Heat insulation and heat preservation building wall and construction method thereof

A technology for building walls and thermal insulation, applied in thermal insulation, construction, building components, etc., can solve problems such as poor thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

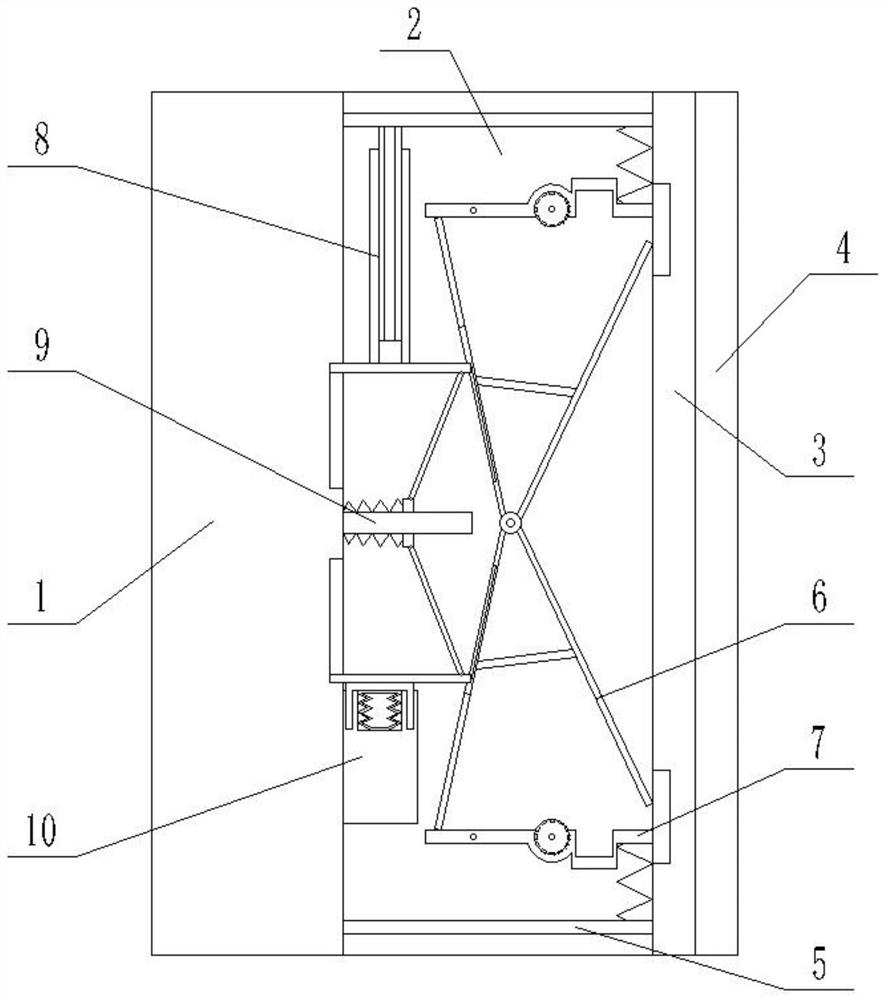

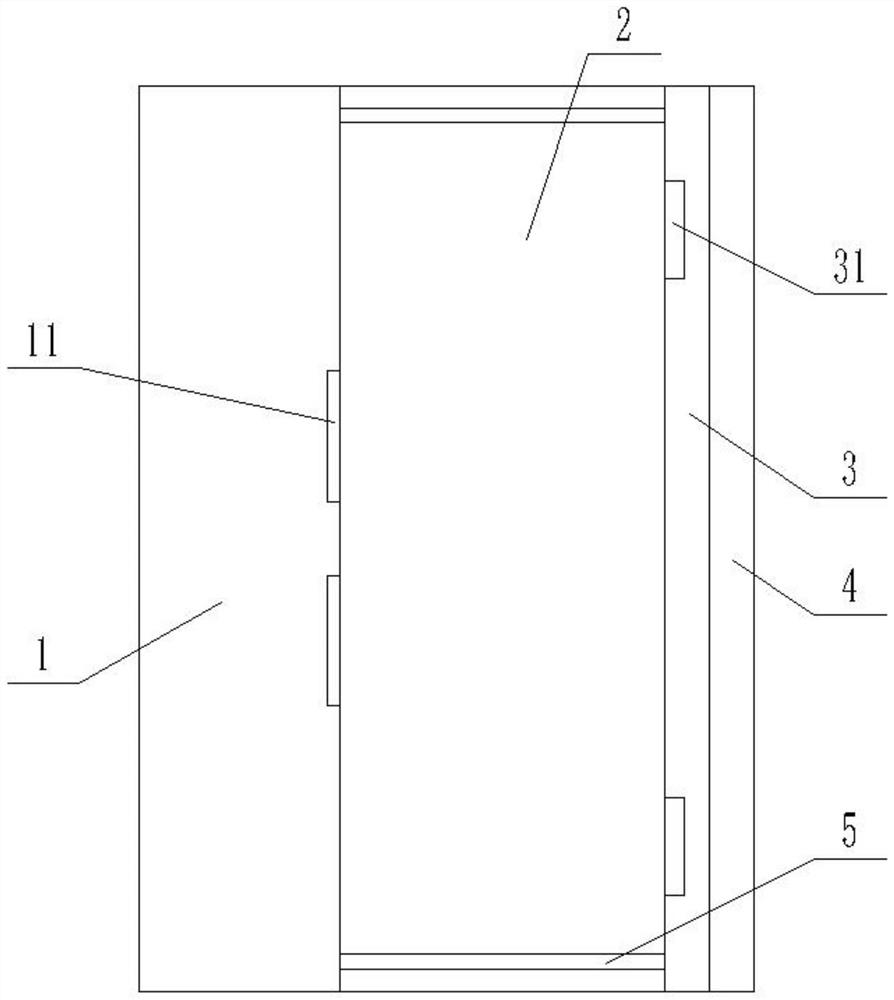

[0024] Specific implementation mode one: as Figure 1-9 As shown, this embodiment describes a heat-insulating building wall, including an outer wall 1, a plurality of vertical partitions 2, a heat insulation board 3, an exterior decoration layer 4, a plurality of transverse partitions 5, and a plurality of transmission Device 6, a plurality of rotating devices 7, a plurality of control devices I8, a plurality of linkage devices 9 and a plurality of control devices II10; a heat insulation cavity is provided between the outer wall body 1 and the heat insulation board 3, and the heat insulation cavity A plurality of vertical partitions 2 and a plurality of horizontal partitions 5 are provided inside, and a plurality of vertical partitions 2 and a plurality of horizontal partitions 5 are equally divided into several cavities, and each vertical partition 2 and a plurality of horizontal partitions 5 are It is fixedly connected between the outer wall body 1 and the heat insulation bo...

specific Embodiment approach 2

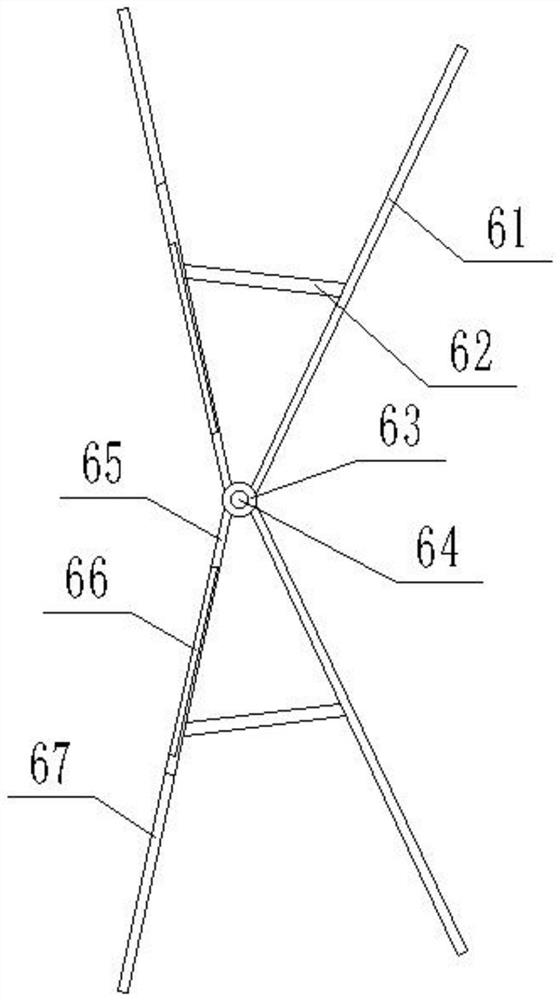

[0025] Specific implementation mode two: as image 3 , 4 As shown, this embodiment is a further description of Embodiment 1. Each transmission device 6 includes two metal plates I61, two connecting rods 62, two rotating cylinders 63, a shaft center 64 and two metal Plate II 65; the axis 64 is fixedly connected to the vertical partitions 2 on both sides of the corresponding cavity; the two rotating cylinders 63 are connected to the axis 64 through bearings; each of the rotating cylinders 63 is respectively fixed A metal plate I61 and a metal plate II65 are connected, the metal plate II65 on the two rotating cylinders 63 is close to the heat shield 3, the metal plate I61 is close to the outer wall 1, and the angle between the two metal plates II65 is 150° °, the angle between each metal plate I61 and the metal plate II65 on the same rotating cylinder 63 is less than 30°; The distance between them is equal; the corresponding connecting rod 62 is fixedly connected between the co...

specific Embodiment approach 3

[0026] Specific implementation mode three: as Figure 5 As shown, this embodiment is a further description of Embodiment 1. Each of the rotating devices 7 includes a rotating plate I71, a rotating shaft 72, an arc-shaped housing 73, a rotating cylinder 74, a U-shaped plate 76, a spring I77 and a rotating Plate II78; one end of the rotating plate I71 is fixedly connected with an arc-shaped housing 73, and the rotating plate I71 is connected to the rotating shaft 72 through a bearing; the rotating shaft 72 is fixedly connected to the vertical partitions 2 on both sides of the cavity; The other end of the arc-shaped shell 73 is fixedly connected with a U-shaped plate 76; the other end of the U-shaped plate 76 is fixedly connected with a rotating plate II78; one end of the spring I77 is fixedly connected with the rotating plate II78, and the other end of the spring I77 Fixedly connected on the corresponding diaphragm 5 in the cavity; the rotating cylinder 74 is connected in the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com