Accurate mycobacterium tuberculosis detection system

A tubercle bacillus and detection system technology, applied in the field of precise tuberculosis detection system, can solve the problems of reducing the contact area between glass slides and ethanol solution, low practicability, and not easy to separate, so as to improve practicability and flexibility , Degreasing effect is good, the effect of improving flexibility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

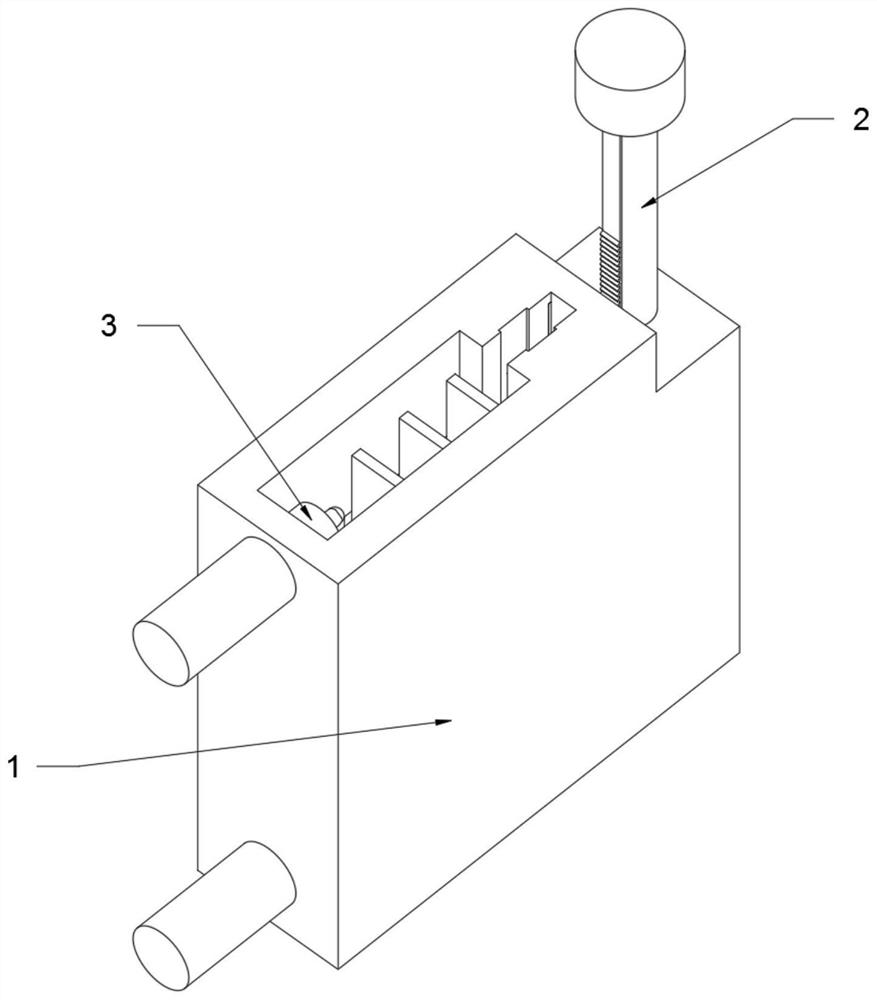

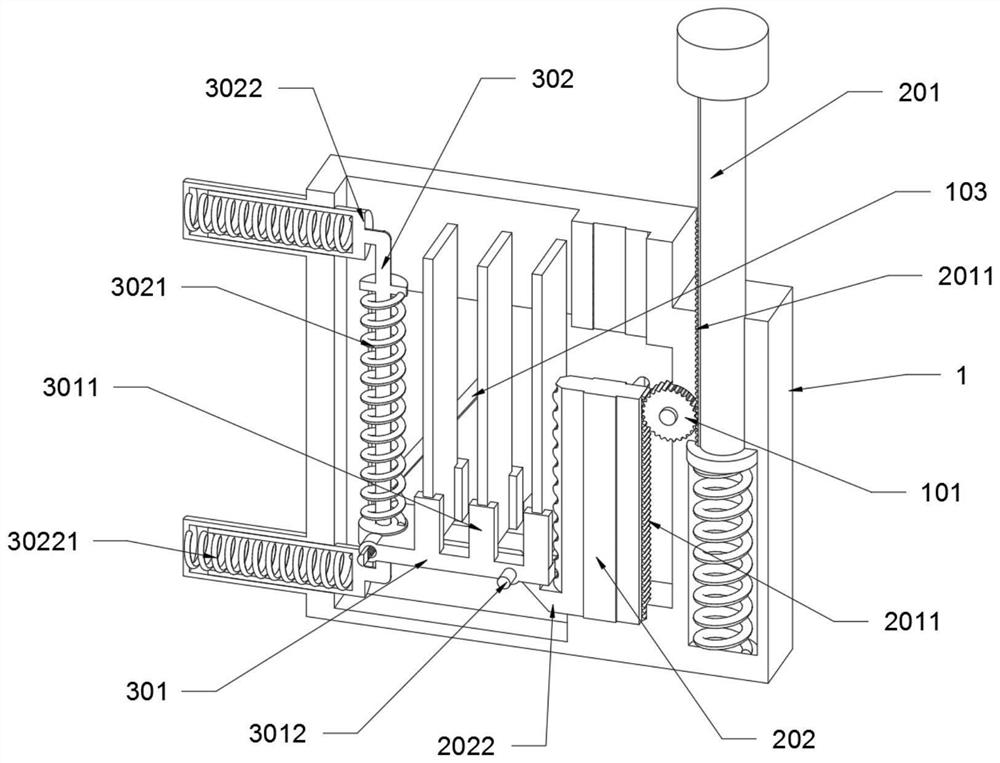

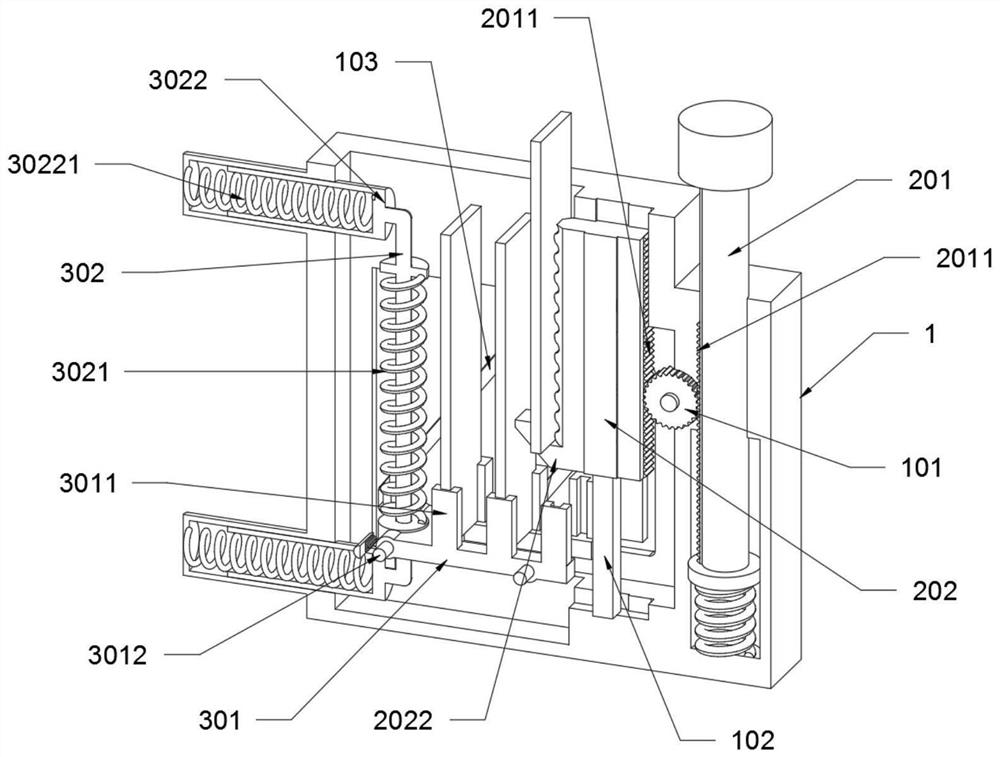

[0038] as attached figure 1 to attach Figure 5 Shown:

[0039] The present invention provides an accurate detection system for Mycobacterium tuberculosis, comprising a soaking shell 1;

[0040] The inside of the soaking shell 1 is provided with a soaking cavity, and the inside of the soaking cavity is filled with ethanol, and the inside of the soaking shell 1 is equipped with a taking control component 2 and a bearing degreasing component 3;

[0041] The taking control assembly 2 includes a lifting control rod 201 and a linkage lifting block 202. The lifting control rod 201 is plugged into the inside of one side of the soaking shell 1, and the linkage lifting block 202 is plugged into the inside of the soaking shell 1. The lifting control rod 201 The bottom is fixedly connected with a lifting top spring;

[0042] The carrying and degreasing assembly 3 includes a slide carrying tray 301 and a position control rod 302, the slide carrying tray 301 is plugged into the soaking ...

Embodiment 2

[0047] as attached figure 1 To attach Figure 8 shown

[0048] On the basis of Embodiment 1, a track bar 3012 is provided inside the disc body of the glass slide carrying tray 301, and a track groove 103 is provided inside the housing of the soaking shell 1, and the groove body shape of the track groove 103 is a triangular design, and the track The rod 3012 is plugged into the track groove 103, and the track groove 103 can ensure that the device can be used repeatedly.

[0049] Wherein, the groove body of track groove 103 is provided with bottom control point a1031, bottom control point b1032 and top control point 1033 inside, and the depth of the groove body of track groove 103 at the bottom control point a1031 and bottom control point b1032 is the same, and track groove 103 The groove depth at the position of the top control point 1033 is greater than that of the track groove 103 at the position of the bottom control point a1031. When the lever 201 is controlled, the link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com