Clamping control system and method for lagging jack mounting trolley

An arch installation and control system technology, which is applied to fluid pressure actuation system components, shaft equipment, earthwork drilling and production, etc., and can solve problems such as long cycle, device vibration, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

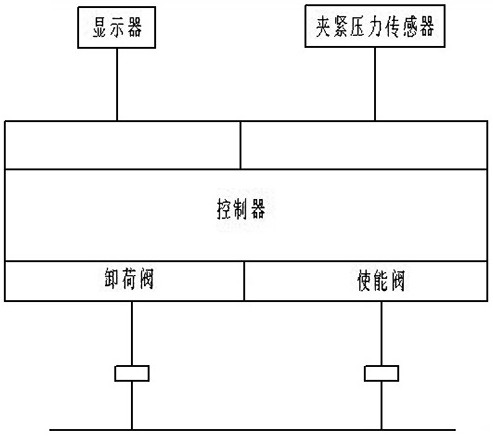

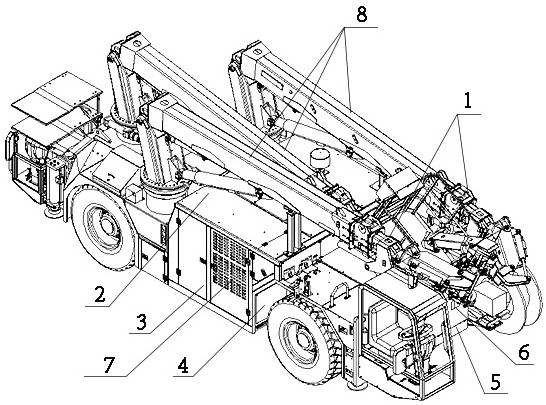

[0027] An arch installation trolley clamping control system, including a trolley, the actuator 7 of the trolley is provided with an actuator enabling valve 2 and an actuator unloading valve 4, and the actuator enabling valve 2 and The actuator unloading valves 4 are all connected with the controller 5; the arm frame 8 of the trolley is provided with a clamping device 1, and the clamping device 1 is connected with the clamping pressure sensor 3, and the clamping pressure The sensor 3 is also connected with the controller 5; a display 6 is arranged in the operating room of the trolley, and the display 6 is connected with the controller 5, and the controller 5 is arranged in the electric control cabinet of the trolley where the arch is installed .

[0028] Further, in this embodiment, the clamping pressure sensor 3 is used to detect the real-time clamping pressure of the clamping device 1 on the arm frame 8 of the trolley on which the arch is installed.

[0029] Further, in this...

Embodiment 2

[0045] In order to ensure the transmission efficiency of data, in this embodiment: a trolley clamping control system for arch installation, including a trolley, the actuator 7 of the trolley is provided with an actuator enabling valve 2 and an actuator The unloading valve 4, the actuator enable valve 2 and the actuator unloading valve 4 are all connected to the controller 5; the arm frame 8 of the trolley is provided with a clamping device 1, and the clamping device 1 It is connected with the clamping pressure sensor 3, and the clamping pressure sensor 3 is also connected with the controller 5; a display 6 is arranged in the operating room of the trolley, and the display 6 is connected with the controller 5, and the control The device 5 is arranged in the electric control cabinet of the arch frame installation trolley.

[0046] Further, in this embodiment, the clamping pressure sensor 3 is used to detect the real-time clamping pressure of the clamping device 1 on the arm frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com