Sports cover combination machine

A combined machine and moving cover technology, applied in the field of combined machines, can solve the problems of machine stuck, reduced production efficiency and product quality, damage to the main engine, etc., and achieves the effect of convenient separation from the screening mechanism, easy picking, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

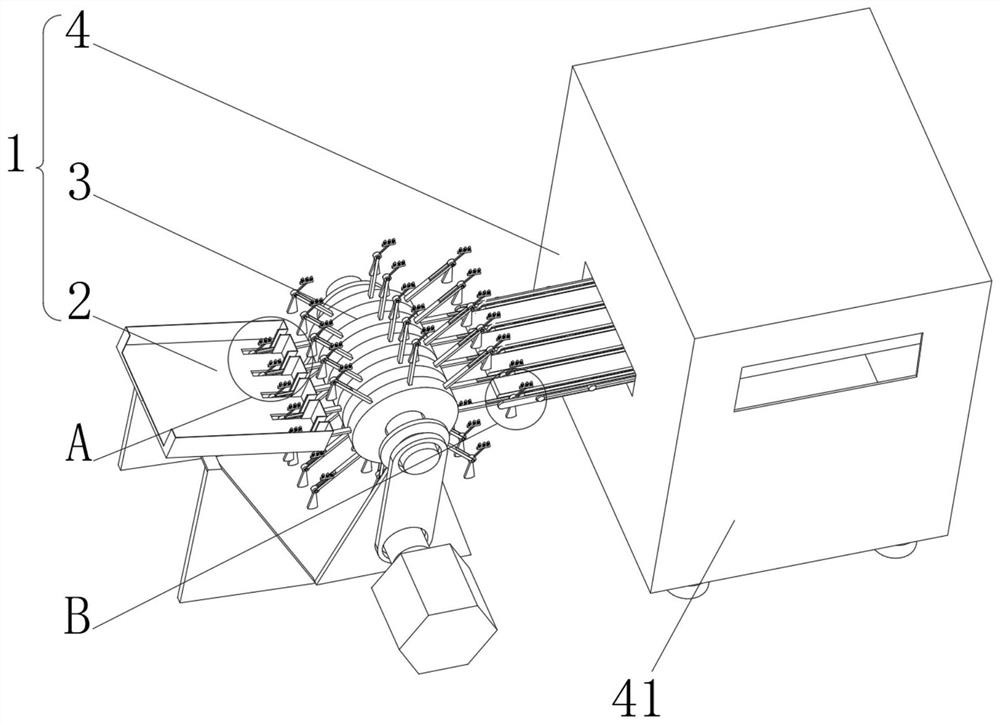

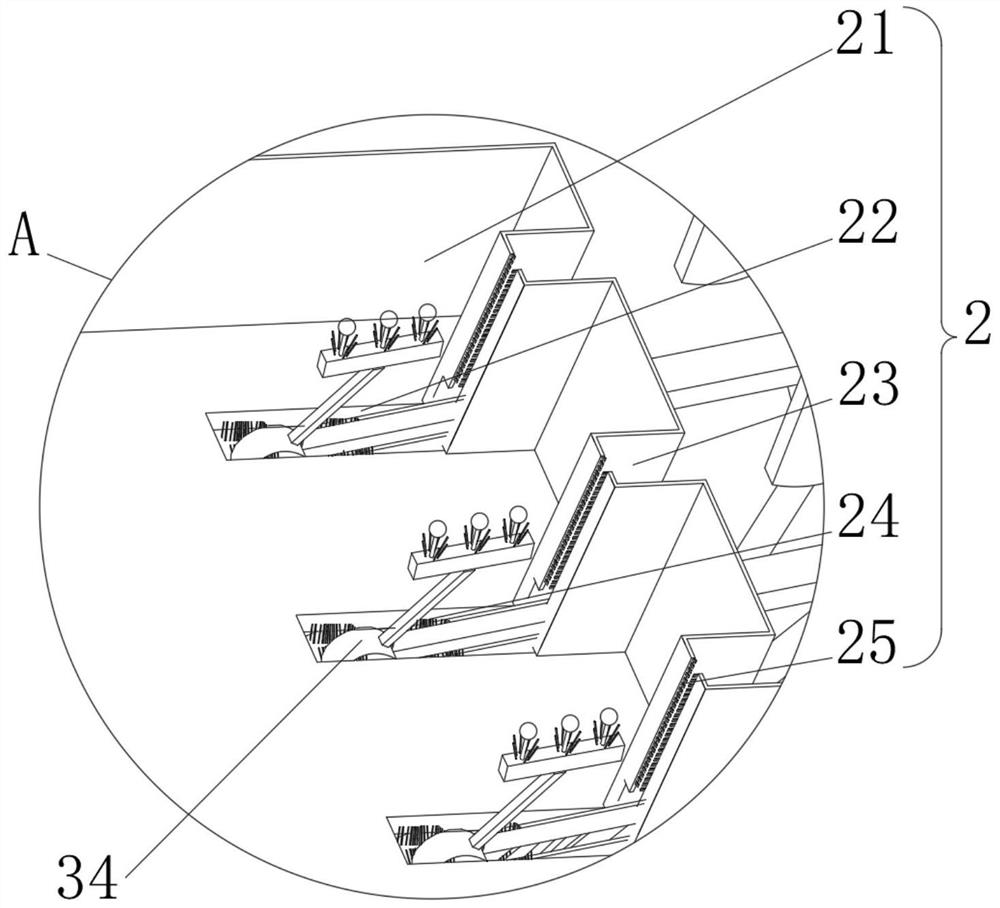

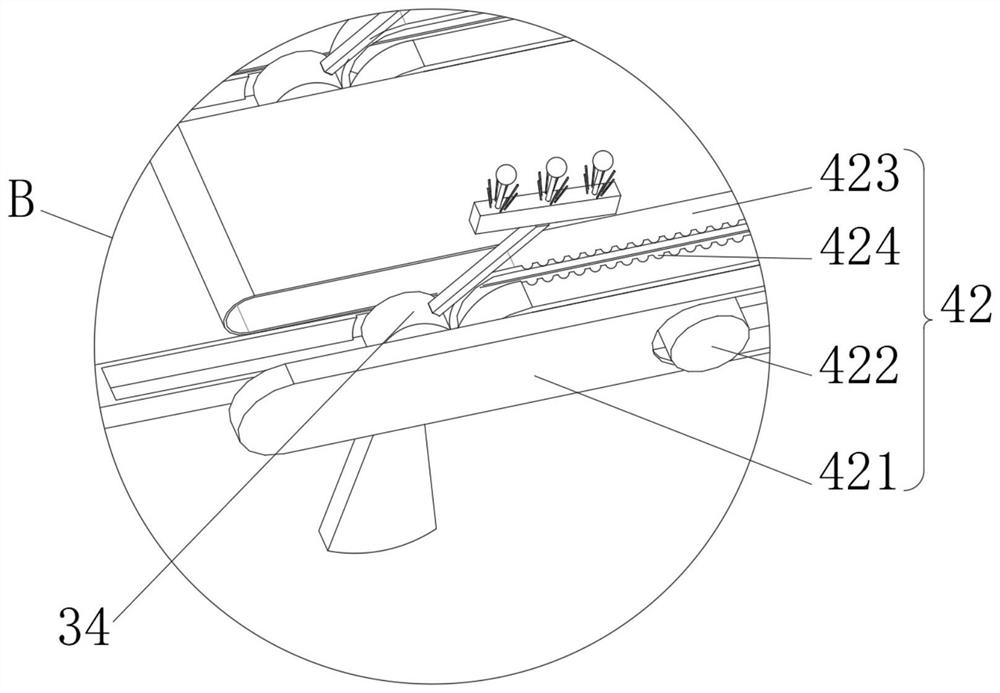

[0041] see Figure 1-7 , the present invention provides a technical solution: a moving cover assembly machine, comprising a moving cover assembly machine body 1 composed of a feeding mechanism 2, a screening mechanism 3 and a combination mechanism 4, the feeding mechanism 2 includes a feeding tray 21, The bottom of the tray 21 is fixedly connected with a support frame, the screening mechanism 3 is located on the right side of the feeding tray 21, the interior of the screening mechanism 3 is rotatably connected with a fixed frame through a rotating shaft, and the outer side of the screening mechanism 3 is rotatably connected with an external motor through a belt set, The combination mechanism 4 includes a combination box 41. The combination box 41 is provided with a conveying mechanism 42. The conveying mechanism 42 is located on the right side of the screening mechanism 3. The inside of the feeding tray 21 is respectively provided with a screening port 22 and a sliding groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com