A hook and loop semi-finished product dyeing and drying device

A technology for drying devices and semi-finished products, applied in drying, drying machines, heating devices, etc., can solve problems such as insufficient contact, secondary wetting of cloth, pollution, etc., to ensure contact, avoid pollution, and ensure the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

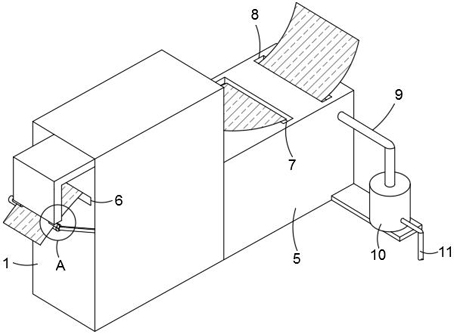

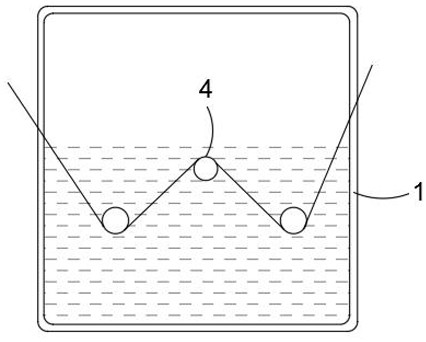

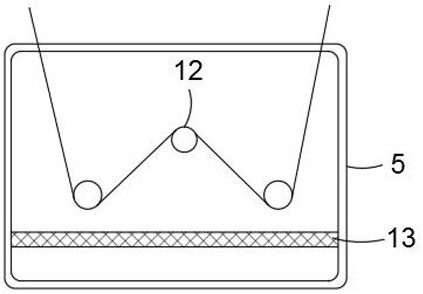

[0032] refer to Figure 1-7 , a hook and loop semi-finished product dyeing and drying device, comprising a dyeing box 1 and a drying box 5, the outer walls of both sides of the dyeing box 1 are respectively provided with a feed port 6 and a material guide port, and the upper side wall of the drying box 5 A material inlet 7 and a material outlet 8 are provided, and two installation rods 2 are fixedly connected to the outer wall of the end of the dyeing box 1, and a guide roller 3 is installed between the two installation rods 2, and the inside of the dyeing box 1 is installed with A plurality of guide rollers 2 4, a plurality of guide rollers 3 12 and a heating plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com