Blade, fan and aircraft environment control system

A blade and airfoil technology, applied in the field of aircraft air conditioning, can solve problems such as high shaft power, increased aircraft fuel consumption, and reduced aircraft cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

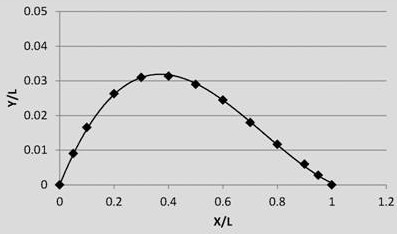

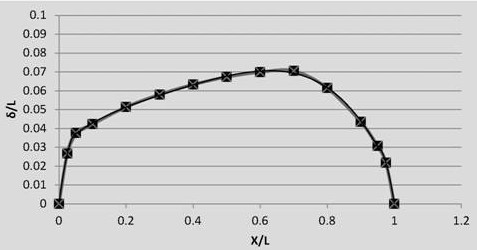

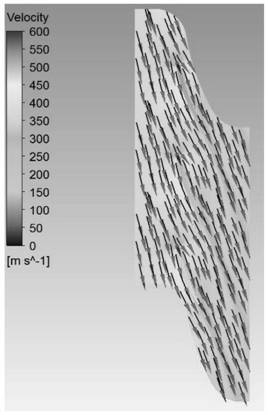

[0035] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, the blade includes a trailing edge 1, a leading edge 2, a trailing edge 3 and a blade tip 4. The line connecting the points is the chord, the length of the chord is the chord length, and the distance between the position of the maximum airfoil thickness of the wing section and the leading edge point occupies 30% to 40% of the entire chord length. Preferably, the distance between the position of the maximum thickness of the airfoil and the point of the leading edge of the airfoil section occupies 35%-40% of the entire chord length. The leading edge point refers to the frontmost point of the wing section, and the trailing edge point refers to the rearmost point of the wing section.

[0036] For fan blades in the related art, the distance between the position of the maximum airfoil thickness on the chord and the leading edge point generally occupies 10% to 20% of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com