Automatic unwinding, tape connecting and deviation rectifying device

A deviation correction device and automatic technology, applied in the direction of coiling strips, transportation and packaging, thin material processing, etc., can solve the problem of coil and rack deviation, affecting battery quality, poor unwinding accuracy and stability of pole pieces, etc. problems, to improve processing efficiency, ensure quality, improve unwinding accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

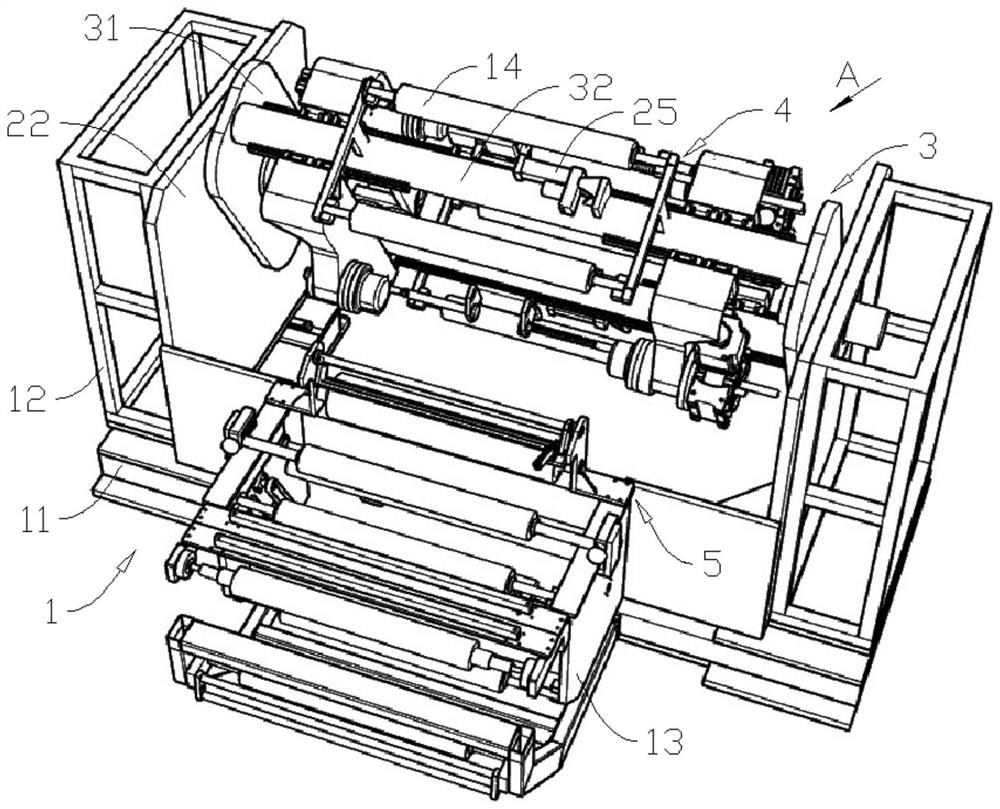

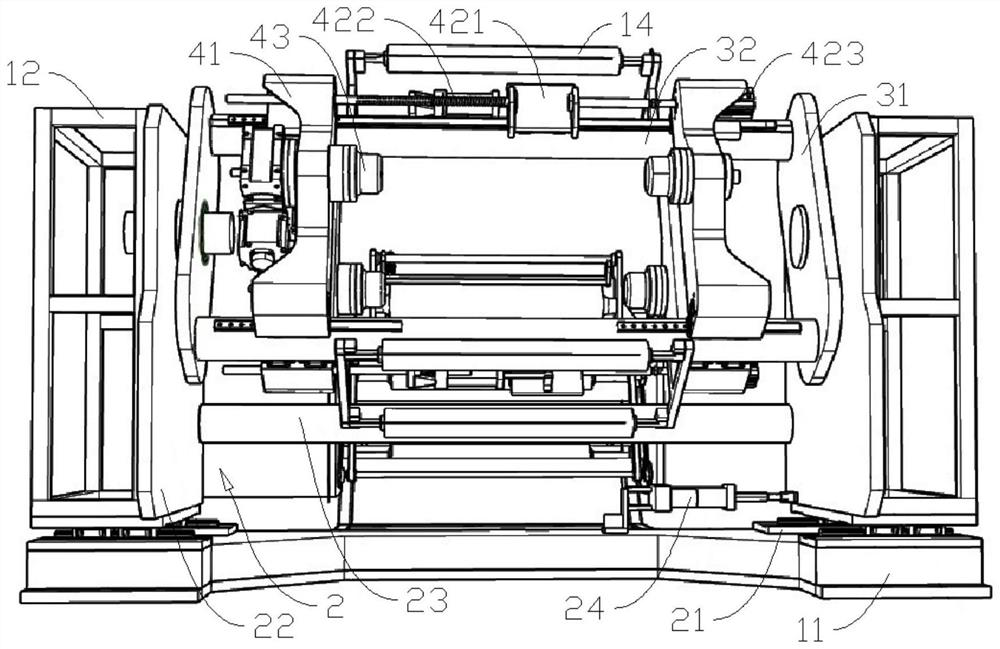

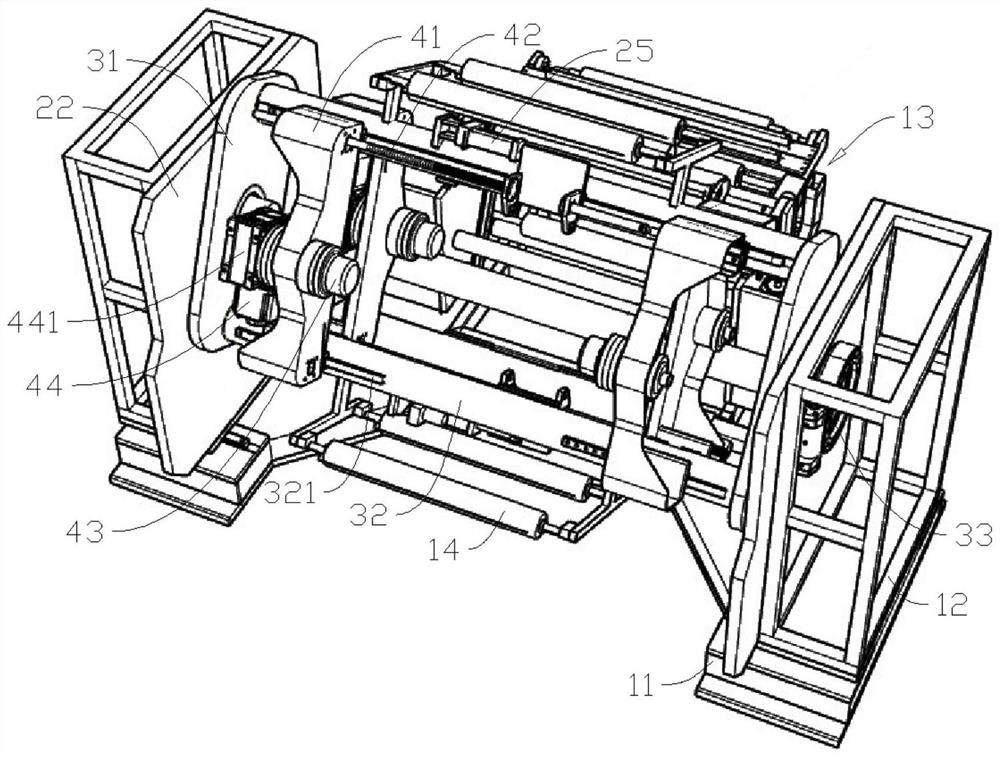

[0046] The following is attached Figure 1-6 The application is described in further detail.

[0047] The embodiment of the application discloses an automatic unwinding and splicing tape deviation correction device. refer to figure 1 , figure 2 The automatic unwinding and splicing correction device includes a frame 1, a correction component 2, a roll change component 3, a clamping component 4, and a cutting mechanism 5. The frame 1 includes a base 11, an unwinding frame 12, and a discharge frame 13. The base 11 All fixedly installed on the ground with discharging frame 13. The unwinding frame 12 is arranged on the base 11 , and a plurality of guide rollers 14 are rotatably connected to the unwinding frame 12 and the discharge frame 13 , and the rotation axis of the guide rollers 14 is perpendicular to the transmission direction of the pole piece 61 .

[0048] refer to figure 2 , The deviation correction assembly 2 includes a sliding block 21 , a vertical plate 22 , a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com