Flow guide structure for improving local high temperature of exhaust side of longitudinal engine assembly

A technology of engine assembly and local high temperature, which is applied in the direction of engine cooling, combustion engine, engine components, etc., which can solve the problems of long development cycle, high cost, overheating of exhaust side parts of engine assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

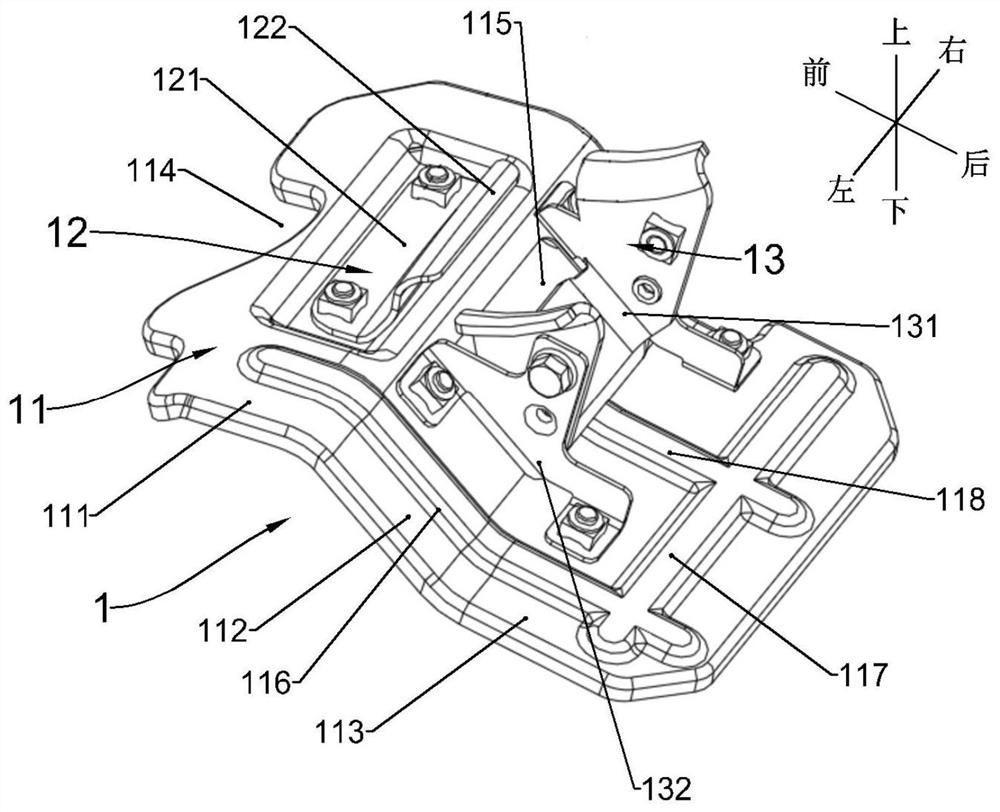

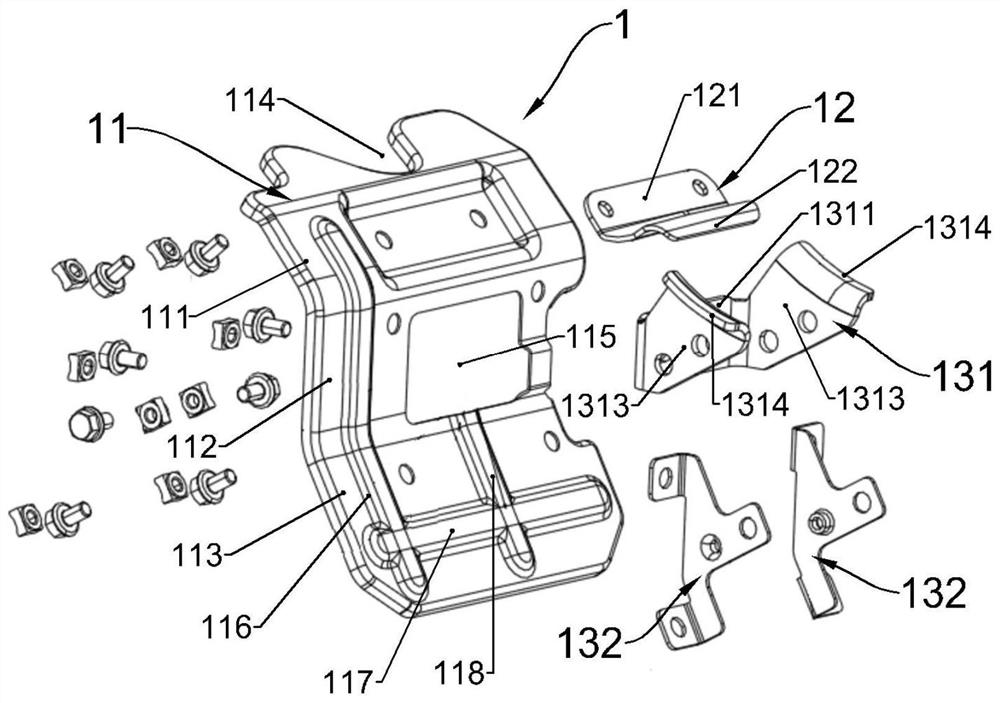

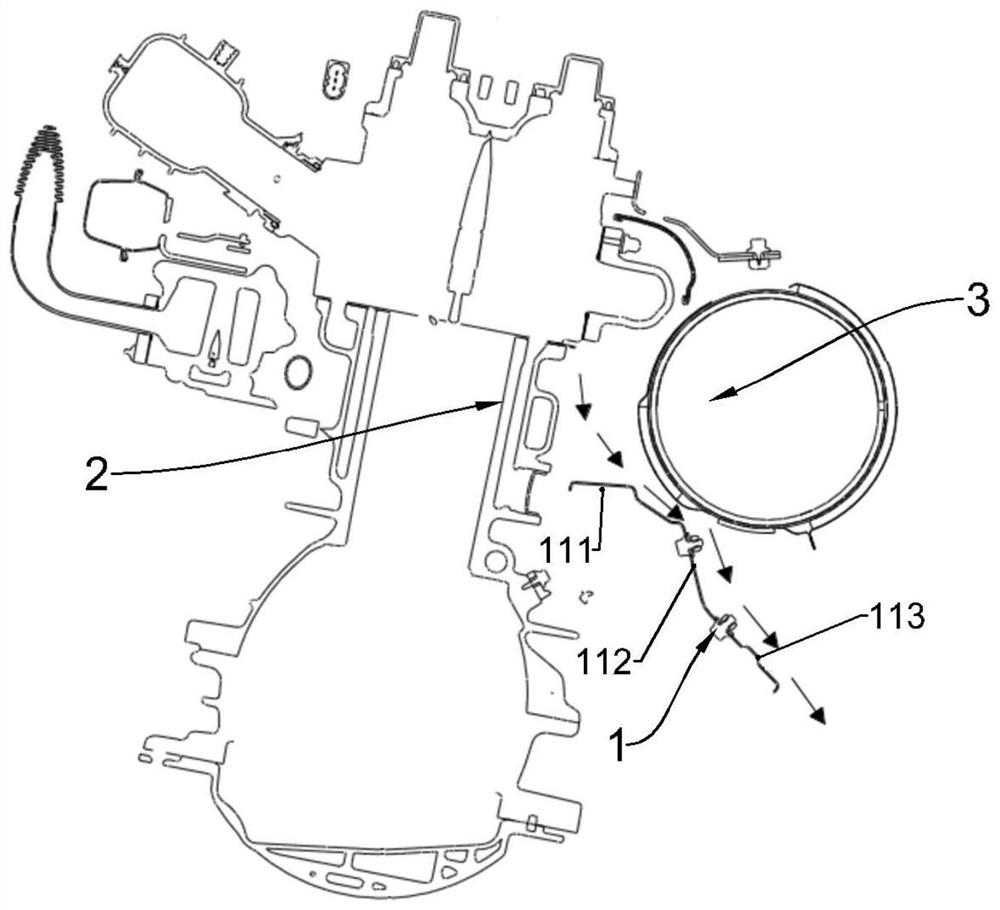

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] like Figure 1-Figure 4 As shown, in this embodiment, a flow guide structure for improving local high temperature on the exhaust side of the longitudinally mounted engine assembly includes the engine assembly 2 and the particulate filter assembly arranged on the exhaust side of the engine assembly 2 3, also includes a flow guide member 1 arranged between the engine assembly 2 and the particle trap assembly 3, the flow guide member 1 includes a deflector body 11 and an installation assembly, the flow guide body 11 is connected with the particle trap The deflector assembly 3 is connected through the installation components. The deflector main body 11 includes the front deflector section 111, the deflector middle section 112 and the deflector rear section 113 connected in sequence from front to back, the deflector front section 111, the engine assembly 2 And the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com