UHPC-NC superimposed bridge deck steel-concrete composite beam hogging moment area section checking calculation method

A technology of steel-concrete composite beams and negative bending moment areas, which is applied in bridges, bridge materials, bridge construction, etc., can solve the problems that cannot consider the calculation requirements of the construction sequence of composite beams, and cannot consider the nonlinear loading process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

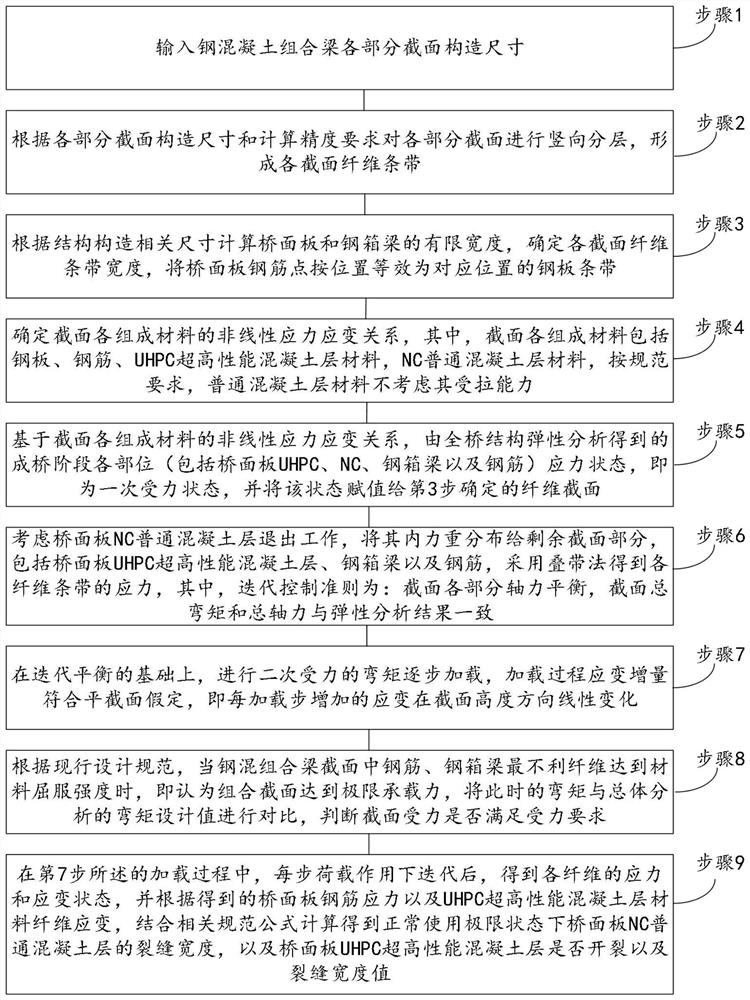

[0042] Such as figure 1 As shown, as the first embodiment of the present invention, a UHPC-NC laminated deck steel-concrete composite beam section checking method for the negative moment zone is provided, and the method includes:

[0043] Step 1, input the cross-sectional structural dimensions of each part of the steel-concrete composite beam;

[0044] Step 2, according to the structural size and calculation accuracy requirements of each section section, vertically layer each section section to form fiber strips for each section;

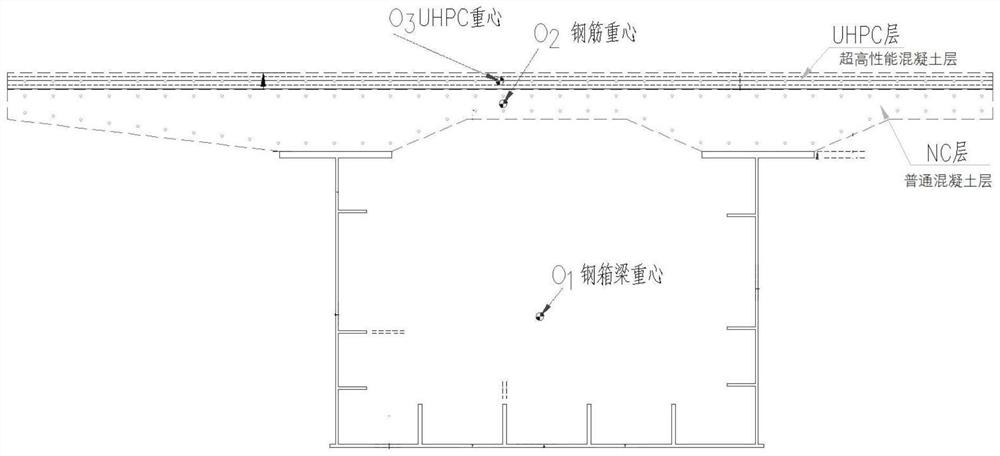

[0045] Step 3, calculate the finite width of the bridge deck and steel box girder 1 according to the relevant dimensions of the structural structure, determine the width of the fiber strips of each section, and equivalently position the steel bars of the bridge deck as steel strips at the corresponding positions;

[0046] Step 4, determine the nonlinear stress-strain relationship of each component material of the section, wherein, each component ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com