Method for in-furnace leakage detection and non-disturbance leakage stoppage in operation state of boiler economizer

A technology of running state and plugging method, which is applied in the direction of combustion method, fuel burned in melting state, instruments, etc., can solve problems such as economizer tube panel leakage, and achieve the goal of avoiding unplanned parking, high accuracy, and reducing losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Economizer tube panels leakage occurs circulating fluidized bed boiler operating state of the embodiment according to the present embodiment, to complete the online leak detection economizer tube panel by the following process, plugging process comprises the steps of:

[0029] Operating state (1) of the circulating fluidized bed boiler economizer leak

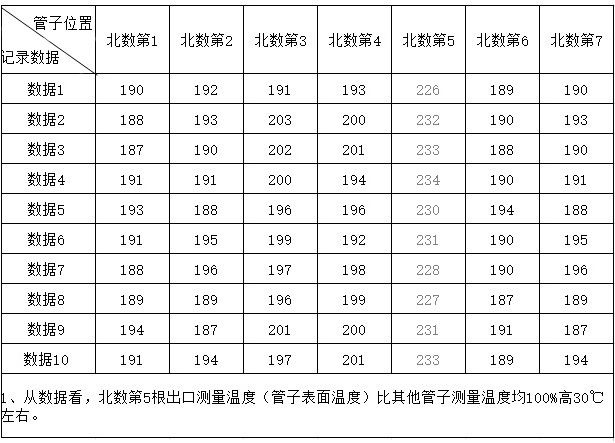

[0030] ① real-time acquisition by the thermometer of the temperature of the economizer, the collected information is transmitted to the DCS processor, the processor determines the temperature region A DCS are different, then the area A leak is determined preliminarily, and the area of the leak to the display unit (specifically a display);

[0031] ② poke out through the tamping region A wet ash, again determining the position of the leak, header shield tube panel at a region A removal step ① determined economizer header of the stem portion of the tube in the area number, the present embodiment Example A conduit region 116 ...

Embodiment 2

[0045] Example embodiment differs from embodiment 1 in that: increased humidity test.

[0046] It should be noted: Pressure Seal technology using conventional techniques in the art can; DCS using the processor, and the acquisition unit (thermometer, hygrometer), connection to the monitor using conventional techniques in the art, not here then repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com