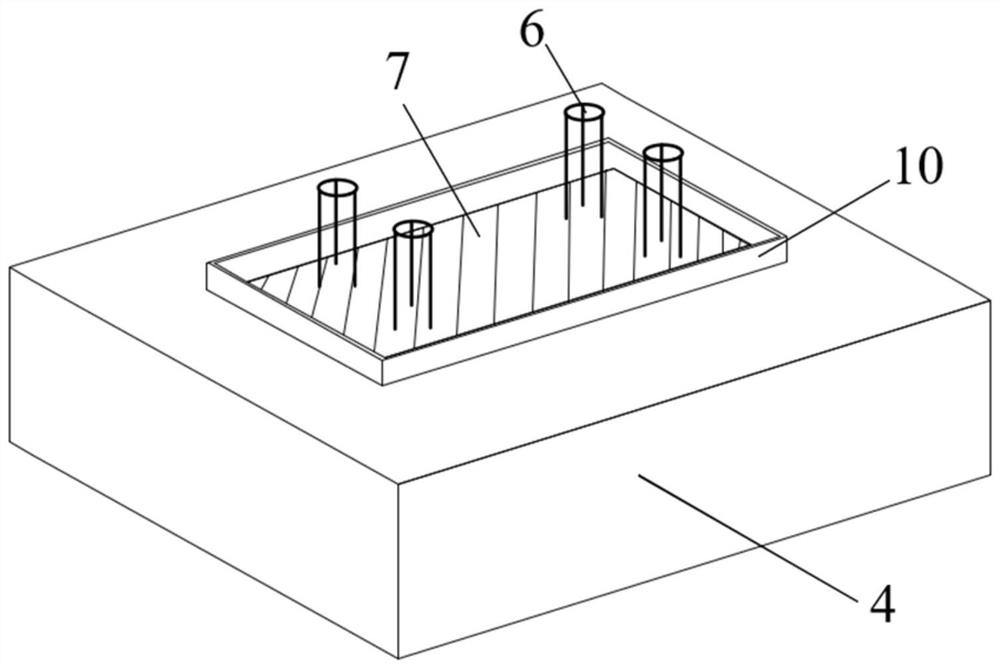

[0042] A prefabricated assembled bridge pier, such as figure 1 and figure 2 As shown, it includes the pier column 1 and the cap 4. The main reinforcement 2 is pre-embedded in the pier column 1. The main reinforcement 2 protrudes from the bottom of the pier column 1 for a certain length. In the pier column 1, the other part is exposed on the part where the main reinforcement 2 protrudes from the pier column 1, and the bottom of the pier column 1 is reserved at the center with a large cone 9 protruding toward the cap 4. The bottom of the pier column 1 A small cone 8 protruding toward the cap 4 is reserved at the root of the main rib 2, and the protruding length of the large cone 9 is greater than that of the small cone 8;

[0043] A grouting bellows 5 is pre-embedded in the bearing platform 4, the top of the grouting bellows 5 is flush with the top surface of the bearing platform 4, and a guiding device 6 is inserted in the grouting bellows 5, and the guiding device 6 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com