Method and device for detecting state and fault diagnosis of radial reactor of moving bed by using acoustic emission

An acoustic emission sensor and moving bed technology, which is applied in the direction of material analysis, chemical instruments and methods, and measuring devices using acoustic emission technology, can solve the problem of not being able to determine whether there is a cavity or a wall in the reactor, and achieve long-term maintenance. The effect of stable operation, simple and easy installation, and timely fault monitoring and diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

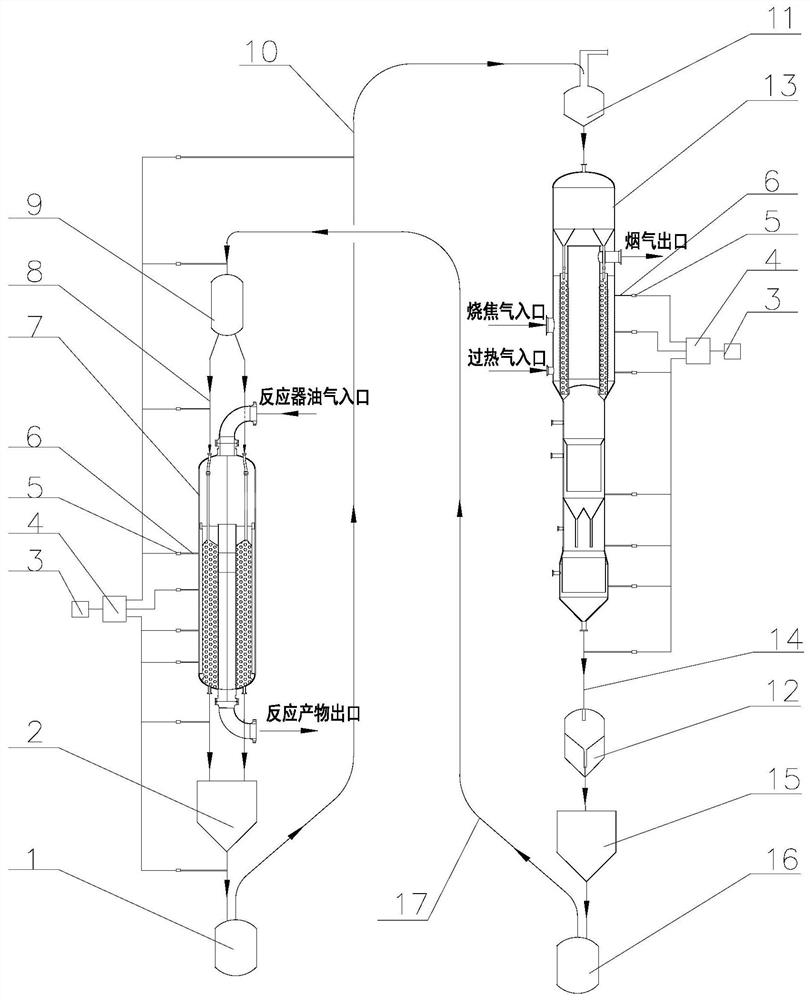

[0046] The operating state of the acoustic emission detection reactor provided in this embodiment and the fault diagnosis system (device) refer to figure 1 shown by figure 1 The fault diagnosis system shown detects the mutual motion state of gas and catalyst particles in the moving bed radial reactor, and performs acoustic emission signal collection and fault diagnosis of the continuous reforming unit. In this embodiment, the continuous reforming unit has four moving bed radial reactors with different diameters and one moving bed regenerator, wherein the inner diameter of the first reactor is 2500 mm, and the average particle size of the catalytic reforming catalyst is 1.5 mm. figure 1 Only one of the moving bed radial reactors and regenerators and the flow diagram of the catalyst circulation system are shown in .

[0047] In the acoustic emission detection reactor operating status and fault diagnosis system, the oil and gas from the heating furnace enters the reactor 7 from ...

Embodiment 2

[0056] This embodiment provides a method for fault diagnosis of a moving bed hydrocarbon dehydrogenation device by using acoustic emission, and detects the state of mutual movement of gas and catalyst particles in a moving bed radial reactor. Using the same acoustic emission fault diagnosis system as in Example 1, acoustic emission sensors were installed on the outer wall and internal components of the moving bed hydrocarbon dehydrogenation device. If necessary, a waveguide rod can be added, and an acoustic emission sensor can be arranged at one end of the waveguide rod.

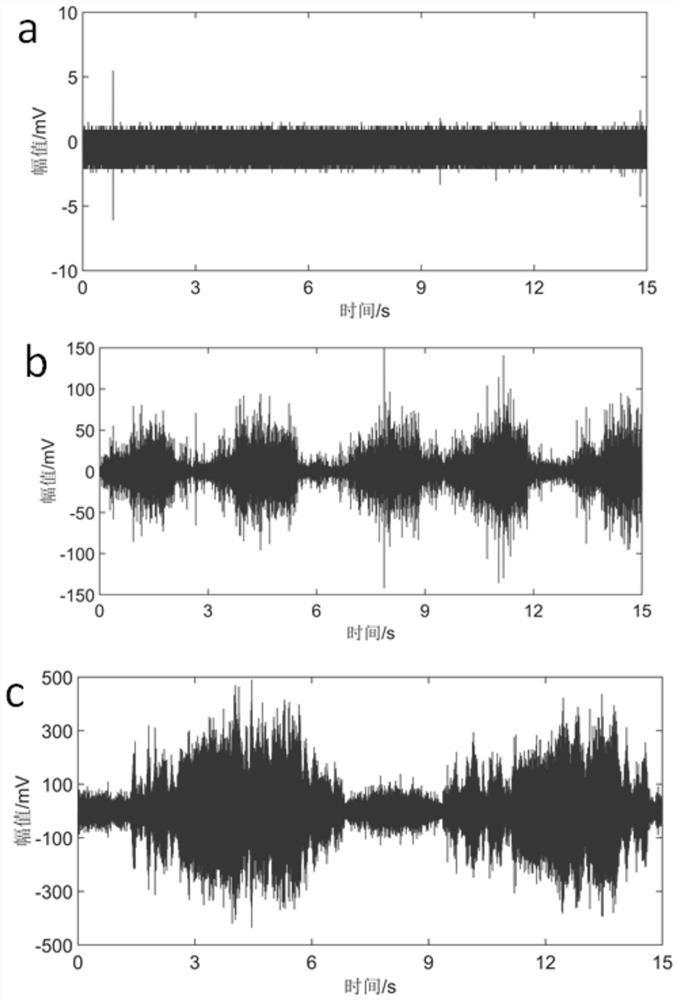

[0057] The sampling time of the acoustic emission signal acquisition system is set to 15s, and the sampling frequency is 1MHz to collect the acoustic wave signal on the outer wall of the moving bed hydrocarbon dehydrogenation reactor. Turn on the signal processing system, analyze the ASL, energy, absolute energy, impact number and other parameters of the acoustic emission signal of the moving bed hydrocarbon...

Embodiment 3

[0059] This embodiment provides a method for fault diagnosis of a moving bed aromatization process device by using acoustic emission. In this example, the aromatization process device has two moving bed radial reactors with different diameters. Acoustic emission sensors are installed on the outer wall surface of the radial reactor of the moving bed and at different axial and circumferential positions of the internal components, and are connected to the signal amplification acquisition and processing system.

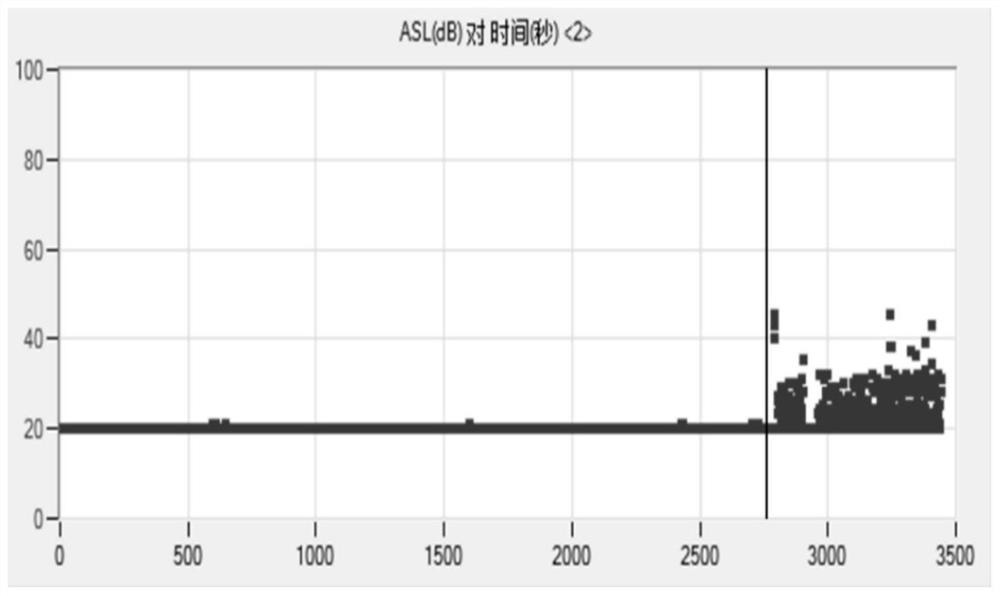

[0060] The sampling time of the acoustic emission signal acquisition system is set to 15s, and the sampling frequency is 1MHz to collect the acoustic wave signal on the outer wall of the moving bed hydrocarbon dehydrogenation reactor. Turn on the signal processing system, analyze the ASL, energy, absolute energy, impact number and other parameters of the acoustic emission signal of the moving bed hydrocarbon dehydrogenation reactor, and analyze the power spectrum of the aco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com