Silicone emulsion and method for producing same

A technology of silicone emulsion and silicone resin, which is applied in the field of high-concentration transparent silicone emulsion and its preparation, and can solve problems such as the stability of difficult-to-emulsify emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of silicone emulsion

[0067] The preparation method of the silicone emulsion according to the present invention comprises subjecting a nonionic surfactant to aqueous dispersion, and dividing the silicone resin mixture into components and introducing it into the aqueous dispersed nonionic surfactant eight or more times to prepare mixture.

[0068] At this time, the silicone resin mixture includes a silicone resin and a diluent, and the prepared silicone emulsion includes the silicone resin mixture and the nonionic surfactant in a weight ratio of 1:0.1 to 1:0.4. Specific examples of the silicone resin, diluent, and nonionic surfactant are the same as described above for the silicone emulsion.

[0069] Subjecting Nonionic Surfactants to Aqueous Dispersion

[0070] In this step, the nonionic surfactant is subjected to aqueous dispersion.

[0071] Specifically, in this step, a nonionic surfactant and a solvent may be mixed and subjected to aqueou...

Embodiment 1

[0085] Embodiment 1: Preparation of silicone emulsion

[0086] The components were used in the compositions described in Table 1, and the silicone resin mixture was divided and introduced under the process conditions described in Table 3.

[0087] Specifically, deionized water-1 and a nonionic surfactant were introduced into the reactor, and stirred for 30 minutes while raising the temperature to 55°C. Thereafter, while maintaining the reactor at 55° C., the silicone resin mixture was divided and introduced 15 times at intervals of 5 minutes, and then stirred at 1,000 rpm for 60 minutes. Then, deionized water-2 was added to the reactor, stirred at 1,000 rpm for 30 minutes, a preservative was added, and then stirred at 1,000 rpm for 30 minutes. After that, deionized water-3 was added to the reactor, and stirred at 1,000 rpm for 30 minutes to prepare a silicone emulsion.

Embodiment 2 to Embodiment 8 and comparative example 1 to comparative example 8

[0088] Example 2 to Example 8 and Comparative Example 1 to Comparative Example 8: Preparation of Silicone Emulsion

[0089] Silicone emulsions were prepared in the same manner as in Example 1, but the components were used with the compositions described in Table 1 and Table 2, and the silicone resin mixture was divided into components under the process conditions described in Table 3 and introduce.

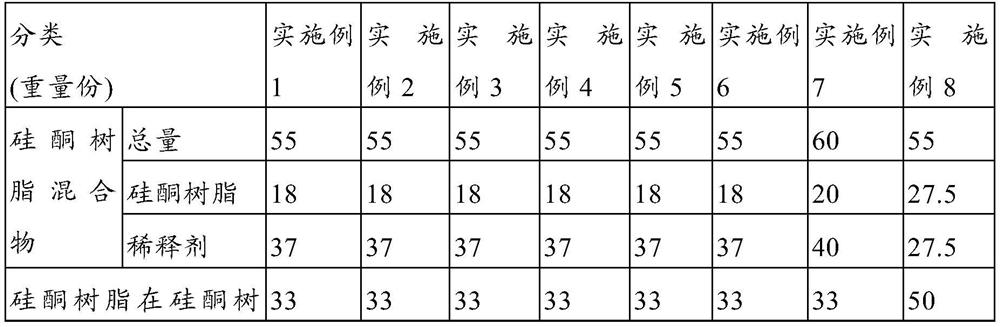

[0090] [Table 1]

[0091]

[0092]

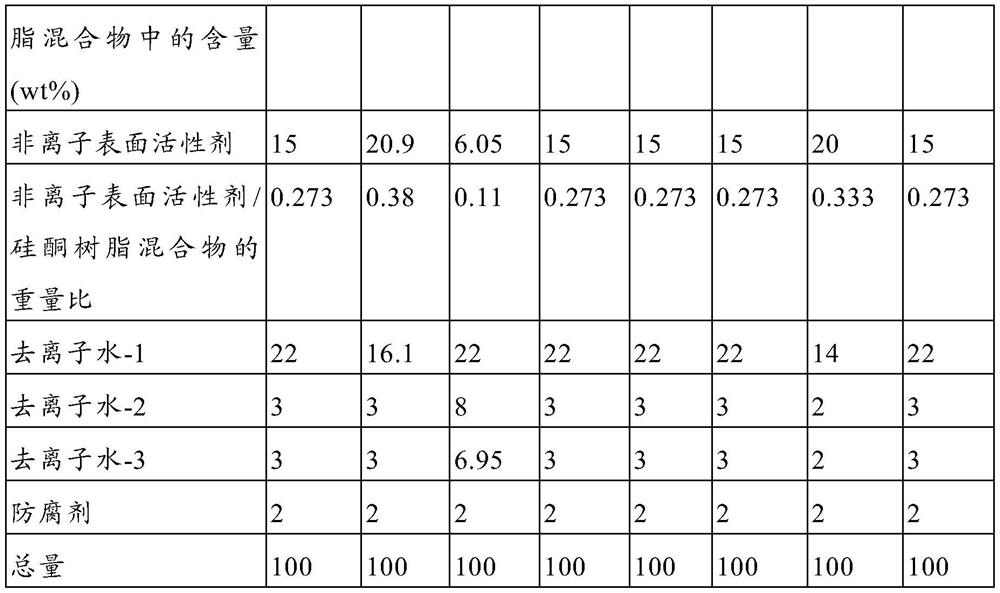

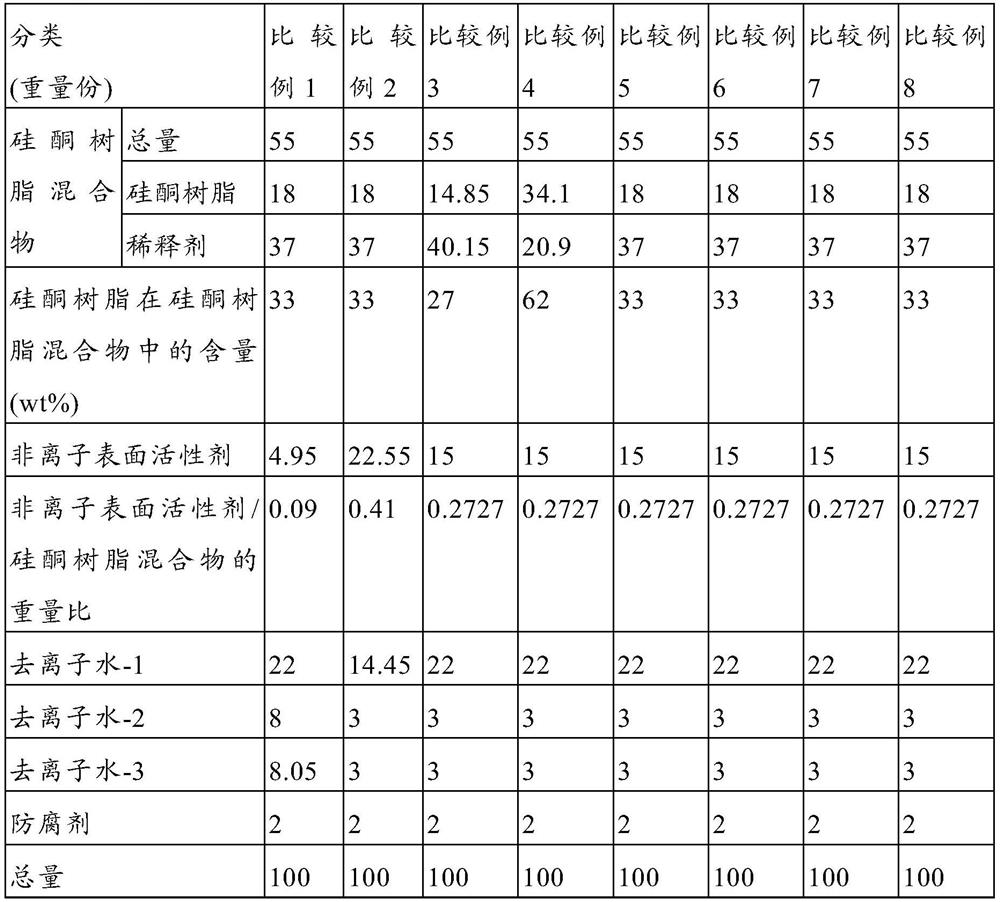

[0093] [Table 2]

[0094]

[0095] [table 3]

[0096]

[0097] The manufacturers and product names of the components used in Comparative Examples and Examples are shown in Table 4.

[0098] [Table 4]

[0099]

[0100]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com