Metal plate stamping mechanism of hollow disc dryer and stamping method of metal plate stamping mechanism

A disc dryer and stamping mechanism technology, which is applied in the field of stamping, can solve the problems of inconvenient mold stripping, difficulty in realizing the lubrication of the ejector mechanism, and low stamping efficiency of the stamping mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

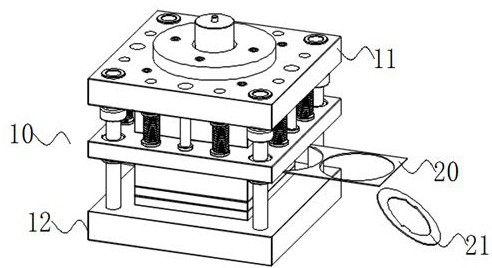

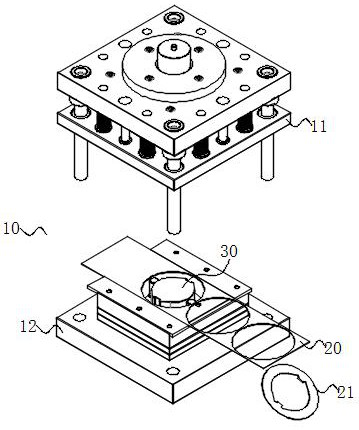

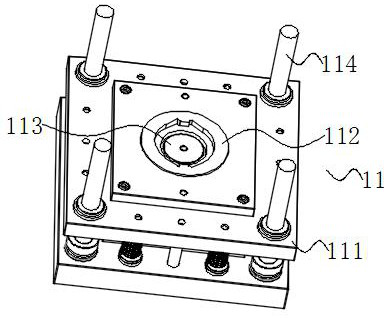

[0045] A sheet metal stamping mechanism of a hollow disc dryer, according to Figure 1-Figure 4 , Figure 11-Figure 13 As shown, a stamping assembly 10 is included, and the stamping assembly 10 includes an upper die base 11 and a lower die base 12. A plurality of hydraulic rods 114 are installed on the end of the upper die base 11 near the lower die base 12, and a plurality of hydraulic pressure rods 114 are installed. Rods 114 are equidistantly arranged around the bottom of the upper die base 11, and the upper die base 11 is slidably connected with the lower die base 12 through hydraulic rods 114. The upper die base 11 includes an upper template 111 and a die 112. Die 112 is provided at the bottom of upper template 111, and the interior of described die 112 is equipped with lubricating assembly 113, and described lower mold base 12 comprises lower template 121 and positioning plate 122, and the bottom of described positioning plate 122 is connected with lower template. The o...

Embodiment 2

[0048] A sheet metal stamping mechanism of a hollow disc dryer, according to Figure 14-Figure 16 As shown, on the basis of Embodiment 1, an adjustment hole assembly 321 is opened on the ejector block 32, and the adjustment hole assembly 321 includes a lower adjustment hole 3211 and an upper adjustment hole 3212, and the diameter of the lower adjustment hole 3211 is Greater than the diameter of the upper adjustment hole 3212, the top of the adjustment rod 311 is fixedly connected with an adjustment block 312, the diameter of the adjustment block 312 is the same as the diameter of the upper adjustment hole 3212, and the outer surface of the adjustment rod 311 is distributed with external threads. The inner surface of the lower adjustment hole 3211 is distributed with internal threads that match the external threads distributed on the outer surface of the adjustment rod 311, the ejector block 32 is rotationally connected with the base 31 through the adjustment rod 311, and the li...

Embodiment 3

[0051] A sheet metal stamping mechanism of a hollow disc dryer, according to Figure 5-Figure 10 As shown, on the basis of Embodiment 1, the right side of the positioning plate 122 is connected with a two-way threaded rod 123, and the two-way threaded rod 123 is threaded with a slide plate 1223, and the slide plate 1223 is arranged in an L shape. The inner bottom of the positioning plate 122 is provided with a groove, and the sliding plate 1223 is slidably connected with the positioning plate 122 through the groove, and the inner bottom end of the sliding plate 1223 extending to the outside of the positioning plate 122 is slidably connected with a fastening rubber block 1224 .

[0052] In this embodiment, on the basis of Embodiment 1 and Embodiment 2, the two-way threaded rod 123 is screwed. Since the slide plate 1223 inside the positioning plate 122 is threaded on the outer surface of the two-way threaded rod 123, the two-way threaded rod is rotated 123 can control the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com