Method for detecting roll core of soft package battery to enter shell

A soft-pack battery and core technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as the inability to guide the manipulator, and the accurate grasping of the quality core into the shell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Before the top-side sealing and packaging process of the soft-pack lithium battery, it is necessary to ensure that the quality of the core of the soft-pack lithium battery is qualified, to prevent the cores with tab margins and tab widths from entering the next step, and to ensure that the core is accurate. Inserting into the shell prevents damage to the lugs during the process of inserting the core into the shell, which affects the production quality.

[0069] In view of the above problems, the embodiment of the present application provides a method for detecting and entering the case of the soft-pack battery core, which can determine the quality of the core packaged into the case, and can avoid inaccurate grasping and entering the case when grabbing the core into the case. The resulting damage to the tabs improves the production quality of the pouch battery.

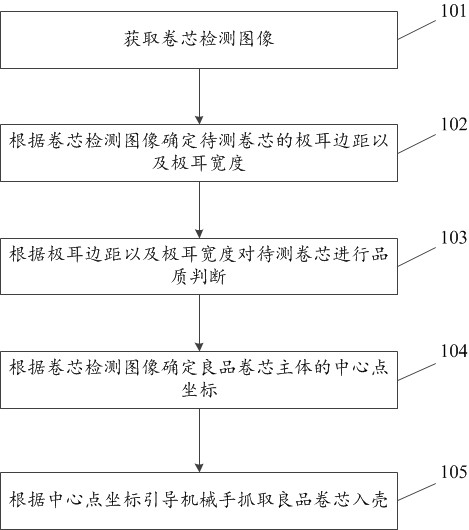

[0070] The technical solutions of the embodiments of the present application are described in detail below wi...

Embodiment 2

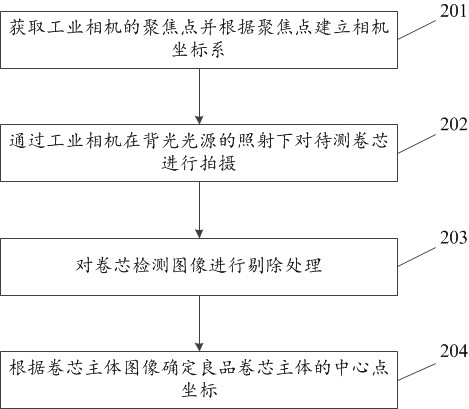

[0088] In order to facilitate understanding, an example of the method for detecting and inserting the core of the pouch battery into the case is provided below for illustration. The core is imaged by measuring the core, so that there is a significant difference in the gray value between the core to be tested and the background in the obtained core detection image. When the core to be tested is judged to be a good product, it will be determined according to the core detection image The coordinates of the center point of the core body of good product.

[0089] see figure 2 , the second embodiment of the method for detecting and inserting the core of the soft pack battery shown in the embodiment of the present application includes:

[0090] 201. Obtain the focus point of the industrial camera and establish a camera coordinate system according to the focus point;

[0091] Fix the industrial camera at a specified position, and obtain the focus point position of the industrial ca...

Embodiment 3

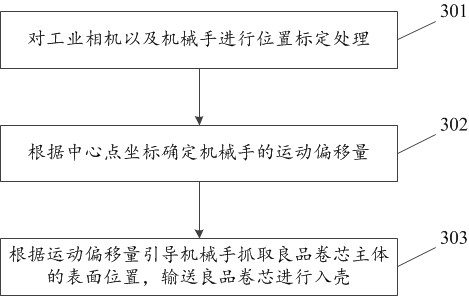

[0108] For ease of understanding, the following provides an example of a method for detecting and inserting soft-pack battery cores into the casing. In practical applications, the affine between the camera coordinate system and the base coordinate system of the manipulator will be determined through position calibration processing. Transform the matrix and the center of rotation to establish the spatial transformation relationship between the industrial camera and the manipulator, control the movement offset of the manipulator, and achieve the purpose of precise grasping and precise shell insertion.

[0109] see image 3 , the third embodiment of the method for detecting and inserting the pouch battery core into the shell shown in the embodiment of the present application includes:

[0110] 301. Perform position calibration processing on the industrial camera and the manipulator;

[0111] Control the manipulator to grab the position calibration plate to move to K preset posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com