Walnut oil microcapsule powder and preparation process of microcapsule powder

A preparation process, walnut oil technology, applied in the field of walnut oil microcapsule powder and its preparation, can solve the problems that walnut oil is easy to oxidize, cannot be subjected to high temperature treatment, and has a short shelf life, so as to improve the concentration of solids, embedding and emulsification Enhanced effect and good emulsifying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

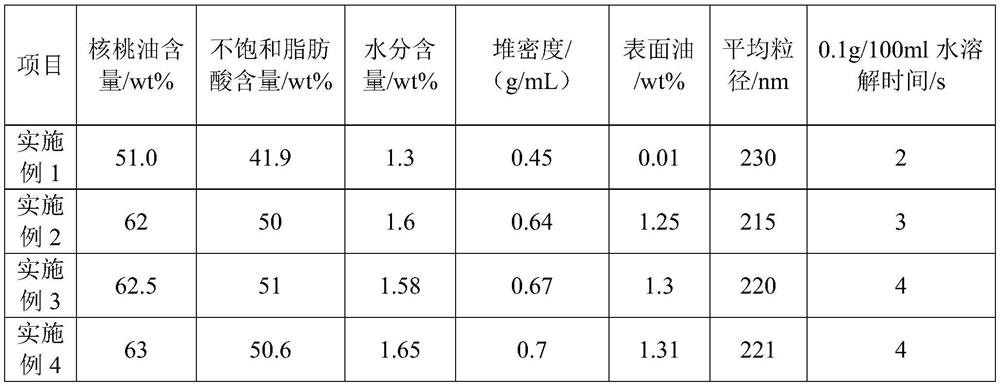

Embodiment 1

[0046] The present embodiment provides a kind of preparation technology of walnut oil microcapsule powder, and described preparation technology comprises the steps:

[0047] (1) Mix the water phase and the walnut oil core material that are dissolved with the composite wall material and auxiliary materials for shearing treatment to obtain a treatment liquid; wherein, the composite wall material is a mixture of cassava deformed starch and maltodextrin; the mixture The mass ratio of cassava modified starch and maltodextrin in the medium is 2:1; the mass percentage concentration of the composite wall material in the water phase is 40%; the auxiliary materials include walnut essence, sucralose and walnut peptide; the water phase The mass percentage concentration of the walnut essence in the water phase is 0.1%; the mass percentage concentration of the sucralose in the water phase is 0.01%; the mass percentage concentration of the walnut peptide in the water phase is 4%; the walnut o...

Embodiment 2

[0051] The present embodiment provides a kind of preparation technology of walnut oil microcapsule powder, and described preparation technology comprises the steps:

[0052] (1) Mix the water phase and the walnut oil core material that are dissolved with the composite wall material and auxiliary materials for shearing treatment to obtain a treatment liquid; wherein, the composite wall material is a mixture of cassava deformed starch and maltodextrin; the mixture The mass ratio of cassava deformed starch and maltodextrin in the water phase is 1.5:1; the mass percentage concentration of the composite wall material in the water phase is 45%; the auxiliary materials include walnut essence, sucralose and walnut peptide; the water phase The mass percentage concentration of the walnut essence in the water phase is 0.07%; the mass percentage concentration of the sucralose in the water phase is 0.02%; the mass percentage concentration of the walnut peptide in the water phase is 5%; the ...

Embodiment 3

[0056] The present embodiment provides a kind of preparation technology of walnut oil microcapsule powder, and described preparation technology comprises the steps:

[0057] (1) Mix the water phase and the walnut oil core material that are dissolved with the composite wall material and auxiliary materials for shearing treatment to obtain a treatment liquid; wherein, the composite wall material is a mixture of cassava deformed starch and maltodextrin; the mixture The mass ratio of cassava modified starch and maltodextrin in the water phase is 2.5:1; the mass percentage concentration of the composite wall material in the water phase is 35%; the auxiliary materials include walnut essence, sucralose and walnut peptide; the water phase The mass percentage concentration of the walnut essence in the water phase is 0.15%; the mass percentage concentration of the sucralose in the water phase is 0.01%; the mass percentage concentration of the walnut peptide in the water phase is 2%; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com