Magnetic coupling temperature control system and magnetic drive pump adopting same

A technology of temperature control system and magnetic coupling, which is applied to the components of pumping devices for elastic fluid, pump control, pumps, etc., can solve the problems of undeveloped research on the accuracy of temperature detection, so as to avoid overheating, demagnetization, Excellent cooling and cooling effect, avoiding local high temperature problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

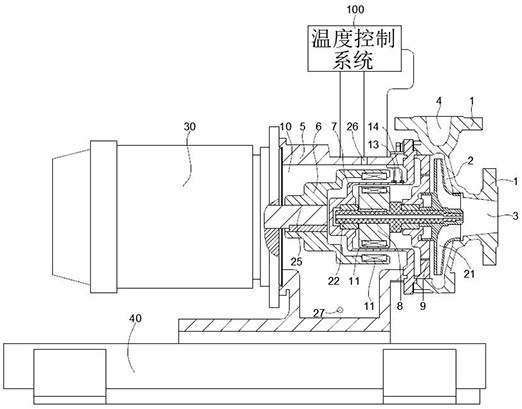

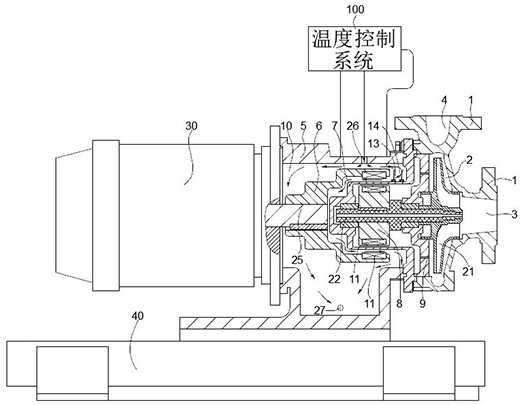

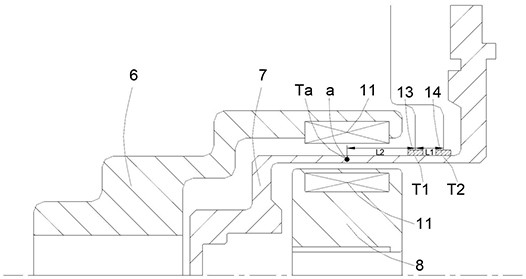

[0057] refer to figure 1 , image 3 , this embodiment provides a temperature control system for a magnetic coupling, including a magnetic coupling and a temperature control system 100;

[0058] The magnetic coupling includes an outer rotor 6, an inner rotor 8, and a metal spacer 7;

[0059] The temperature control system 100 includes a first temperature sensor 13, a second temperature sensor 14, a control module 101, and a cooling module 102. The first temperature sensor 13 and the second temperature sensor 14 are connected to the control module 101 respectively, and the control module 101 and the cooling module 102 connect;

[0060] Both the outer rotor 6 and the inner rotor 8 are provided with magnetic steel 11, the magnetic steel 11 in the outer rotor 6 is magnetically coupled with the magnetic steel 11 in the inner rotor 8, and the metal spacer 7 is arranged between the outer rotor 6 and the inner rotor 8 ;

[0061] A first temperature sensor 13 and a second temperatur...

Embodiment 2

[0079] refer to Figure 1-Figure 3 , this embodiment provides a magnetic pump using the temperature control system described in Embodiment 1, which also includes a housing assembly and a pump drive motor 30; the housing assembly includes a front pump housing 1 and a rear pump housing 5, and the bottom of the rear pump housing 5 is A base 40 is fixedly installed, and the base 40 is used to support the entire magnetic pump; the magnetic coupling is installed in the magnetic pump, and the metal spacer 7 in the magnetic coupling is fixedly arranged between the front pump casing 1 and the rear pump casing 5, The metal spacer 7 divides the internal chamber between the front pump casing 1 and the rear pump casing 5 into two mutually isolated chambers, namely the pump chamber 2 and the drive chamber 10, and the inner side of the metal spacer 7 and the pump chamber 2 connected.

[0080]The pump chamber 2 is provided with an impeller 21, and the front pump casing 1 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com