Steel-concrete-wood combined beam

A technology of composite beams and wooden beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems that the flammability of wood is easily affected by adverse environments, there are many construction procedures for on-site pouring, and the steel structure is heat-resistant and not fire-resistant. The prefabrication process is simple and easy, the economic benefits are outstanding, and the effect of good bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

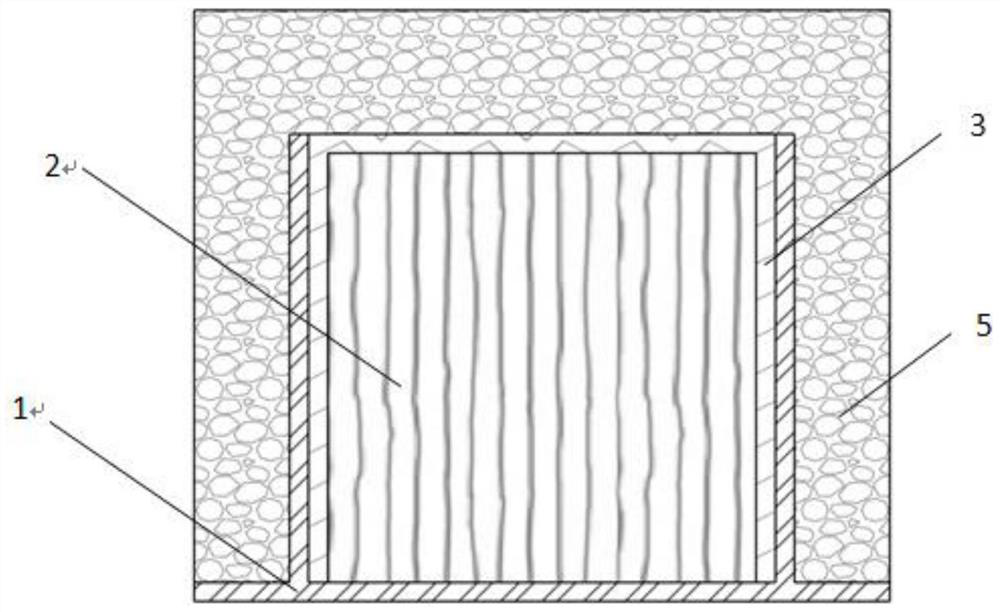

[0025] see figure 1 , a steel-concrete-wood composite beam, comprising an inverted Π-shaped steel 1, a wooden beam 2 is arranged inside the inverted Π-shaped steel 1, a thin-walled profiled steel plate 3 is arranged between the wooden beam 2 and the inverted Π-shaped steel 1, and the concrete 5 pouring on the outside of inverted Π-shaped steel 1, wooden beam 2 and thin-walled profiled steel plate 3.

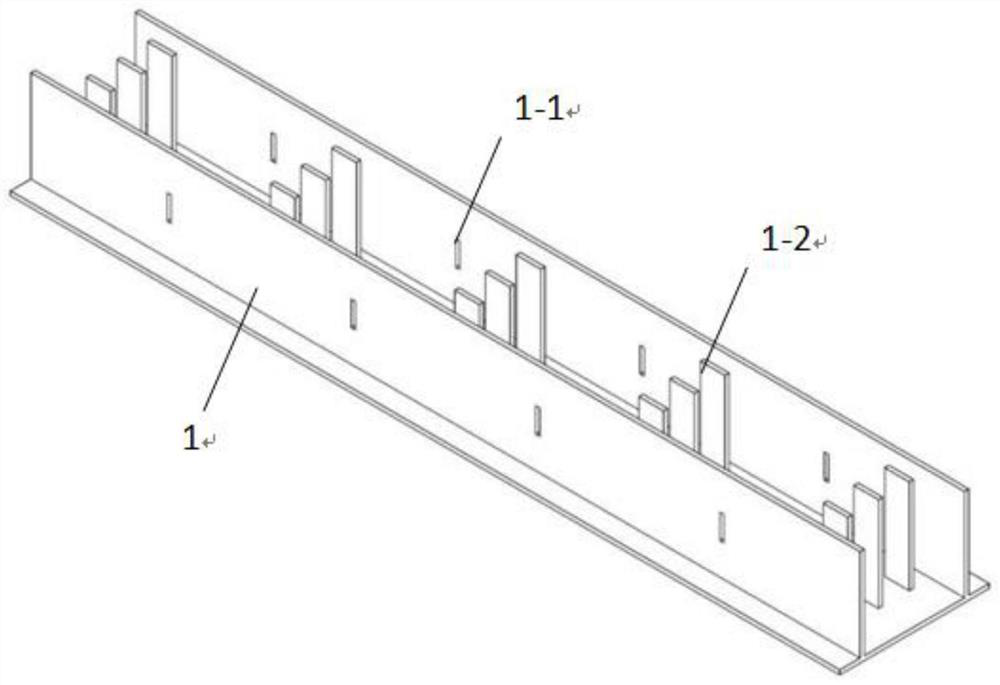

[0026] see figure 2 , the inner bottom wall of the inverted Π-shaped steel 1 is equidistantly provided with anchor pile groups 1-2, and the first nail insertion holes are arranged symmetrically between adjacent anchor pile groups 1-2 and on the flange plates on both sides of the inverted Π-shaped steel 1 1-1.

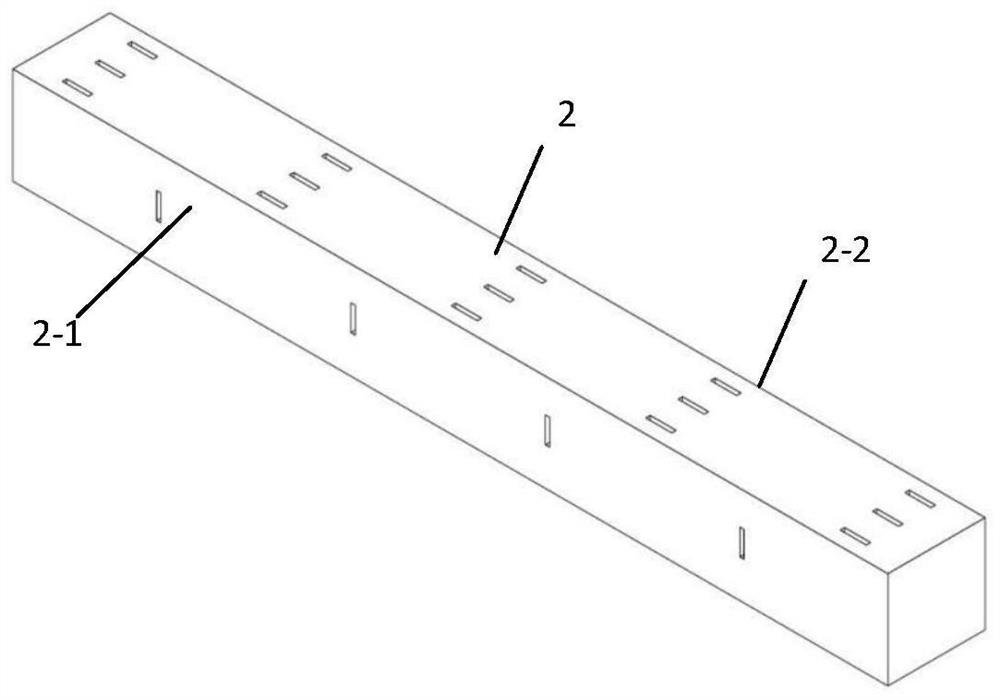

[0027] see image 3 , the wooden beam 2 is longitudinally provided with an anchor pile hole 2-2, and the anchor pile hole 2-2 is adapted to be connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com