Movable paint spraying room

A spray booth and mobile technology, which is applied in spray booths, spray devices, fire rescue, etc., can solve the problems that cannot meet the needs of spraying high-demand items or products, poor ambient air in the spray booth, and affect production efficiency. Effects of limited use, improved aesthetics, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

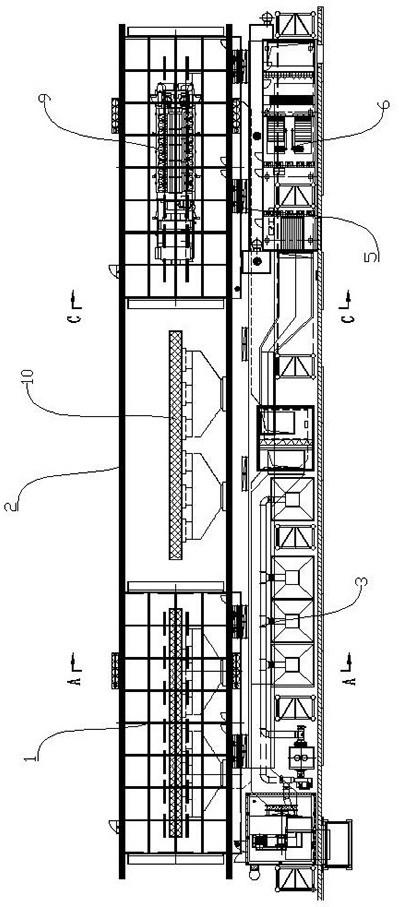

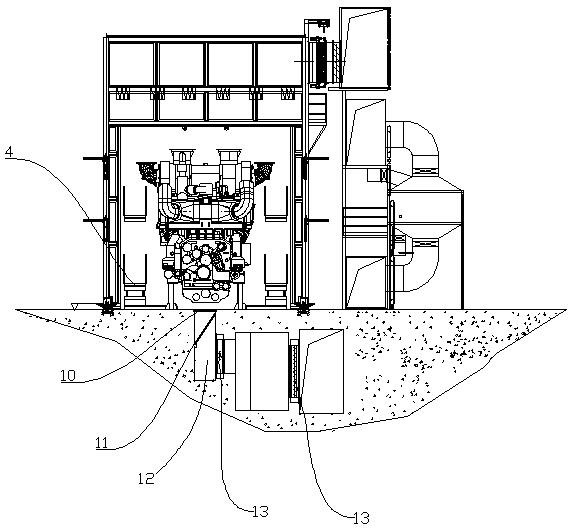

[0026] The embodiment of the present invention includes a spray booth main body 1, an exhaust gas treatment system 3, a mobile lifting platform 4, an air supply system 6, a traveling drive mechanism 7, an electrical control system and a fire extinguishing system.

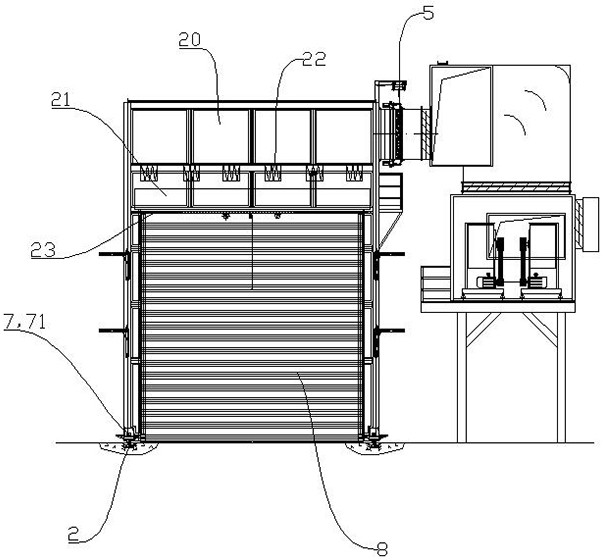

[0027] The upper part of the spray booth main body 1 adopts a double-layer structure, which is divided into a dynamic pressure chamber 20 and a static pressure chamber 21; an air distributor 22 is arranged between the dynamic pressure chamber 20 and the static pressure chamber 21, and there are multiple air distributors 22, and Evenly distributed; the upper end of the dynamic pressure chamber 20 is provided with an air duct butt joint device 5, the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com