Yielding supporting structure

A supporting structure and pipe pressure technology, which can be applied to shaft lining, tunnel lining, underground chamber, etc., and can solve problems such as variable resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

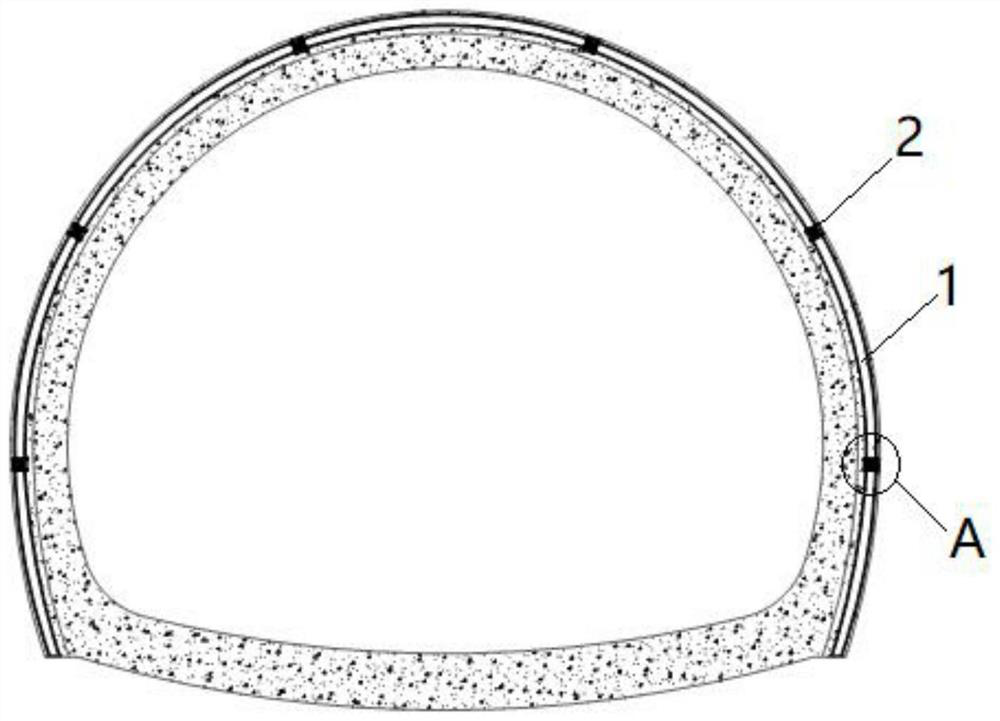

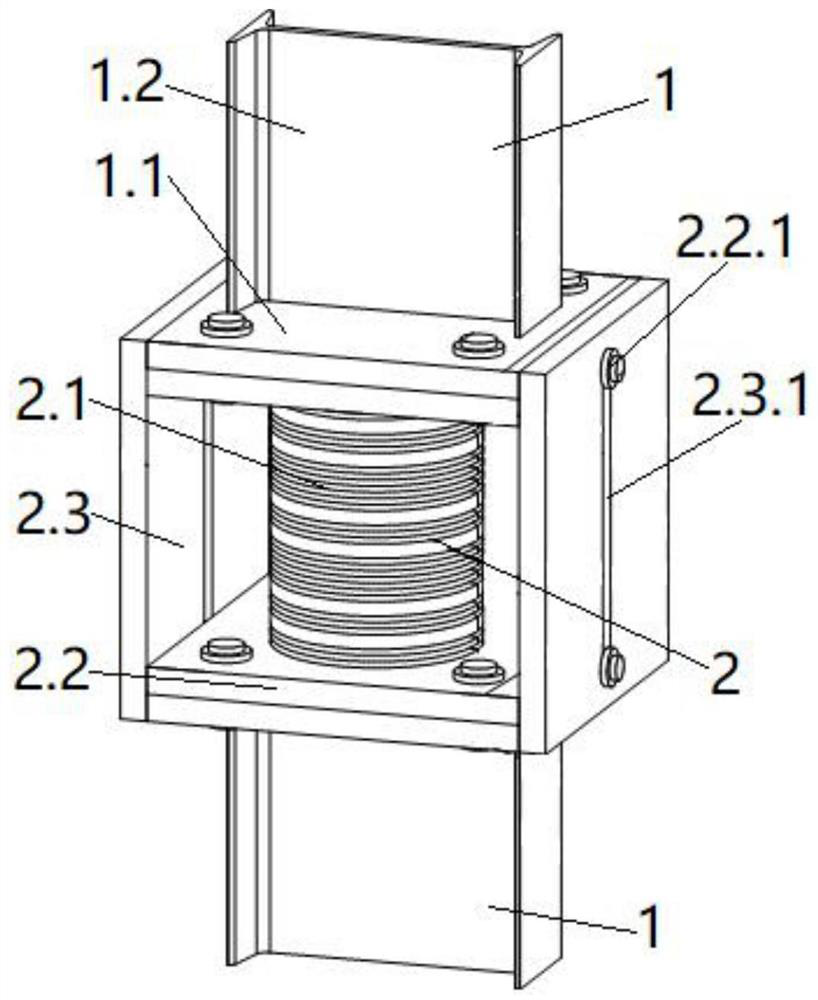

[0037] see Figure 1 to Figure 9 , a pressure yielding support structure, this embodiment is applied to the self-adaptive variable resistance pressure yielding support of large deformation tunnels.

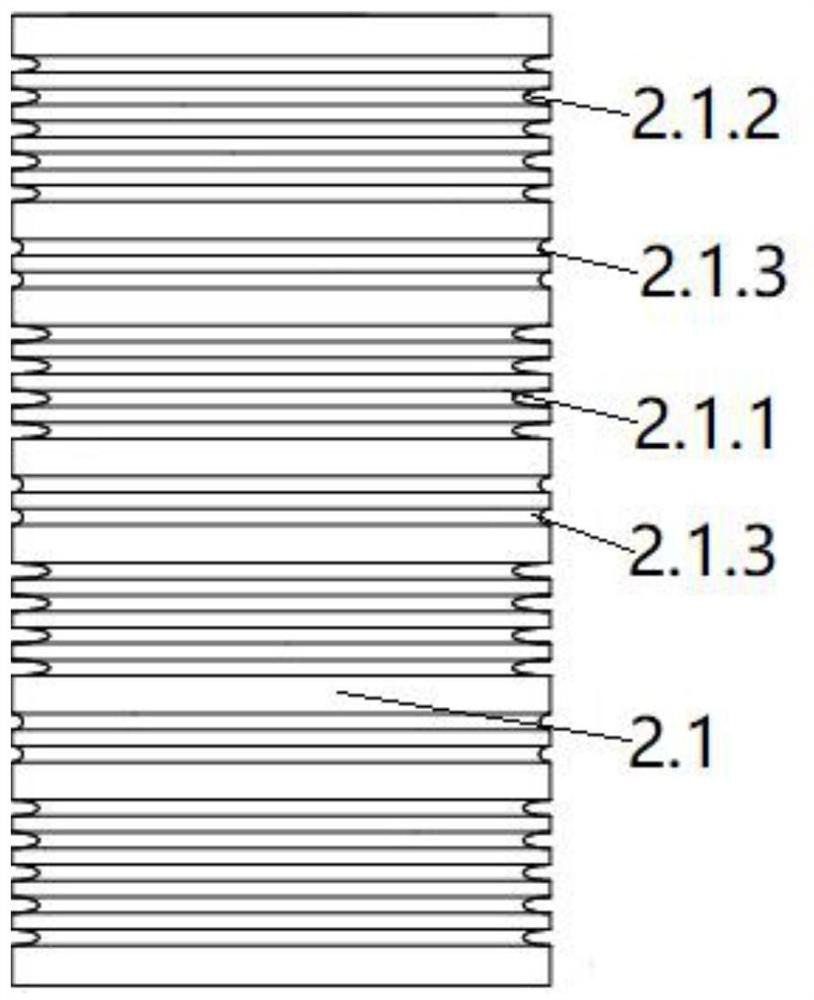

[0038] A pressure-yielding support structure, see figure 1 , including a plurality of arch units 1 and a plurality of pressure relief components 2; adjacent arch units 1 are connected by pressure relief components 2, and a plurality of arch units 1 are connected end to end to form an arc-shaped arch that matches the profile of the tunnel section ; see figure 2 with image 3, the pressure relief assembly 2 includes a pressure relief pipe 2.1, at least two dimpled areas with different concave depths are provided on the outer wall of the pressure relief pipe 2.1 along the axial direction of the pressure relief pipe 2.1; and the axis of the pressure relief pipe 2.1 The direction is parallel to the connection direction between the pressure relief assembly 2 and the arch unit 1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com