Solid engine grain health monitoring and life evaluation method

A solid motor and health monitoring technology, applied in the direction of material impedance, etc., can solve the problems of the aging state of the solid rocket motor grain structure and the relationship between the life and the life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method for health monitoring and life evaluation of solid motor grains according to the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

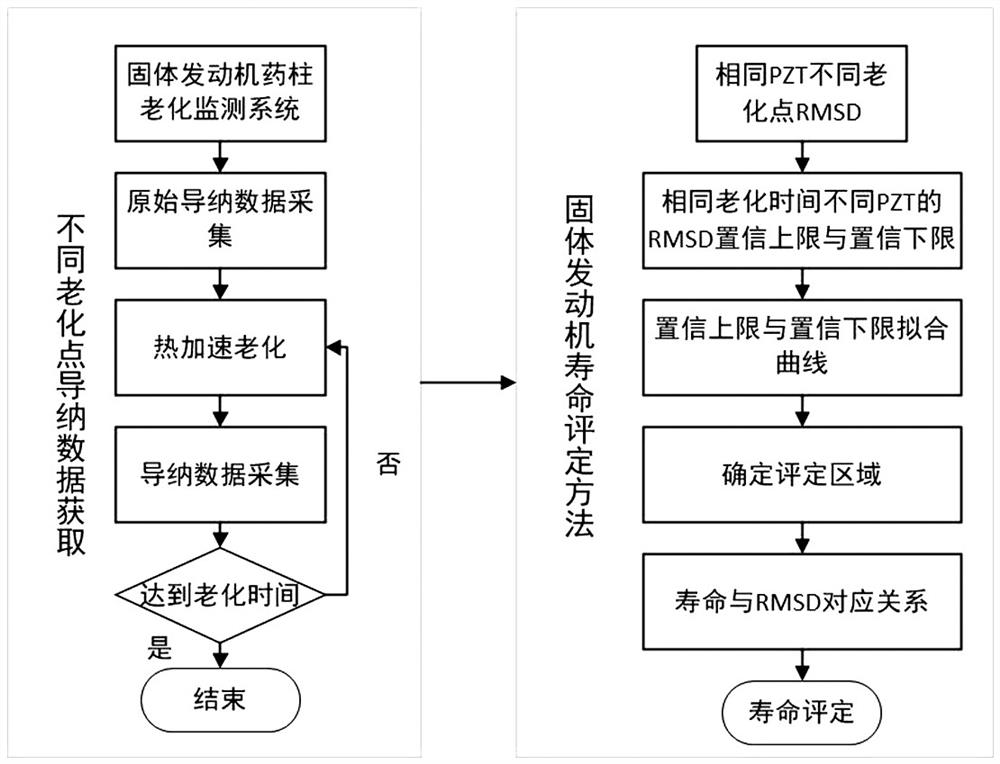

[0025] The solid motor grain health monitoring and life assessment method described in the embodiment of the present disclosure, such as figure 1 shown, including the following steps:

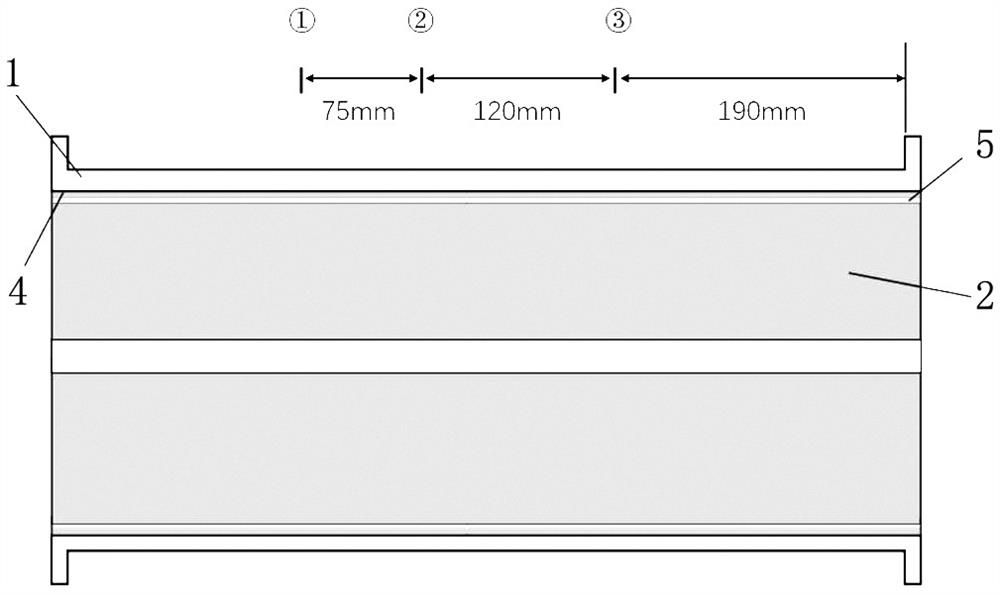

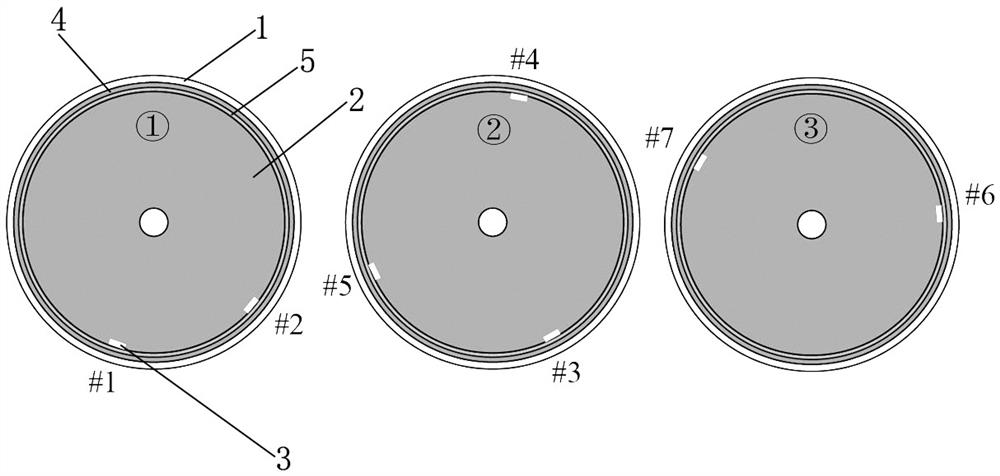

[0026] Step 1. When the lining layer 5 is painted on the inner surface of the engine heat insulation layer 4 and reaches the semi-cured state, N PZT sensors 3 are pasted on different positions of the lining layer 5, and numbered to construct a sensor array; then use the lining layer 5 material Manually paint and seal the wire parts of the sensor with slurry, and then pour, to establish a solid engine grain 2 aging monitoring system;

[0027] Step 2, original admittance data collection; by setting n sampling points, adopt broadband test collection to determine the electromechanical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com