Wind path system of compound tea withering machine

A technology of withering machine and tea leaves, which is applied in the field of air duct system of compound tea withering machine, which can solve the problems of uneven withering degree of compound tea withering machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

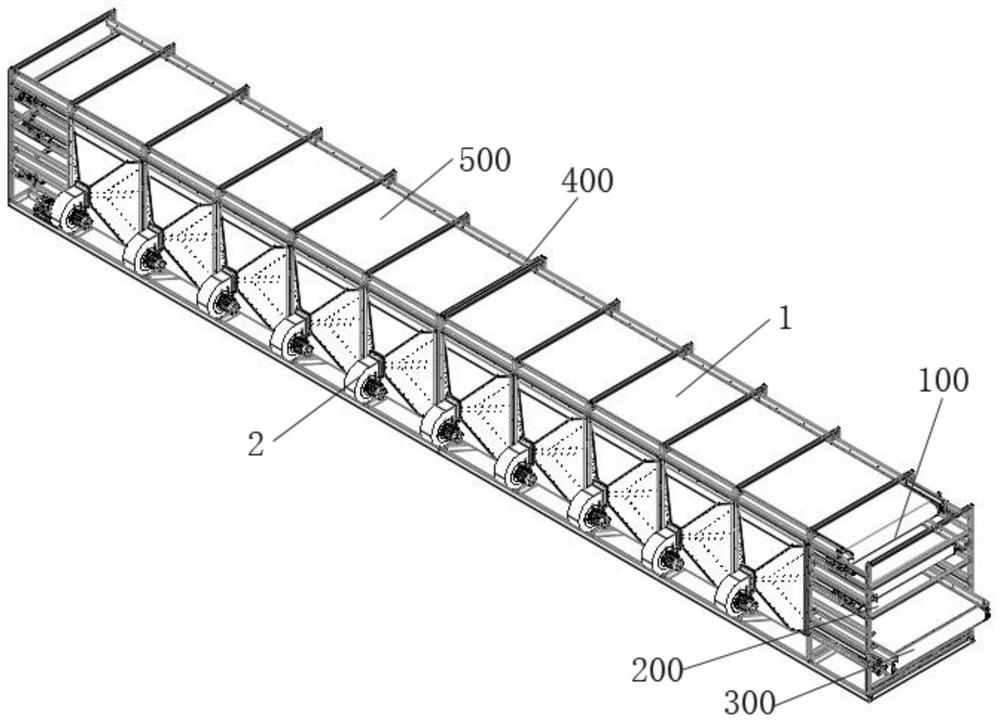

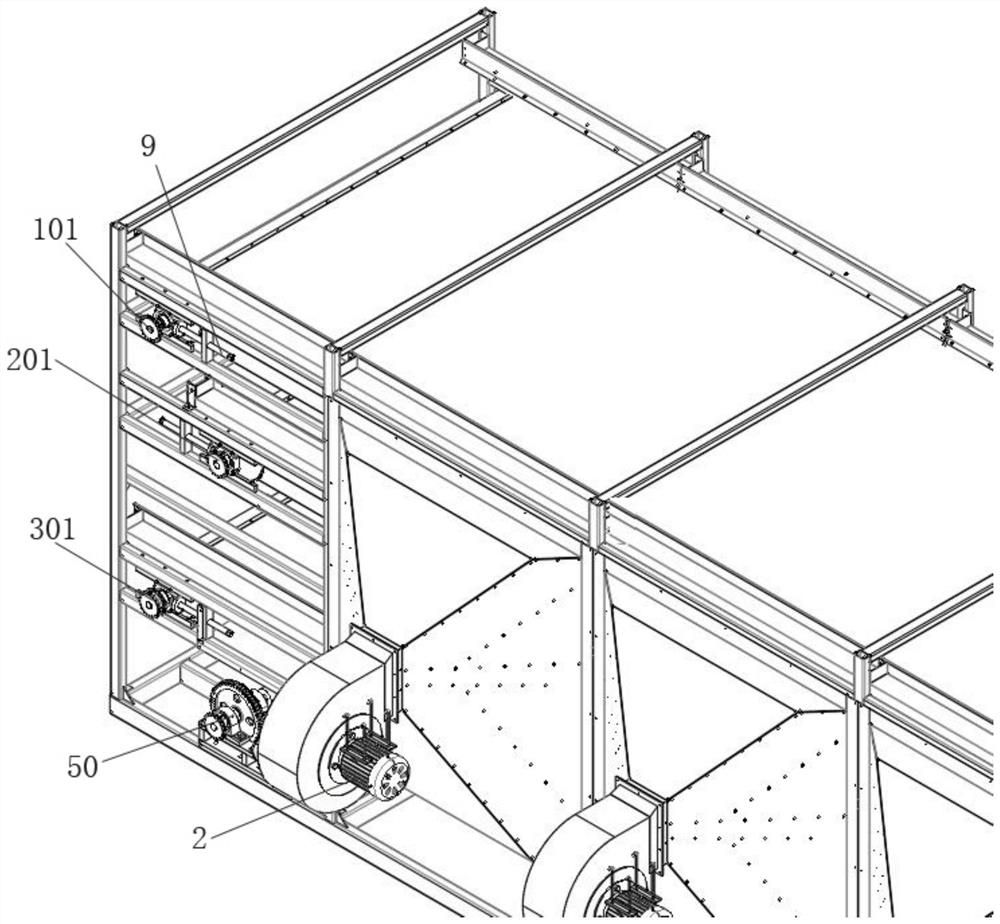

[0025] Such as figure 1 and figure 2 As shown, the air duct system of the compound tea withering machine adopts a three-layer structure, which is respectively the first-layer frame 100, the second-layer frame 200 and the third-layer frame 300, each layer uses a mesh belt 1 to place tea leaves, and the adjacent layers The height between them gradually increases from high to low, and the height between the first layer frame 100 and the second layer frame 200 is smaller than the height between the second layer frame 200 and the third layer frame 300 .

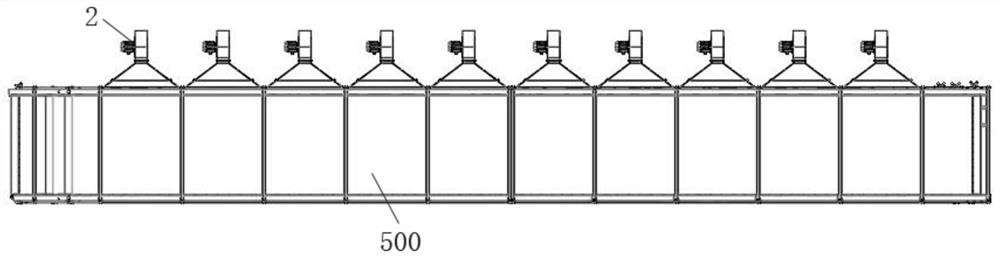

[0026] The air path system of the compound tea withering machine is provided with a plurality of evenly arranged partitions 400 from front to back, and fans 2 are installed between adjacent partitions 400, and the two sides of the fans 2 are respectively fixed on the partitions. The position of each layer is divided into equal withering areas 500 by partitions 400 , and similarly, the withering areas 500 of each layer also corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com