Reversed-polarity high-power laminar plasma generator

A plasma and vortex generator technology, applied in the direction of plasma, electrical components, etc., can solve the problems affecting the continuous stability of solid waste gasification, short jet beam, and low electrode life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to explain in detail the technical solutions adopted by the present invention to achieve the intended technical purpose, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described implementation Examples are only some of the embodiments of the present invention, not all of them, and, on the premise of not paying creative work, the technical means or technical features in the embodiments of the present invention can be replaced, and the following will refer to the accompanying drawings in combination with Examples illustrate the present invention in detail.

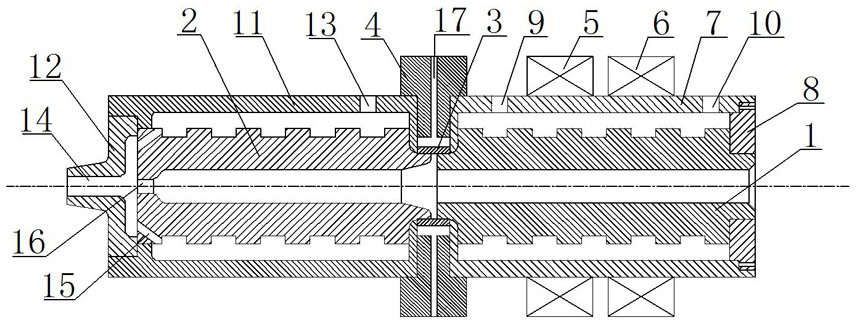

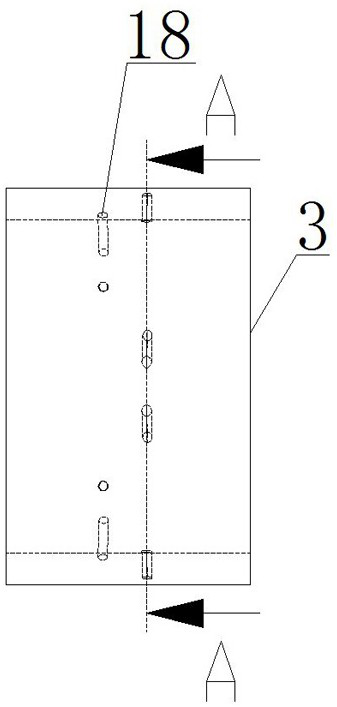

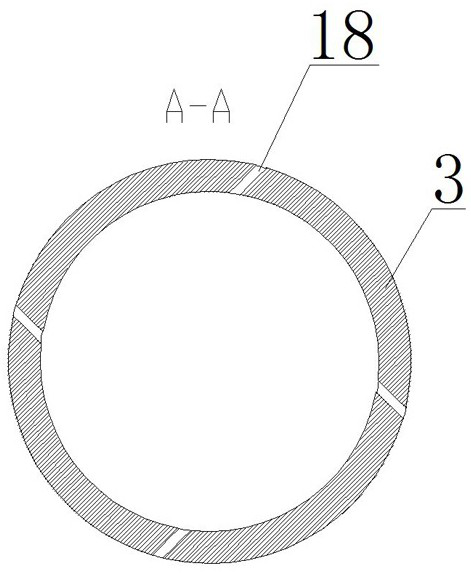

[0026] Such as figure 1 As shown, a reverse polarity high-power laminar flow plasma generator of the present invention includes a front electrode 1, a front electrode water cooling mechanism, a rear electrode 2, a rear electrode water cooling mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com