Thermal infrared imager working temperature measuring device and focal plane self-adaptive compensation method

An infrared thermal imager and self-adaptive compensation technology, which can be used in measurement devices, radiation pyrometry, optical radiometry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

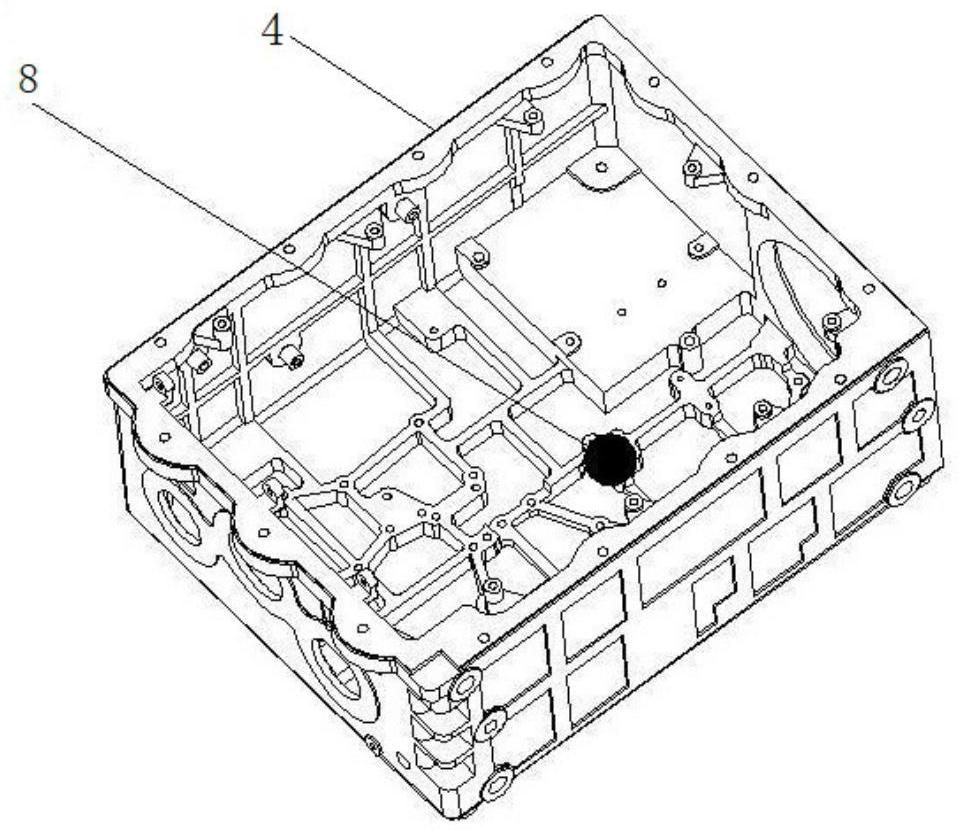

[0064] like figure 1 As shown, the transistor element used for temperature measurement is installed near the position of the internal focusing mirror of the infrared thermal imager 4, and one transistor element 8 can be installed to measure an operating temperature, and multiple transistors can also be installed at different positions where the temperature needs to be monitored. The element 8 is used to measure multiple temperatures, and this embodiment takes one temperature measurement as an example for illustration.

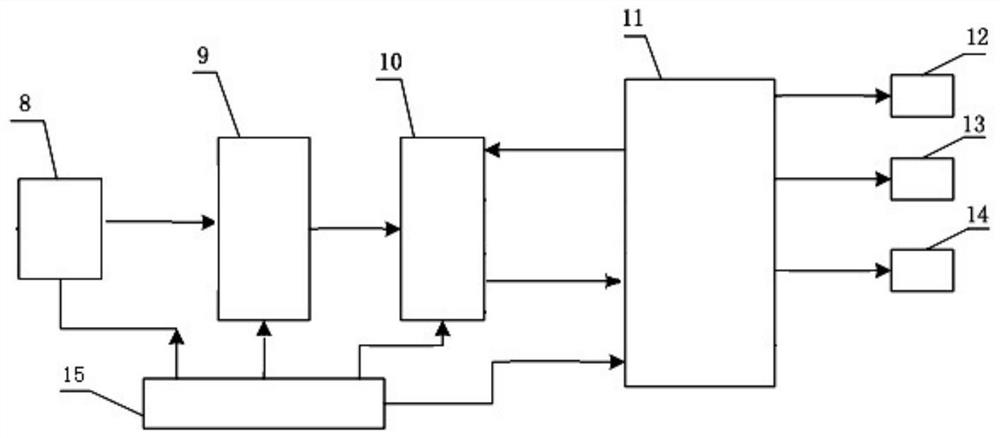

[0065] like figure 2 As shown, the infrared thermal imager operating temperature measuring device of the present invention consists of a transistor element 8, an operational amplification conditioning circuit 9, an analog-to-digital conversion circuit 10, a DSP digital signal processor 11, a memory module 12, an image display module 13, and a serial port communication module 14 and the power supply circuit 15 and so on.

[0066] The transistor element 8, the...

Embodiment 2

[0090] according to Figure 7 The flow chart of the present embodiment shown, at first, set up a set such as Figure 5 As shown in the calibration test environment, configure a thermostat 2 that can provide a simulated working environment temperature and has a thermostat observation window 3, and place the assembled infrared thermal imager 4 inside; observe in the thermostat outside the thermostat 2 A collimator 5 is arranged at the window 3 and placed on the shock-absorbing support work platform 6 , and a four-bar target simulation test target for testing the image performance of the infrared thermal imaging camera 4 is set on the collimator 5 . After the infrared thermal imager 4 is started to work, adjust the position of the infrared thermal imager 4 and the lens, and face the external collimator 5 through the observation window 3 of the thermostat, and the following will appear on the display: Image 6 The output video image shown is the observation image of 4 pairs of fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com