Fireproof coating spraying device for steel structure and spraying method of fireproof coating spraying device

A technology of fire retardant coating and spraying device, applied in the direction of spraying device, spray booth, etc., can solve the problems of single nozzle structure, fireproof coating cannot be sprayed quickly and evenly, affecting the fireproof effect of steel structure, etc., to prevent adhesion, improve The flexibility of the device, the effect of not easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

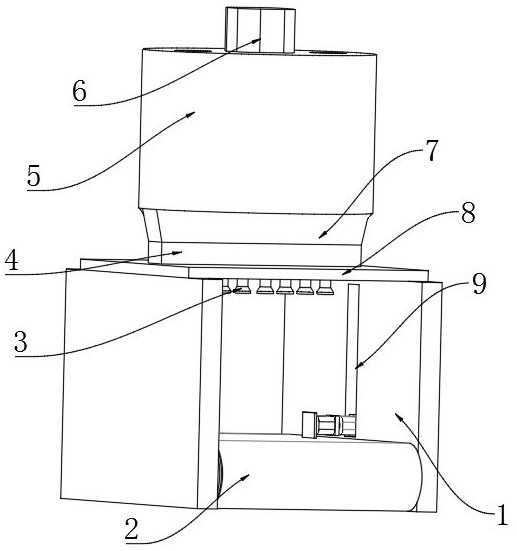

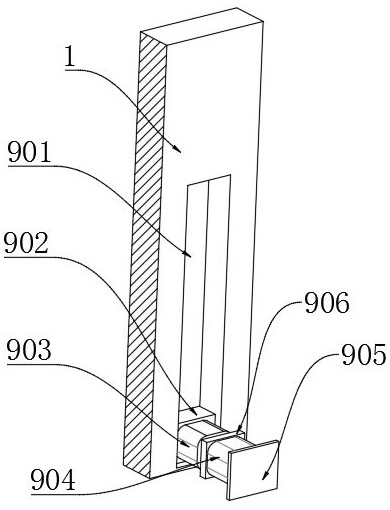

[0038] A kind of fireproof paint spraying device for steel structure, such as figure 1 As shown, it includes a spraying frame 1 and a stirring box 5; the inner wall on one side of the spraying frame 1 is provided with a conveyor belt 2; the inner wall on both sides of the spraying frame 1 is provided with a fixing mechanism 9; The outer wall at the top of the top plate 8 is fixedly connected with the electric valve box 4; the outer wall at the top of the electric valve box 4 is fixedly connected with the guide cylinder 7; Evenly distributed spraying nozzles 3 are connected; the steel structure moves on the conveyor belt 2, and the steel structure is moved to the bottom of the spraying nozzles 3 through the fixing mechanism 9. There are multiple electric valves inside the electric valve box 4, which are respectively connected with multiple spraying nozzles 3 Connected, the device speeds up the spraying of fireproof coatings on steel structures and improves work efficiency.

[00...

Embodiment 2

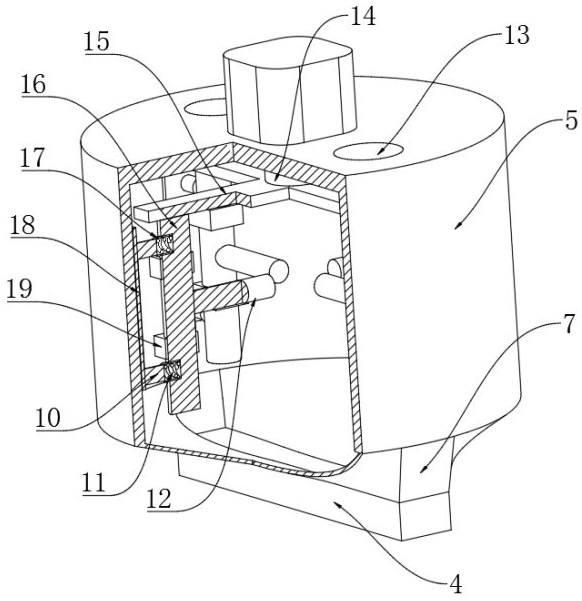

[0044] A fireproof paint spraying device for steel structures, in order to further make the device uniform when spraying steel structures, such as Figure 5 As shown, this embodiment makes the following additions on the basis of Embodiment 1: the outer wall of the top of the nozzle base 304 is fixedly connected with a hollow base 311; the inner wall of the bottom of the hollow base 311 is fixedly connected with a telescopic spring 312; the telescopic spring 312 A telescopic link 313 is fixedly connected to the top outer wall; the outer wall around the telescopic link 313 is slidably connected to the inner wall of one side of the hollow base 311 .

[0045] In order to make the fireproof coating rotate and spray inside the spray nozzle 3, as Figure 5 As shown, the outer wall of the top end of the telescopic connecting rod 313 is rotatably connected with a blocking ball 314; the diameter of the blocking ball 314 is greater than the inner diameter of the outlet cylinder 301; cyl...

Embodiment 3

[0048] A fireproof paint spraying device for steel structures, in order to enable the device to realize the function of instant start-up and stop-off function, such as Figure 6 , Figure 7 As shown, this embodiment makes the following improvements on the basis of Embodiment 2: the inner wall of the bottom end of the nozzle base 304 is fixedly connected with the electric telescopic rod 321 by screws; The telescopic rod 321 is electrically connected with the internal control unit; the gap between the ball 314 and the outlet cylinder 301 is controlled by the electric telescopic rod 321. When the electric valve inside the electric valve box 4 stops operating, there is a fireproof paint inside the outlet cylinder 301. And the operation of the electric telescopic rod 321 will block the export tube 301 by blocking the ball 314, so that the fireproof coating inside the export tube 301 cannot overflow, and realize the instant function of the device, that is, stop when it is closed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com