Bionic constant-temperature antenna shell structure

An antenna shell and constant temperature technology, applied to antennas, antenna parts, antennas suitable for movable objects, etc., can solve the problem of poor wave transmission performance of the heat-proof layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

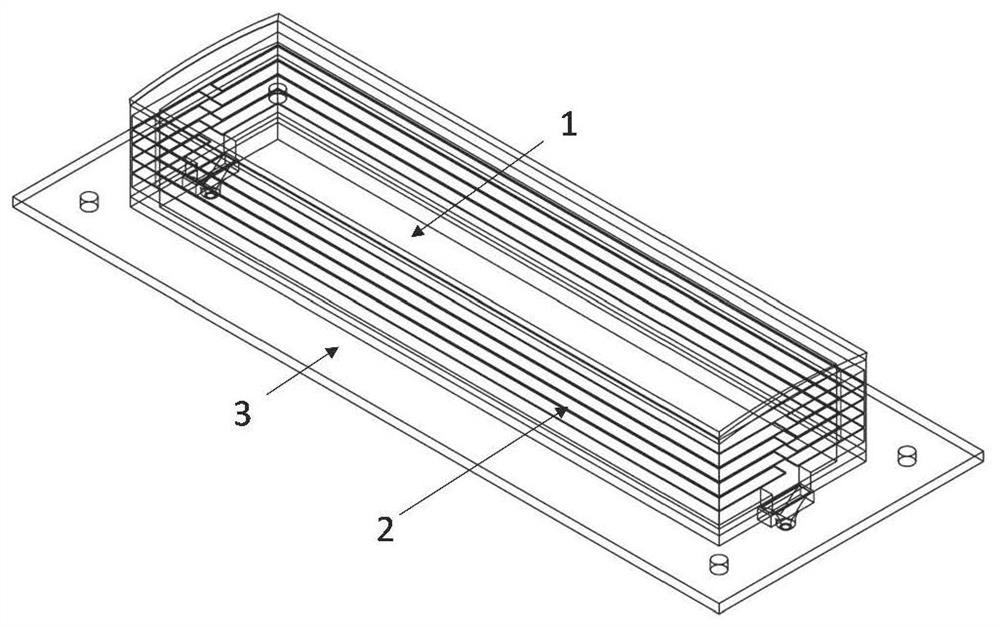

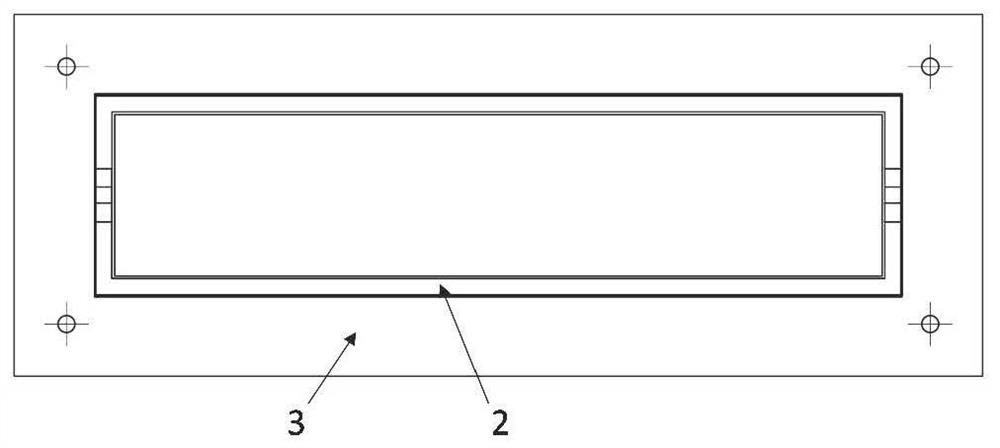

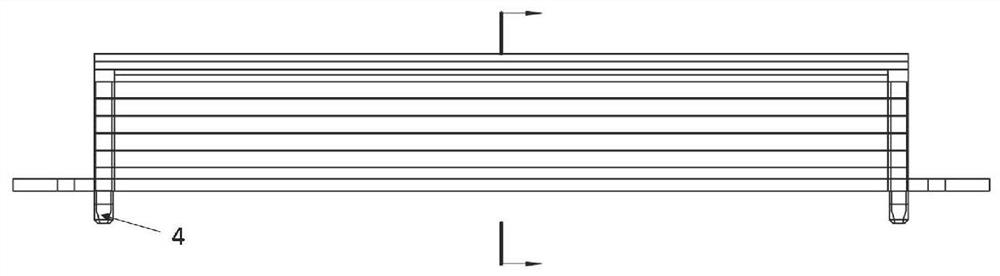

[0036] In an embodiment of the present invention, a bionic constant temperature antenna housing structure is provided, including an epidermis layer, a corium layer and a skeleton layer. The skin layer has the functions of bearing and heat insulation, and the service temperature of the skin layer is 100-2000°C. The epidermal layer includes an outer wall plate 1 and a wave-transmitting layer 5; the cortical layer includes a side wall plate 2 and a pipe joint 4; the skeleton layer is composed of a bottom plate 3, and its structure is as follows Figure 1 ~ Figure 2 shown.

[0037] The outer wall panel 1 is a thin-walled metal structure maintaining an aerodynamic shape, and the wave-transmitting layer 5 is a non-metallic thin-wall structure resistant to high temperature and wave-transmitting. The side wall panel 2 has a cavity structure, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com