Quick connecting device for drill bit of anchor changing machine

A technology of quick connection and drill bit, applied in drill pipe, drill pipe, drilling equipment, etc., can solve the problems of drill bit damage, long time to pull out the drill bit, and high safety risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described now in conjunction with accompanying drawing.

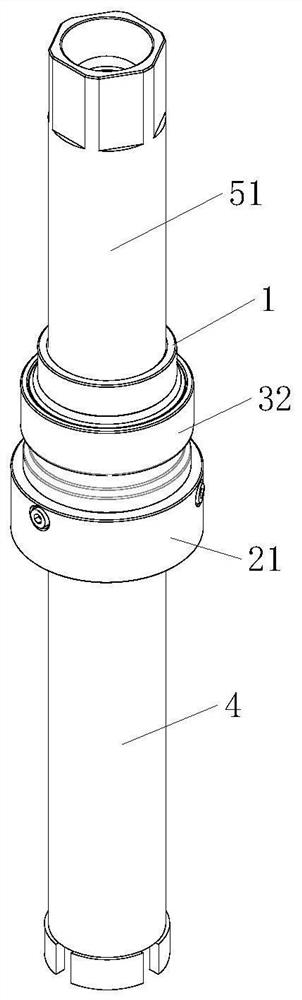

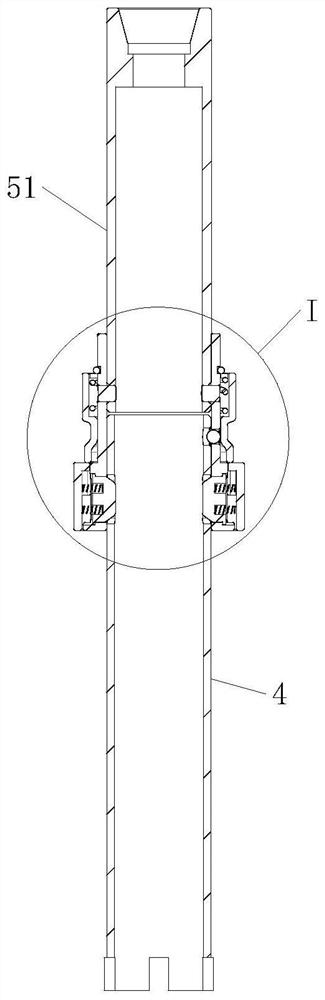

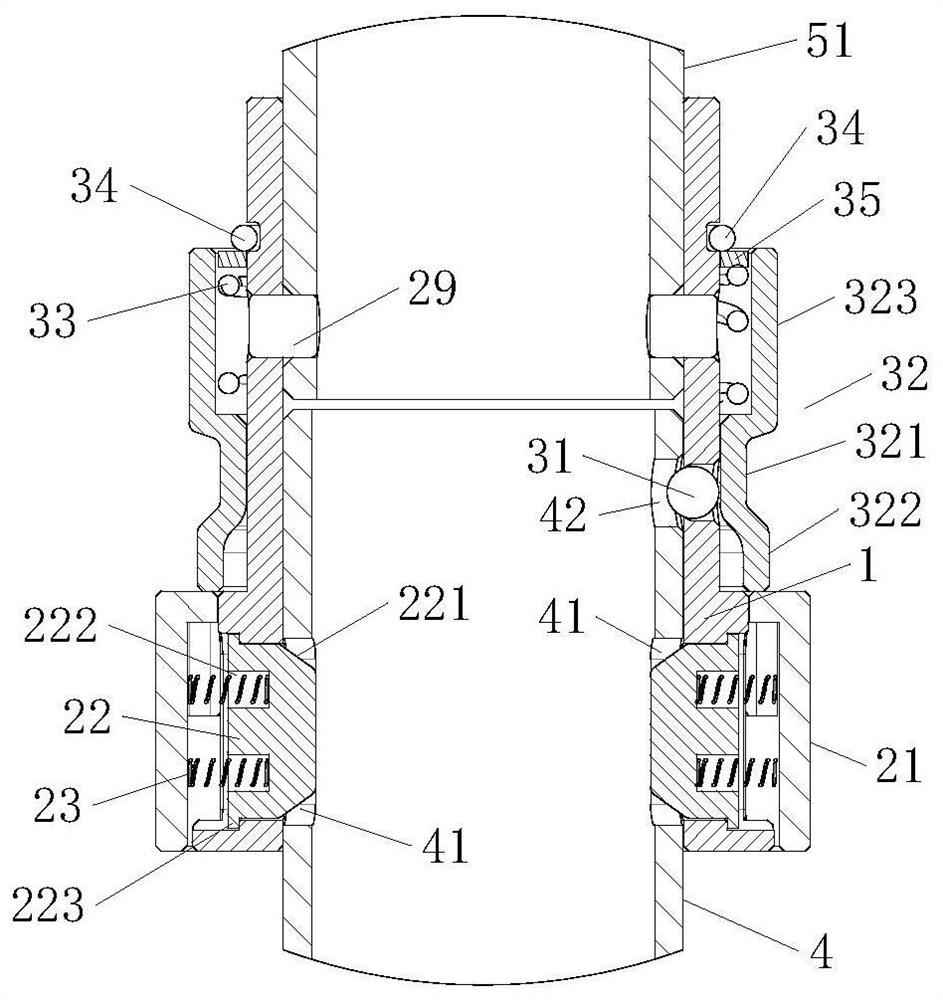

[0030] Such as Figure 1 to Figure 7 As shown, the quick connecting device for the drill bit of the anchor windlass includes a steel ball 31, a connecting seat 1, a driving block 22, a connecting sleeve 21, a driving spring 23, a locking sleeve 32 and a drill bit 4; the connecting seat 1 is installed on the connecting pipe of the windlass 51, the connecting seat 1 is provided with a fixing hole 15, a connecting hole 18, a sliding hole 12 and a locking hole 14, the connecting hole 18 is used to insert the drill bit 4, and the fixing hole 15 is connected with the connecting pipe 51 on the windlass by a pin 29, Both the sliding hole 12 and the locking hole 14 communicate with the connecting hole 18, and the steel ball 31 is movably inserted in the locking hole 14. The locking hole 14 is located at one end of the connecting hole 18 and is provided with a limiting ring 141, which ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap